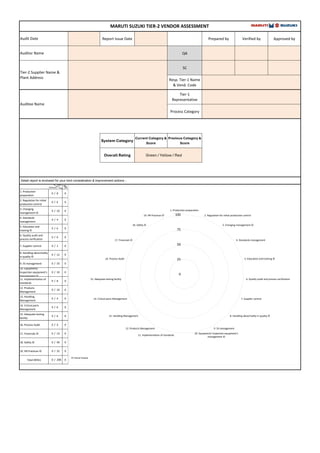

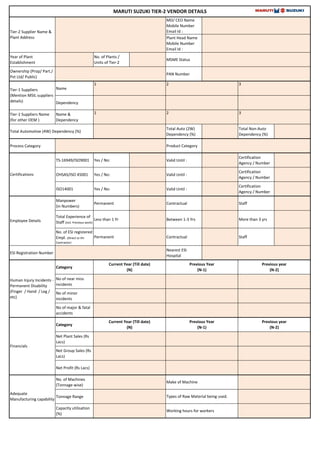

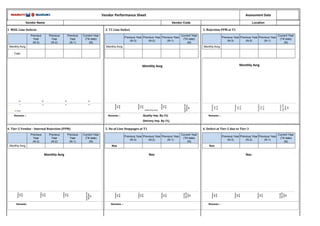

The document is a detailed assessment report for tier-2 vendors of Maruti Suzuki, focusing on various quality management and safety protocols across multiple categories. It includes scores on areas such as production preparation, initial production control, education and training, and safety practices, indicating a comprehensive audit of compliance with established standards. The overall rating reflects significant room for improvement, with many areas achieving low scores and specific recommendations for corrective actions highlighted.