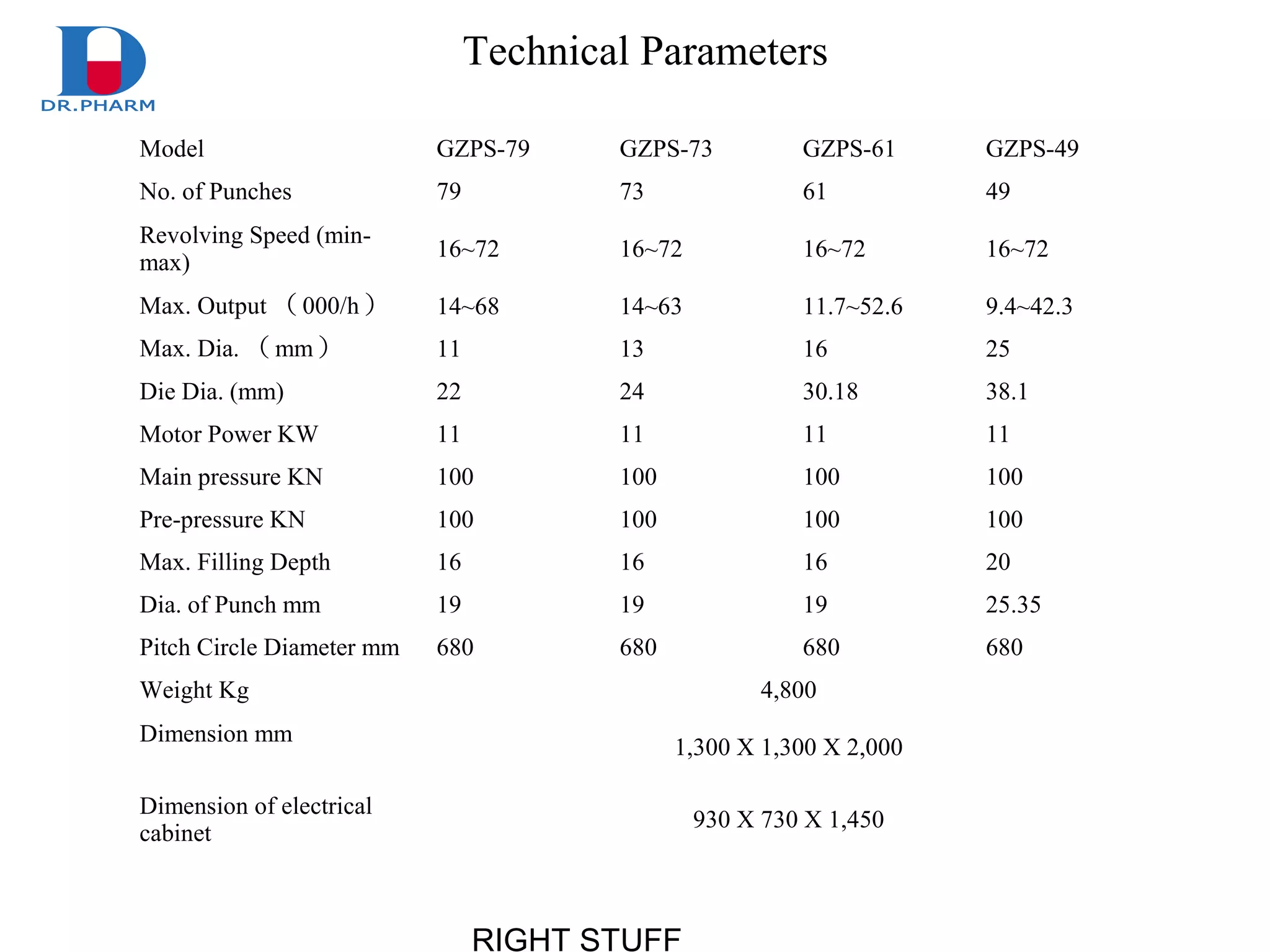

