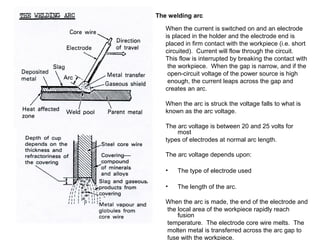

Manual metal arc welding, also known as stick welding, involves an electrode coated in flux that is struck by an electric arc to melt and join metal workpieces. It was first developed in the late 1800s using bare metal rods but switched to coated electrodes in the early 1900s which improved weld quality. Electrodes are divided into cellulosic, rutile, and basic types which have different characteristics like burn rate and positional welding capabilities. While once the most common welding process, MIG and MAG welding have now surpassed manual metal arc welding in many applications.