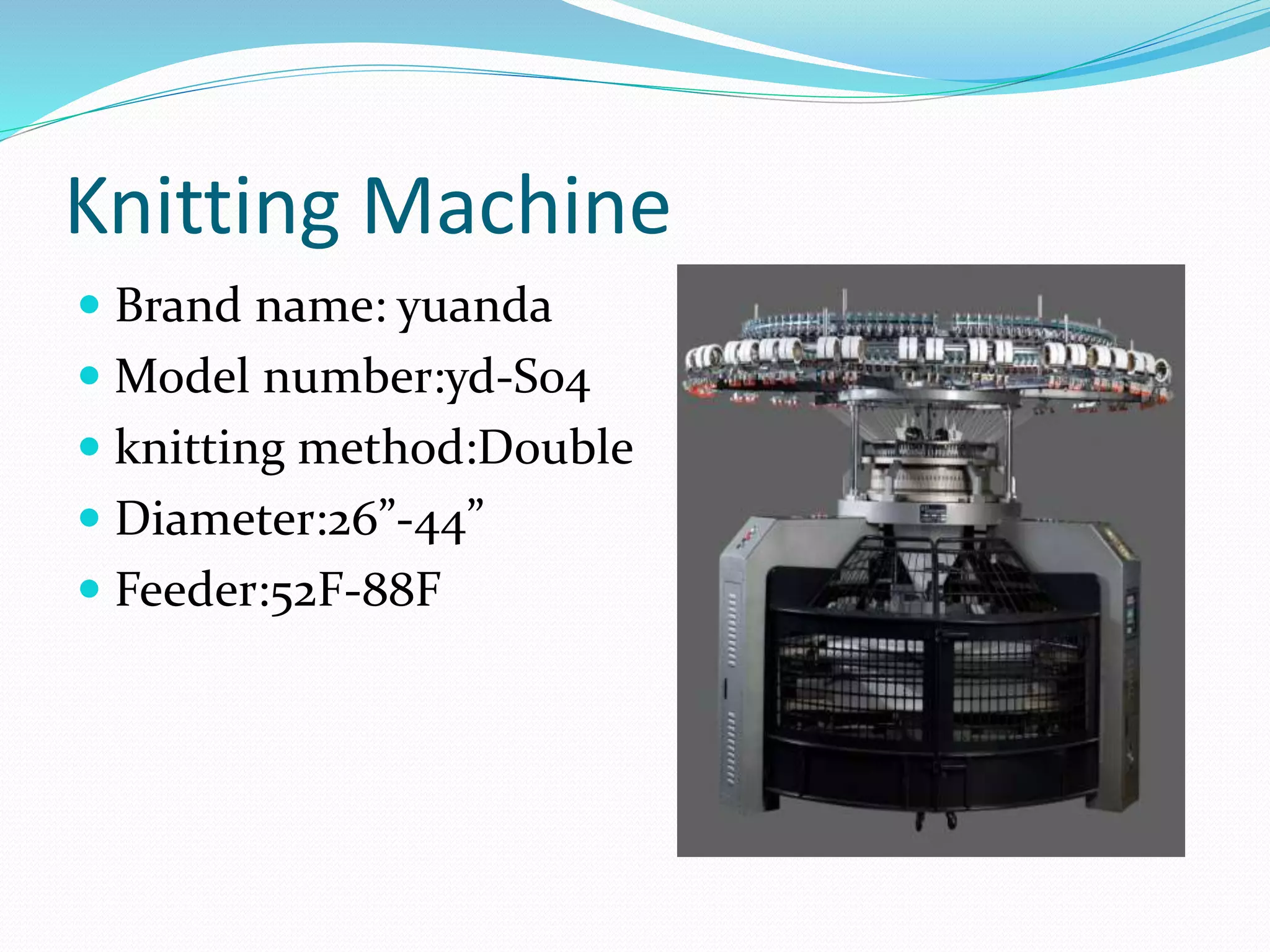

The document discusses various machines used during the Industrial Revolution and for textile manufacturing. It provides details on knitting machines, weaving machines, printing machines, and spinning machines. It also discusses the steam engine, which became widely used during the Industrial Revolution and powered other industrial machines. The document focuses on the types and specifications of different machines for knitting, weaving, printing, and spinning textile fibers into yarn and fabrics.