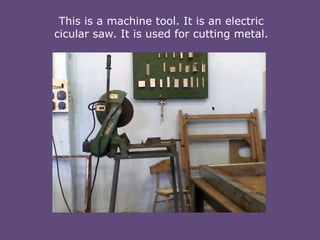

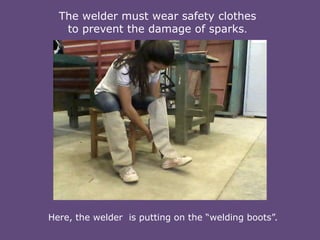

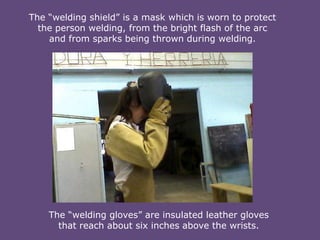

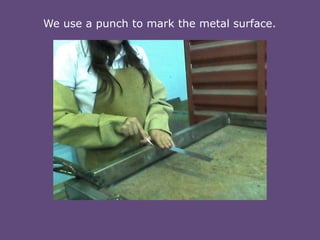

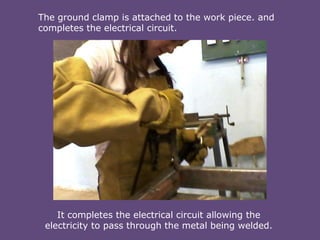

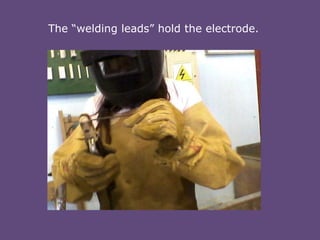

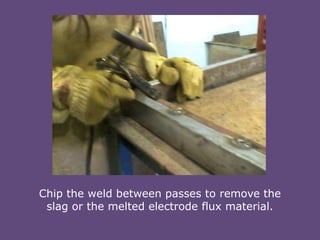

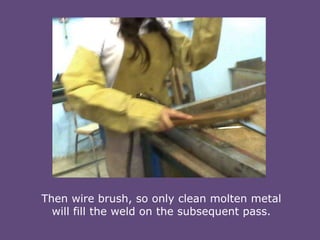

The document outlines the tools, materials, and safety equipment necessary for a welding workshop, emphasizing the importance of workspace organization and safety measures. It describes specific tools like arc welding machines, cutting saws, and protective gear like welding leathers and gloves. It concludes with a step-by-step process for completing a window frame through proper welding techniques over two weeks.