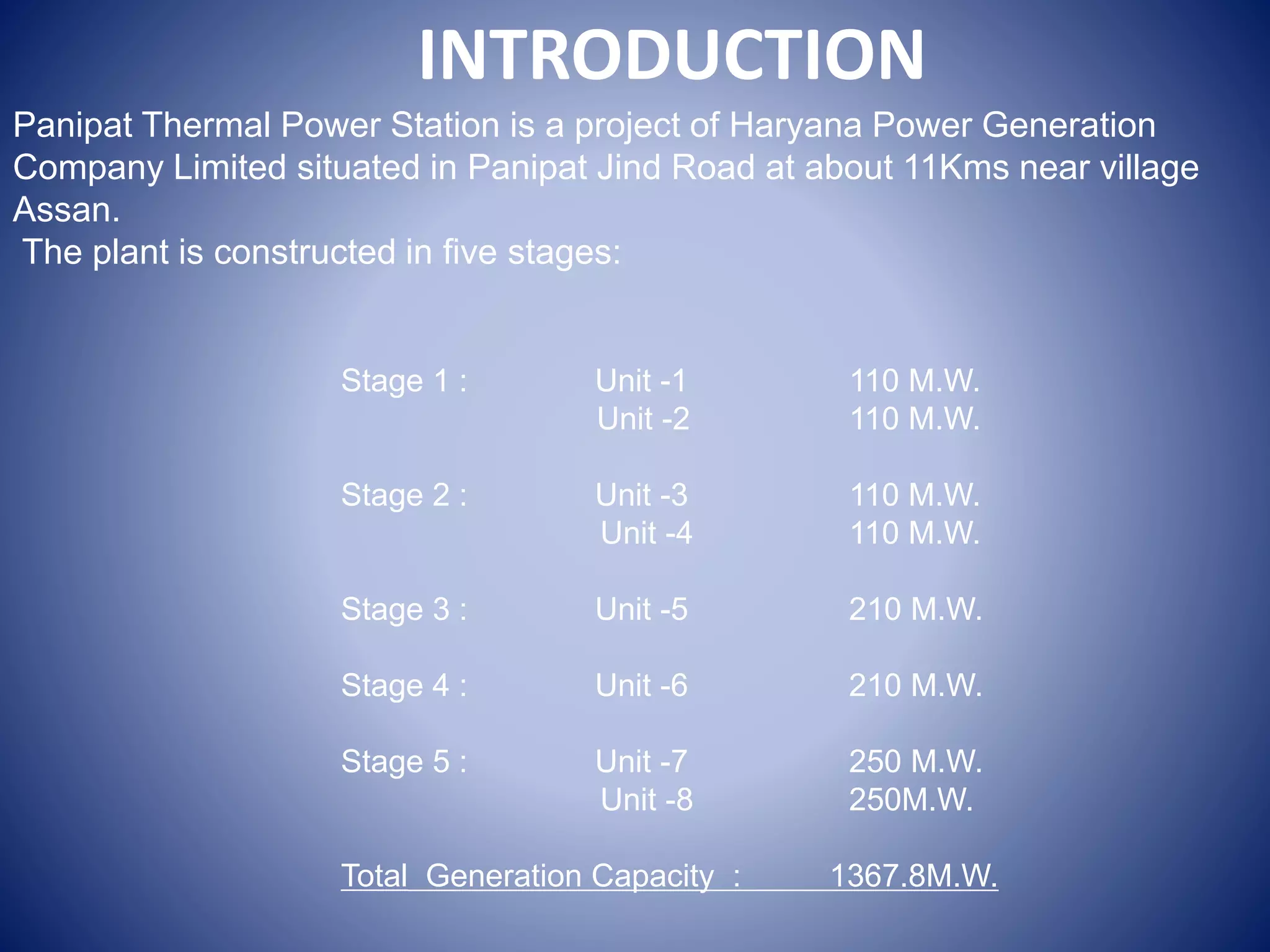

The document provides details about the Panipat Thermal Power Plant located in Panipat, India. It describes the plant's 5 construction stages and total generation capacity of 1,367.8 MW. The key components and processes of a thermal power plant are explained, including how coal is used to heat water and create steam to power the turbine and generate electricity. The plant receives coal, water, and fuel by rail, canal, and tankers which are stored and prepared before use in the boiler and generators.