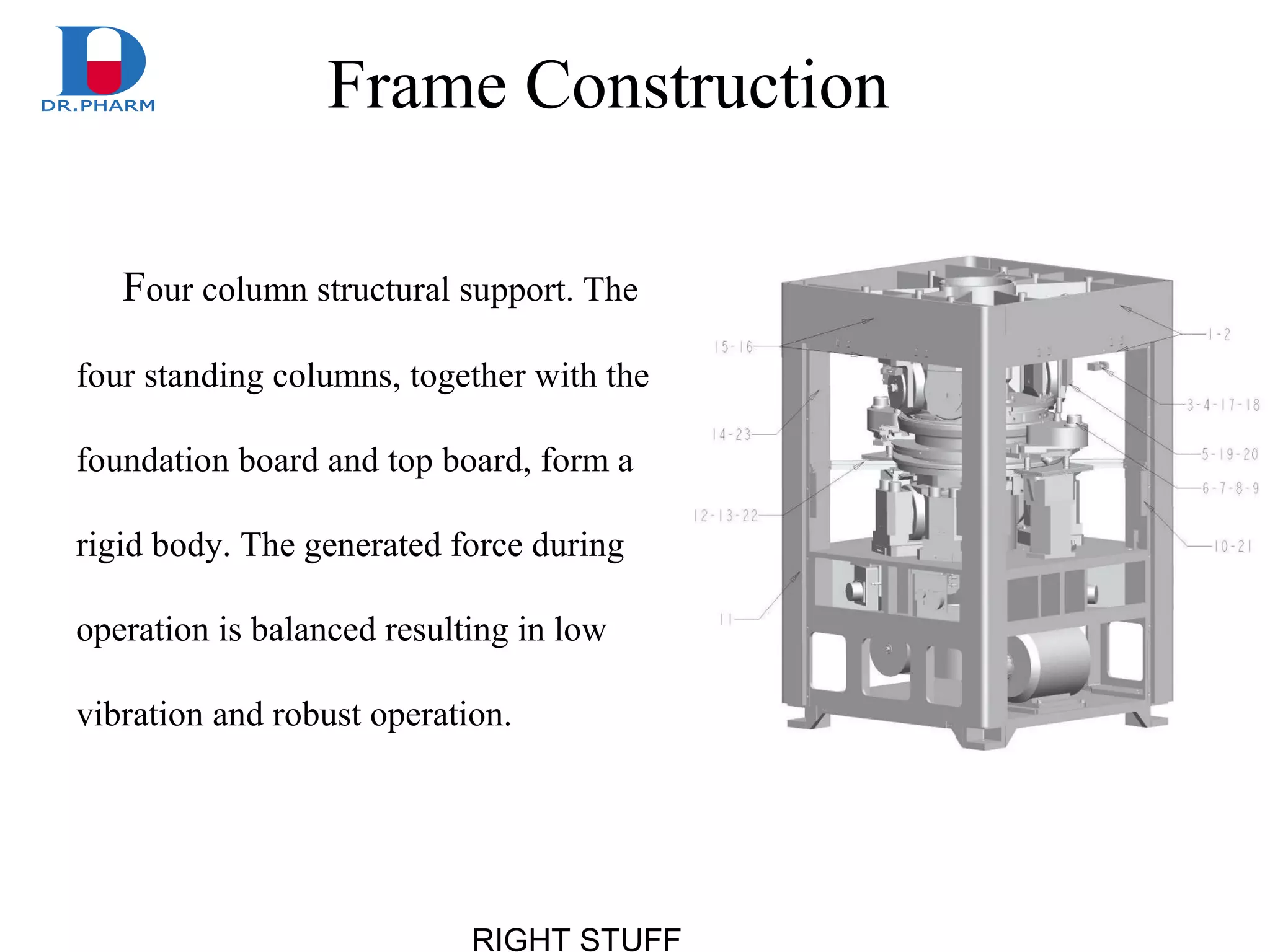

