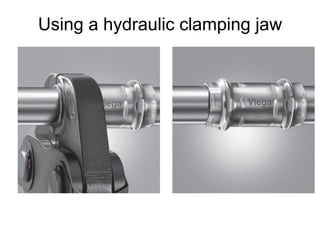

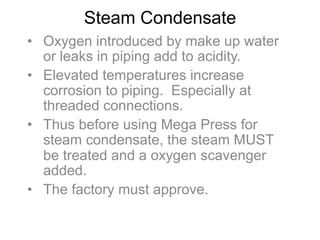

Viega developed the Mega Press system for joining black iron pipe without threading. It can be used for pipes from 1/2" to 2" for applications like natural gas, water, steam, and compressed air. The system uses hydraulic jaws to press fittings together, and is approved for pressures up to 200 psi and temperatures from -40F to 250F. For steam condensate applications, the steam must be treated with chemicals to balance the pH and prevent harming the o-rings in the fittings.