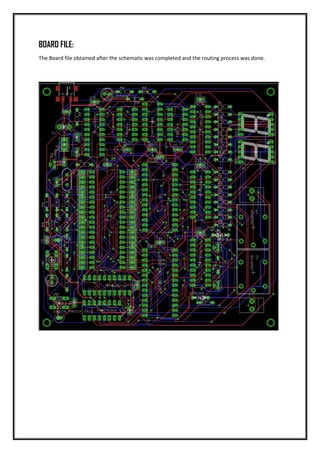

This document describes an automatic temperature control and readout project created by two students. The project uses an Intel 8085 microprocessor to display the current temperature and control/maintain the temperature of a plant or home within a desired limit. The system includes a temperature input unit with an LM135 temperature sensor and ADC0801 analog-to-digital converter, a processing unit with the 8085 microprocessor, and a control output unit with relays. The system operates by turning a heater on or fan off depending on whether the measured temperature exceeds the upper or lower set points.

![8085: The Microprocessor

The 8085 is a conventional von Neumann design based on the Intel 8080. Unlike the 8080 it does not

multiplex state signals onto the data bus, but the 8-bit data bus is instead multiplexed with the lower

8-bits of the 16-bit address bus to limit the number of pins to 40. State signals are provided by

dedicated bus control signal pins and two dedicated bus state ID pins named S0 and S1. Pin 40 is

used for the power supply (+5 V) and pin 20 for ground. Pin 39 is used as the Hold pin. Pins 15 to 8

are generally used for address buses.[clarification needed] The processor was designed using nMOS

circuitry, and the later "H" versions were implemented in Intel's enhanced nMOS process called

HMOS ("High-performance MOS"), originally developed for fast static RAM products. Only a single 5

volt power supply is needed, like competing processors and unlike the 8080. The 8085 uses

approximately 6,500 transistors

The 8085 has extensions to support new interrupts, with three mask able vectored interrupts (RST

7.5, RST 6.5 and RST 5.5), one non-mask able interrupt (TRAP), and one externally serviced interrupt

(INTR). Each of these five interrupts has a separate pin on the processor, a feature which permits

simple systems to avoid the cost of a separate interrupt controller.

The processor has seven 8-bit registers accessible to the programmer, named A, B, C, D, E, H, and L,

where A is the 8-bit accumulator and the other six can be used as independent byte-registers or as](https://image.slidesharecdn.com/70-87-2016-fpr-211203082955/85/Microprocessor-project-7-320.jpg)