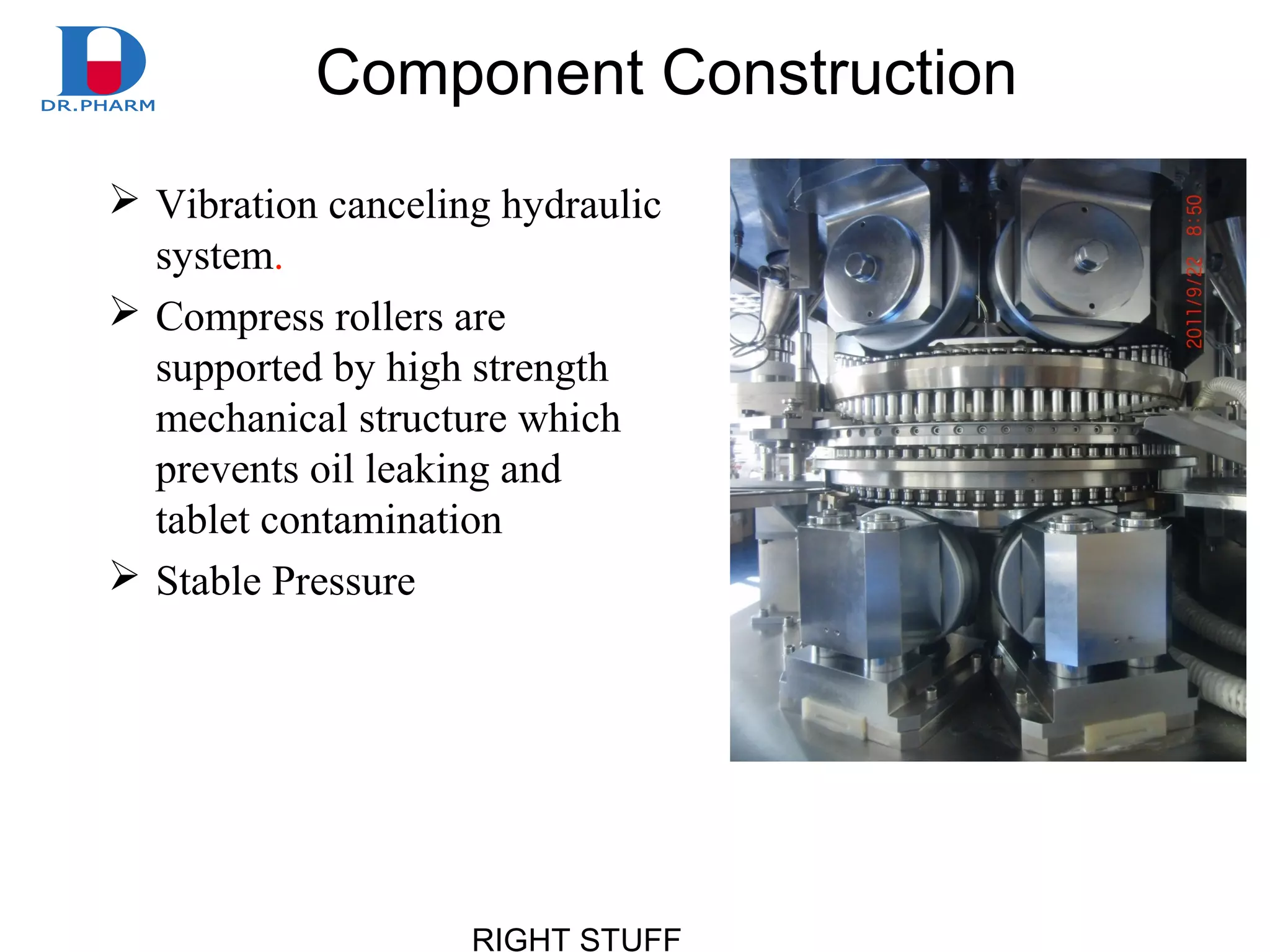

