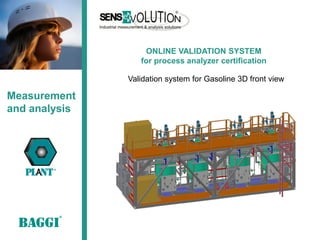

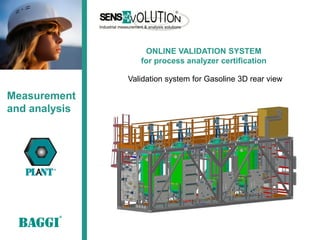

Founded in 1947, Baggi specializes in telecommunications and process measurement solutions for various industrial sectors. The company offers a wide range of customizable products and services, including consultancy, design, installation, and maintenance, emphasizing customer satisfaction and environmental sustainability. Baggi is ISO 9001:2008 certified and operates globally, providing innovative and reliable measurement and analysis systems across multiple fields.