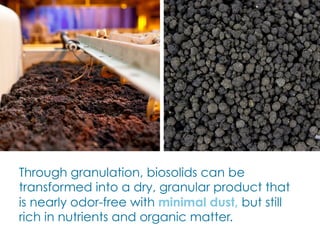

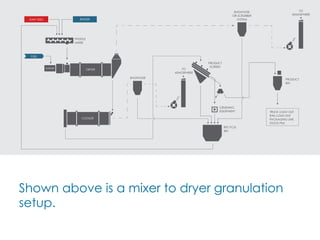

Biosolids granulation transforms challenging wastewater biosolids into a dry, nutrient-rich, and odor-free granular product. This process alleviates transportation and land application issues while providing benefits such as reduced waste management costs, improved product handling, and enhanced nutrient management. The highly customizable granulation process can produce premium fertilizer products, integrating with traditional fertilizers for tailored solutions.