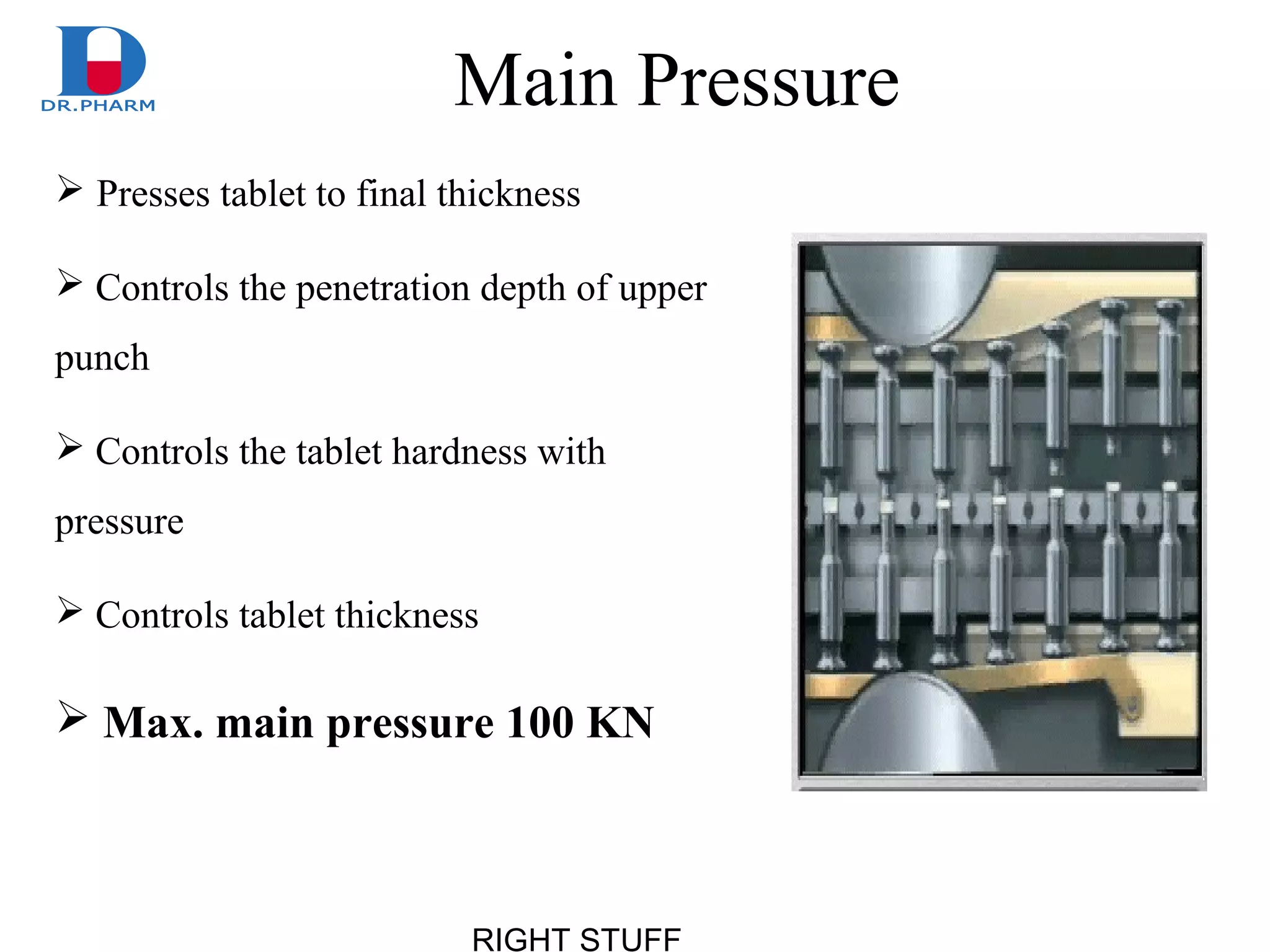

