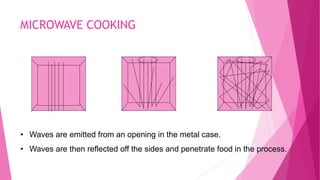

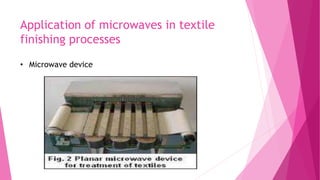

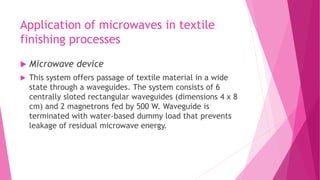

This document summarizes microwave heating and its applications. It begins with an introduction to microwaves and their properties such as their ability to reflect off conducting surfaces and attenuate over short distances. It then discusses advantages like increased bandwidth and improved directive properties. Applications mentioned include telecommunications, radar, microwave ovens for cooking, and industrial uses like drying in textiles. The document provides details on how microwave ovens work and their limitations such as not being able to pass through metal. It concludes with examples of microwave technology used in textile finishing processes for desizing, scouring, bleaching, and drying fabrics uniformly.