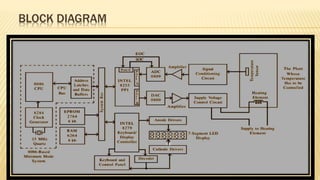

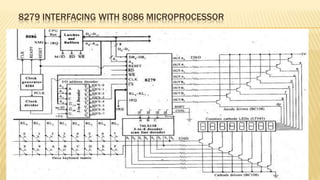

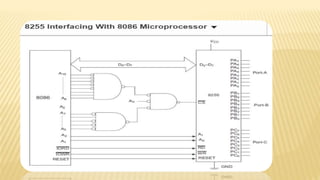

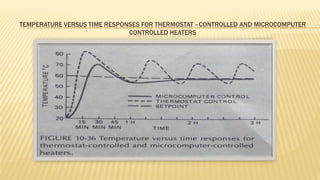

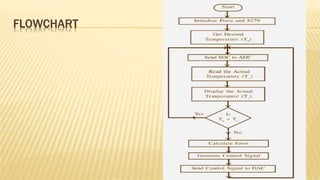

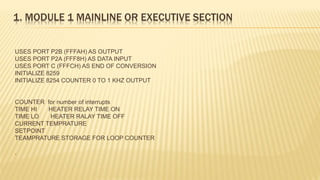

This document describes a temperature control system using an 8086 microprocessor. It includes a block diagram of the components, including an 8279 interfacing with the 8086 microprocessor. It also includes flowcharts and descriptions of the program modules, including an executive section in Module 1 that initializes components and stores temperature and timing variables. Module 2 contains interrupt service procedures, Module 3 contains loop service procedures like temperature control, and Module 4 includes utility procedures like LED display and A/D conversion. The goal is to use this system to maintain the required temperature in industrial processes by controlling heaters based on feedback from temperature sensors.