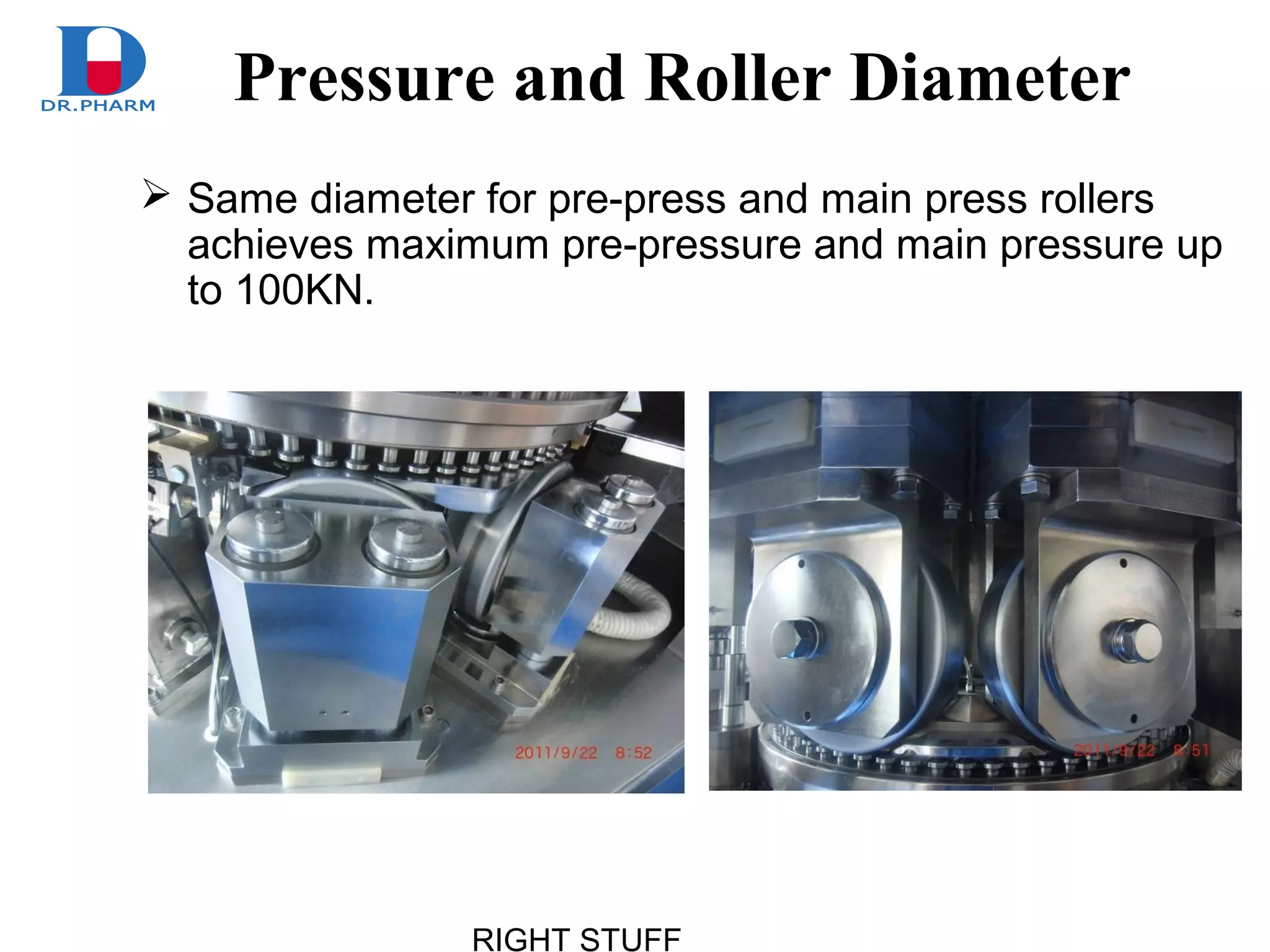

