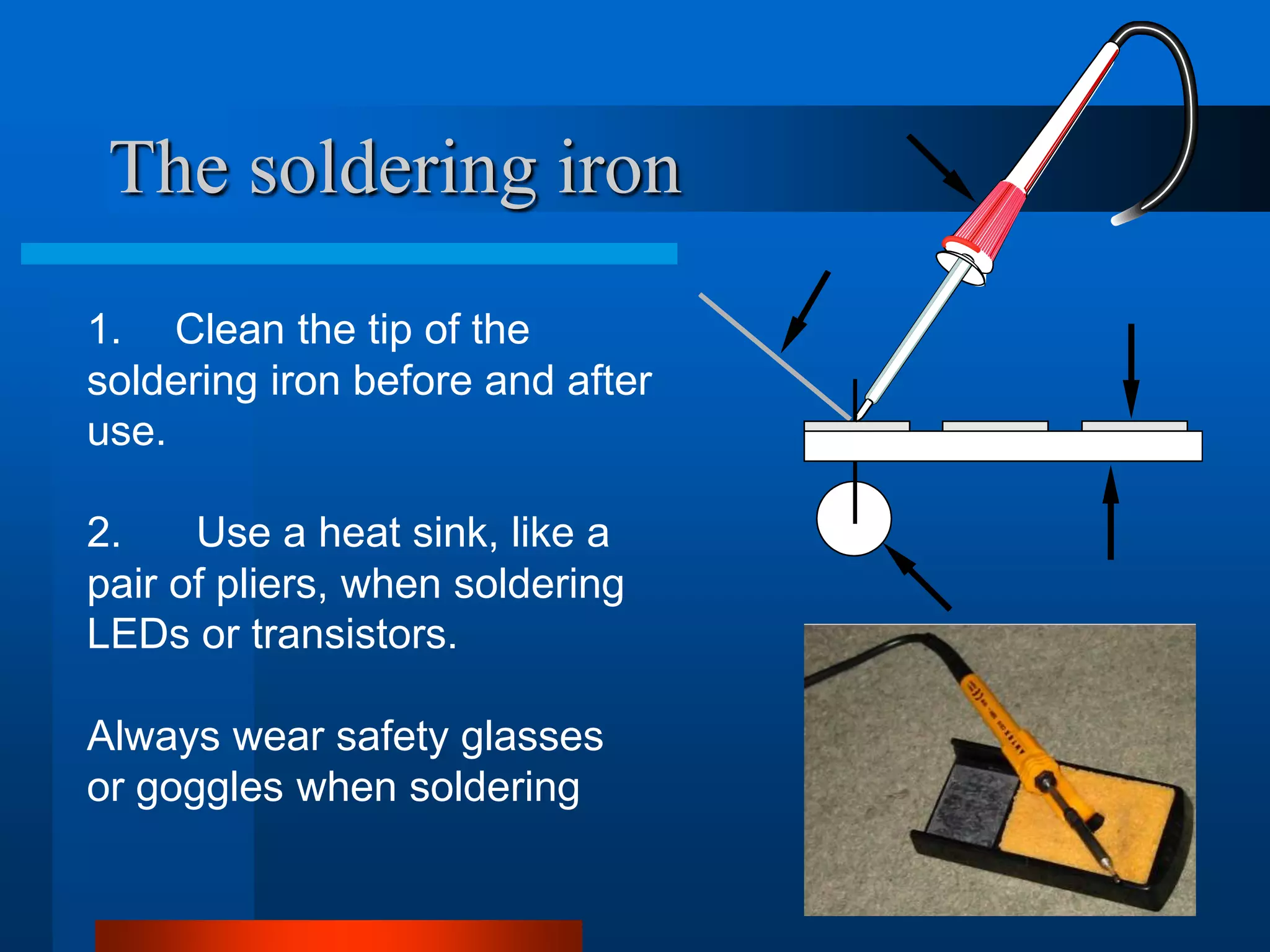

The document provides instructions for safely soldering electronic components. It explains that soldering involves heating both the component leads and circuit tracks with the hot soldering iron tip simultaneously before applying solder to form a secure joint. Proper safety precautions when soldering include wearing eye protection, avoiding touching the hot iron tip, working in a well-ventilated area, and washing hands after use due to the lead content in standard solder.