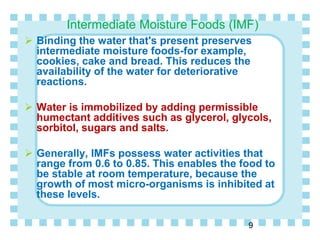

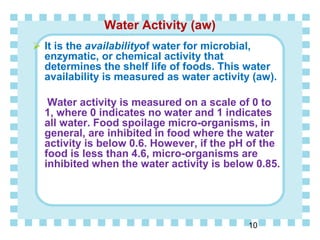

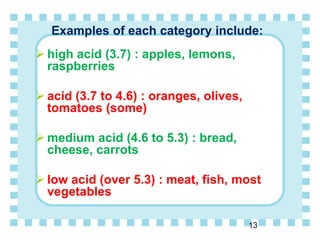

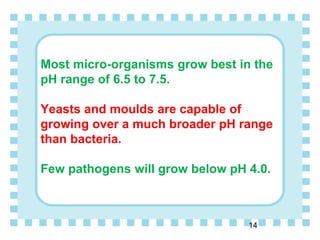

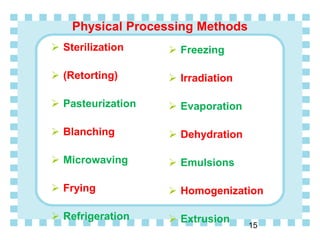

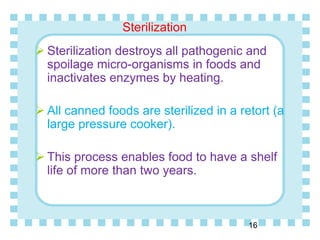

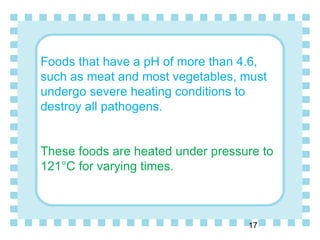

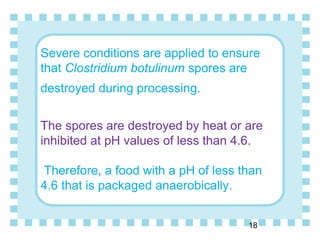

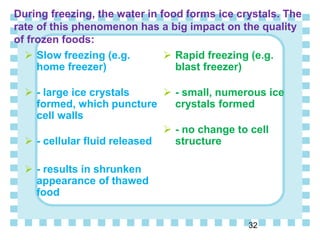

Once harvested, food begins to deteriorate due to microorganisms, enzymes, temperature, moisture, and insects. To increase availability, much food is processed to preserve it by stabilizing safety and quality. No processing can improve poor raw materials. To ensure high standards, the best raw ingredients and techniques must be used. Processing is used for preservation and to change texture. The main categories are chemical and physical methods like sterilization, pasteurization, blanching, freezing, and dehydration which use techniques like water control, addition of chemicals, and temperature adjustment to prevent spoilage.