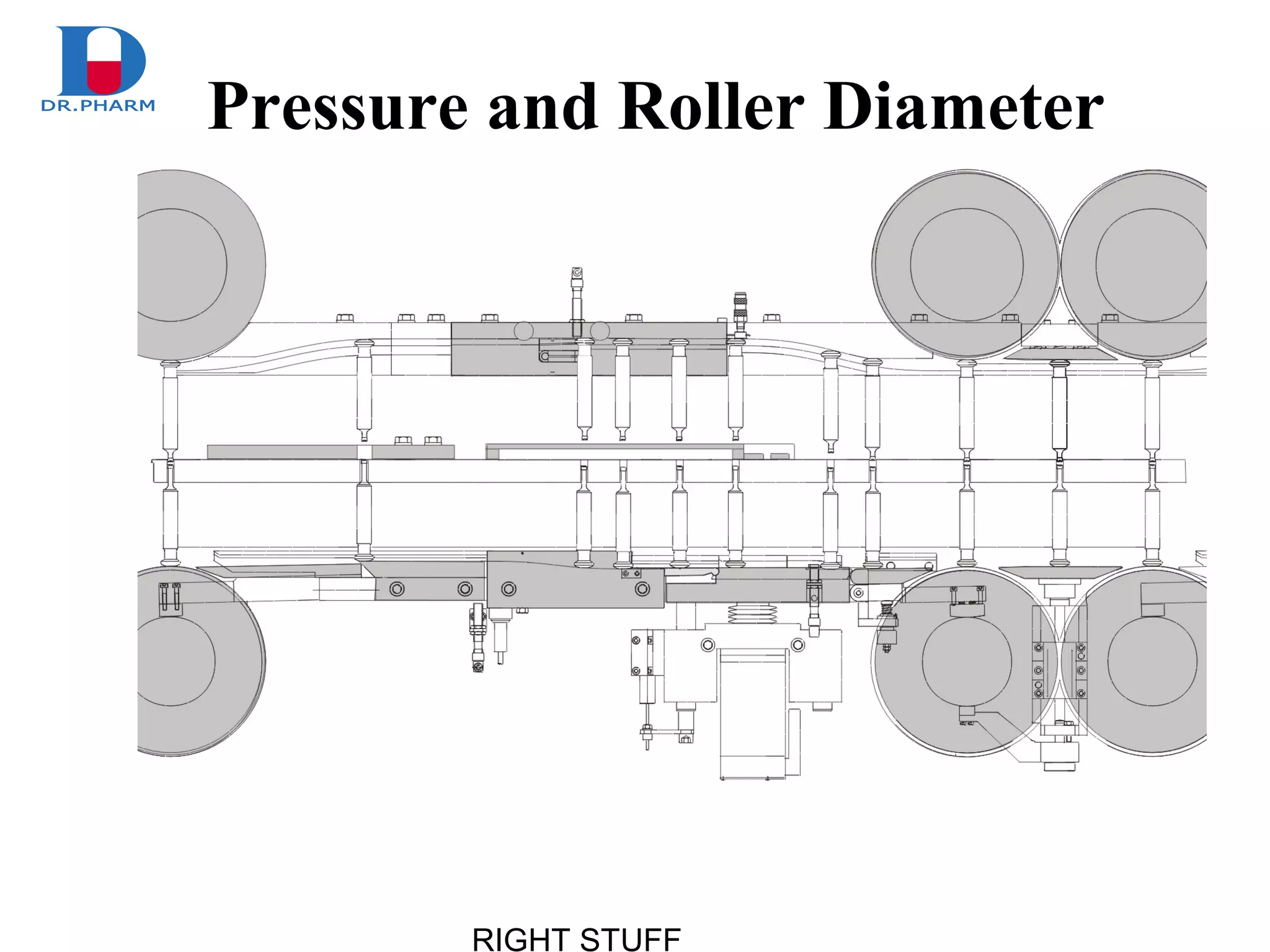

