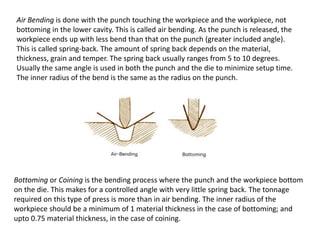

The document discusses various sheet metal processes including bending, shearing, staking, and stamping. It provides details on:

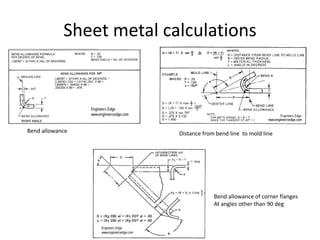

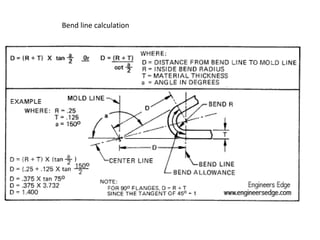

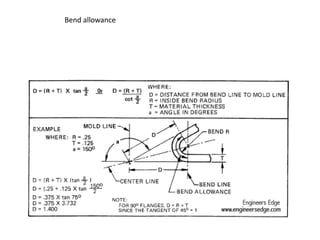

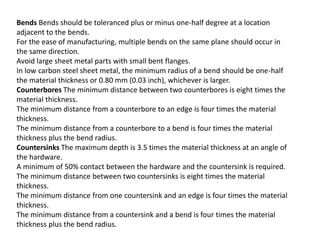

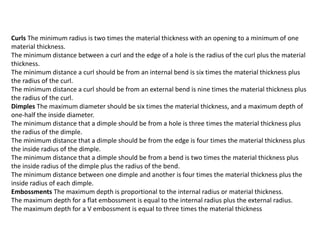

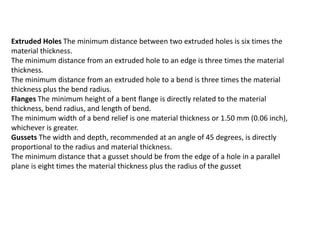

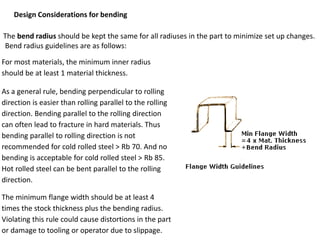

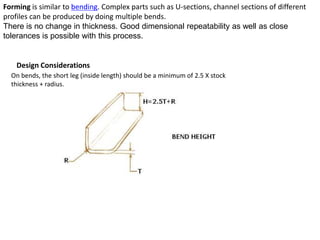

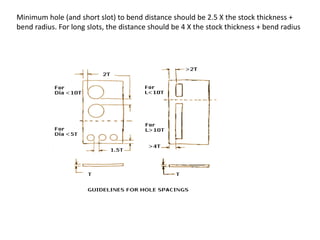

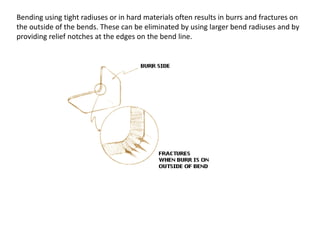

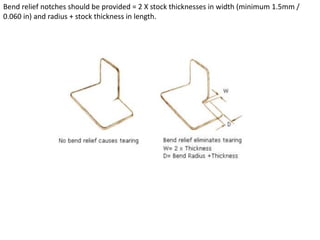

- How bending changes the shape of metal by plastic deformation within the material's yield strength. Press brakes are commonly used and allow a variety of shapes.

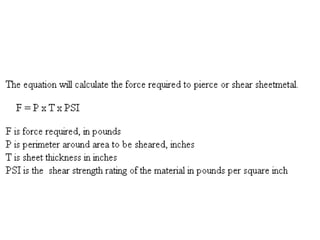

- Shearing is used to cut sheet metal to size from stock. It produces a burr that can be minimized to less than 10% of material thickness.

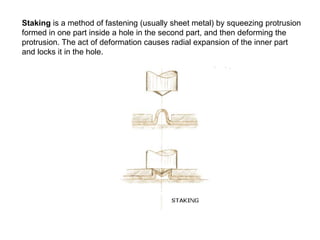

- Staking is used to fasten sheet metal by squeezing a protrusion into a hole and deforming it to lock the parts together.

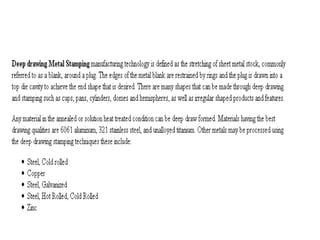

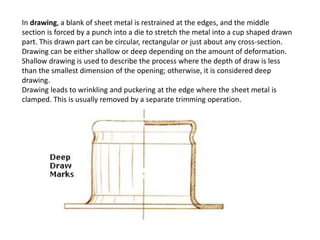

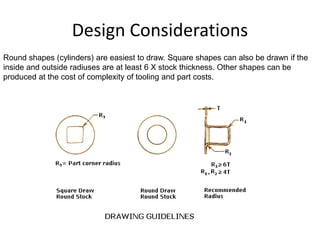

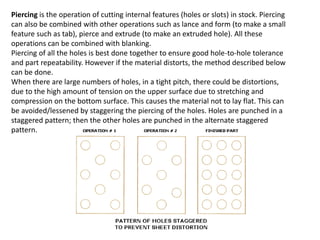

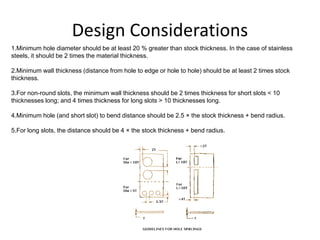

- Stamping operations include blanking, piercing, forming, and drawing using dedicated tooling. It can