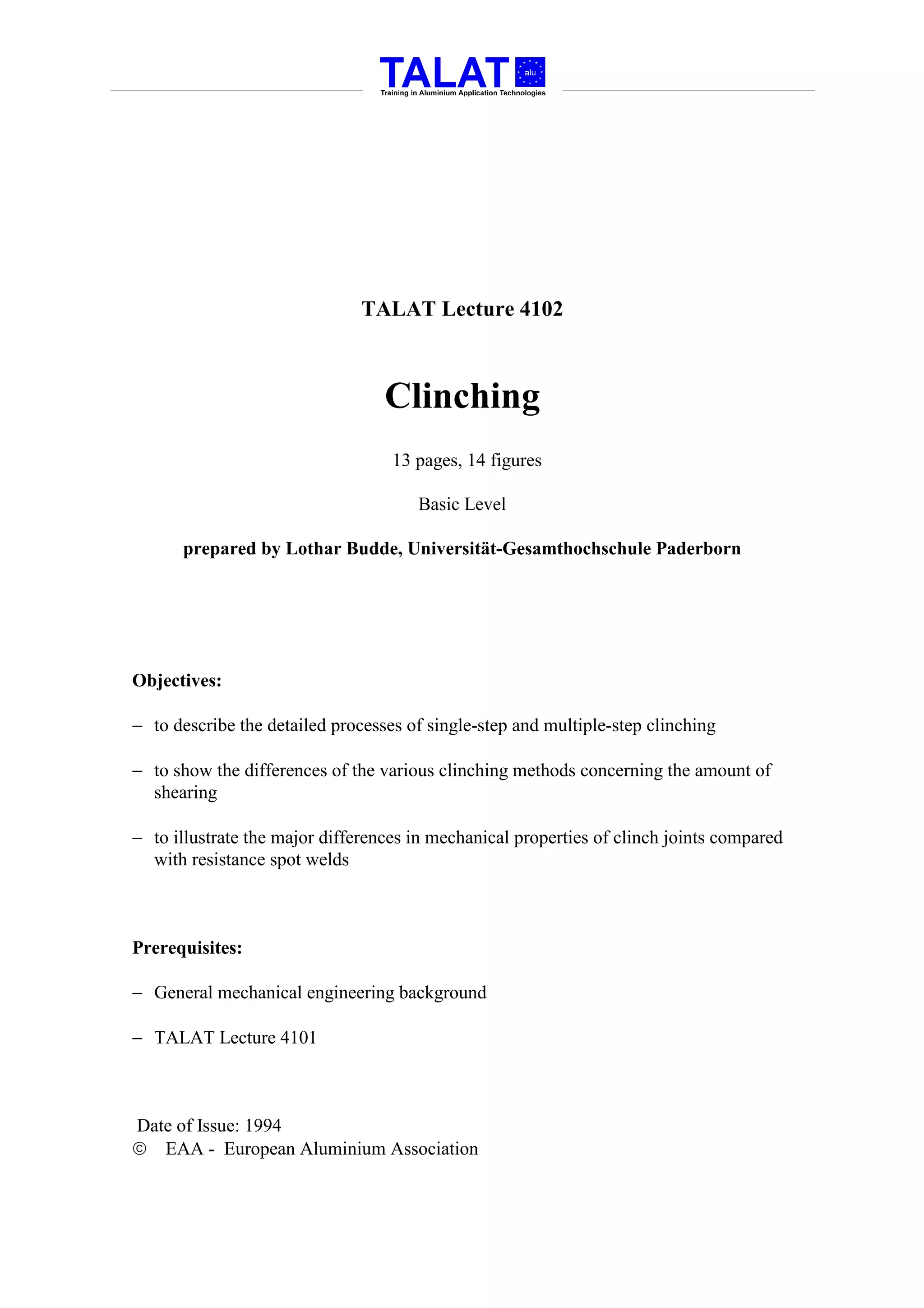

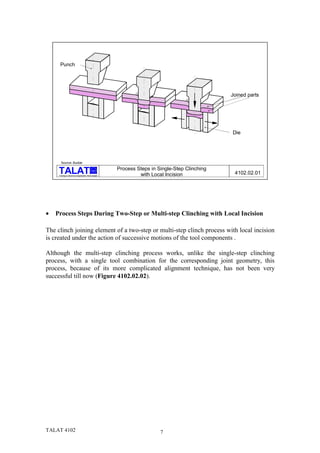

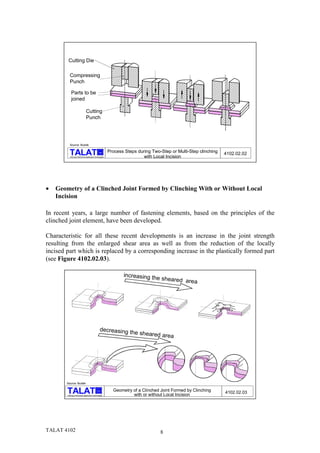

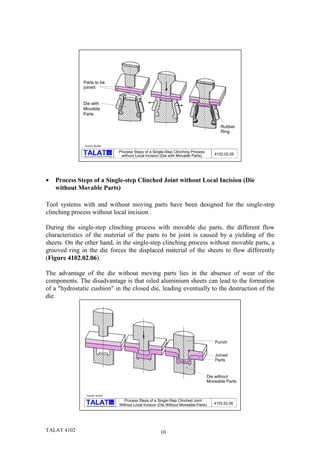

The document provides an extensive overview of clinching technology for joining materials, detailing various clinching methods, processes, and the mechanical properties of clinch joints compared to resistance spot welds. It covers definitions, classifications, and the steps involved in both single-step and multi-step clinching, including effects of local incisions and geometric considerations. The lecture is aimed at those with a mechanical engineering background and serves as a foundational resource for understanding advanced joining techniques.