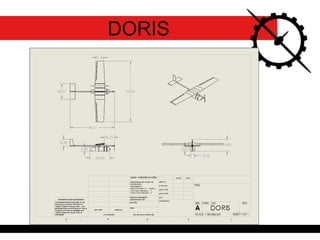

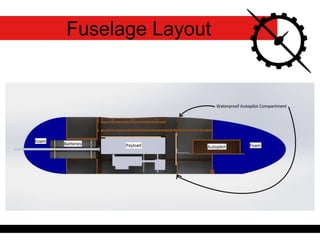

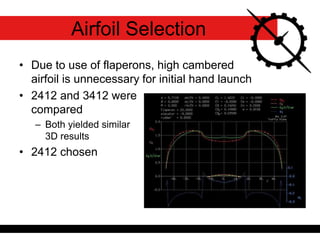

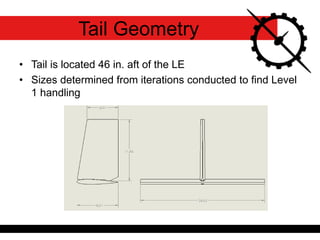

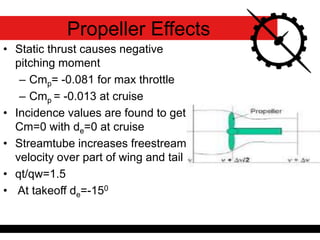

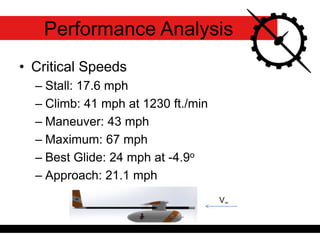

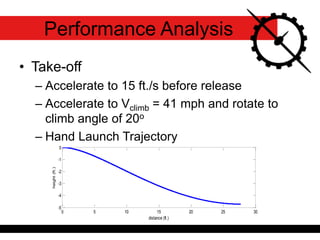

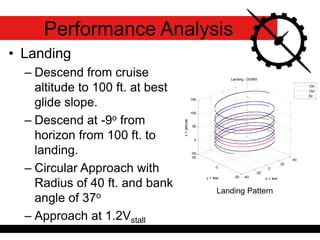

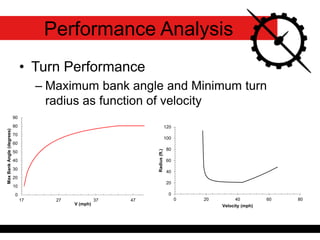

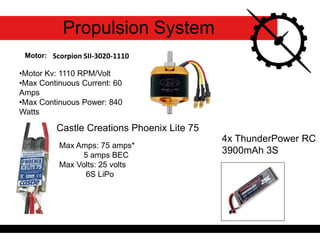

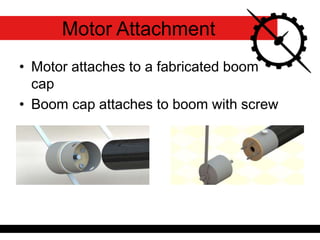

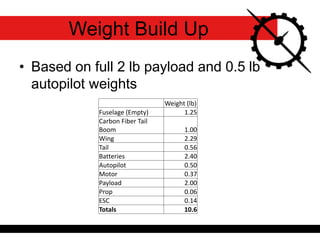

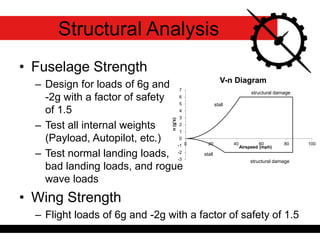

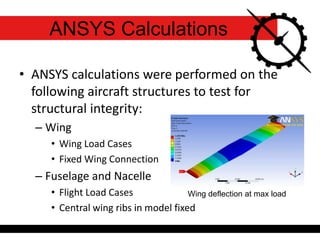

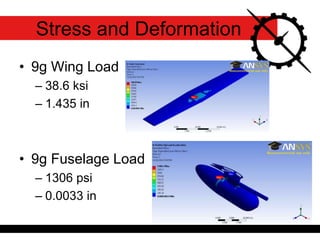

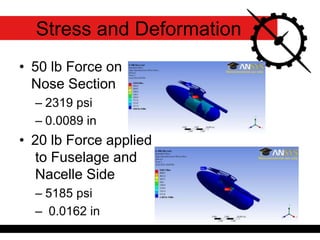

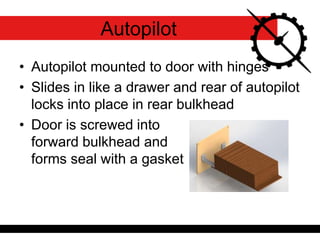

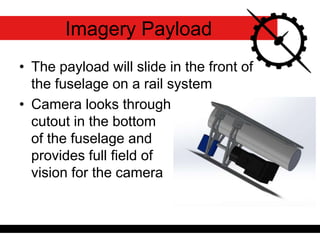

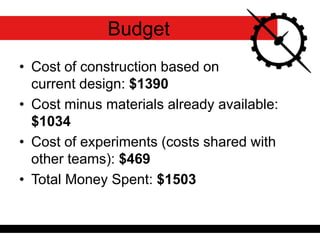

The team presented the critical design review for DORIS, a deployable oceanic reconnaissance information system. DORIS can be launched from land or boats and breaks down into four pieces for transport and storage. It has LED lights, a payload bay, and an autopilot system. Performance analyses showed the aircraft has a 103 minute endurance at 25 mph and a 43 mile range. Structural analyses found the wing and fuselage can withstand flight loads with a 1.5 safety factor. The team's $1503 budget covers construction and shared experimental costs.