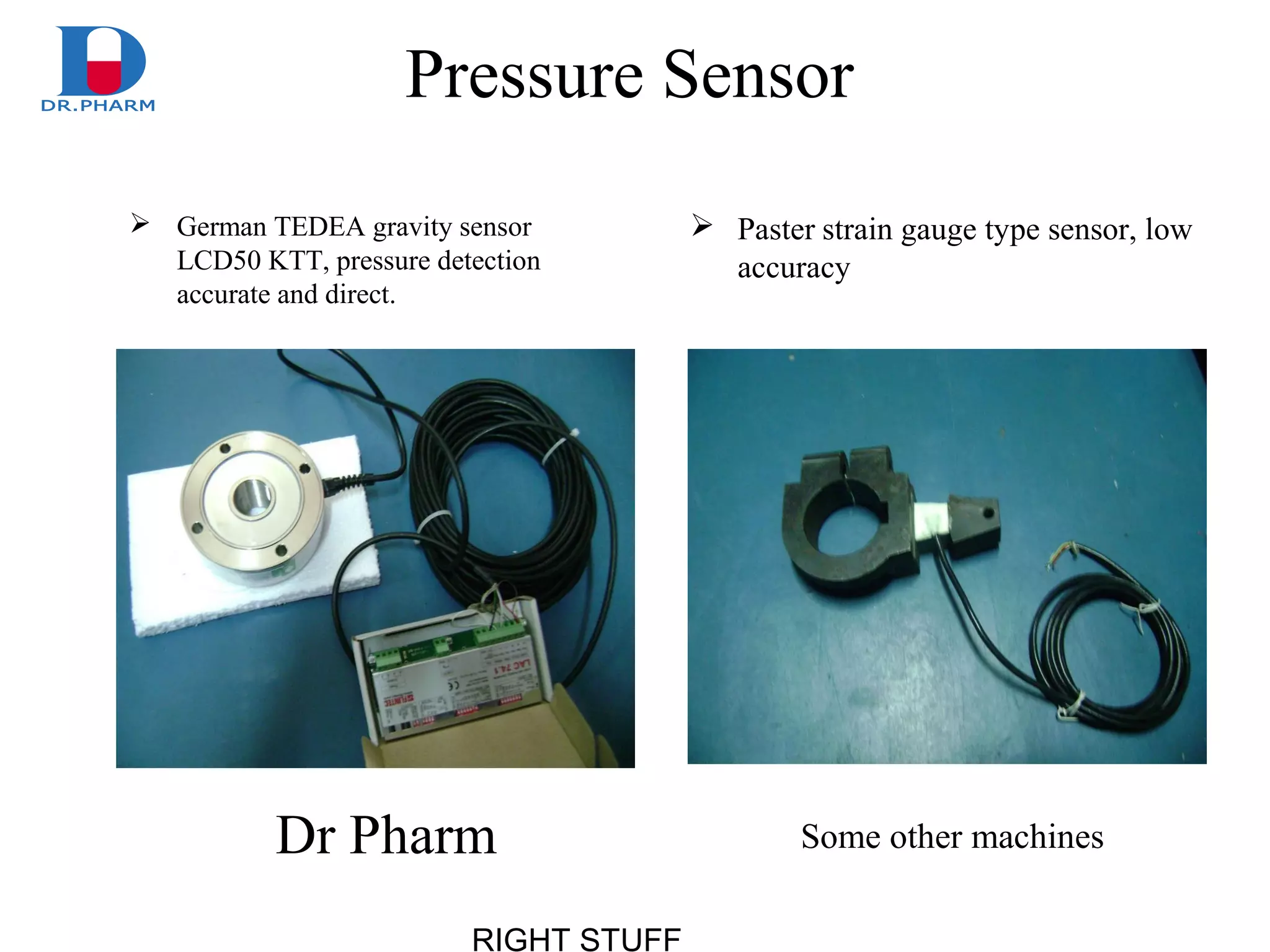

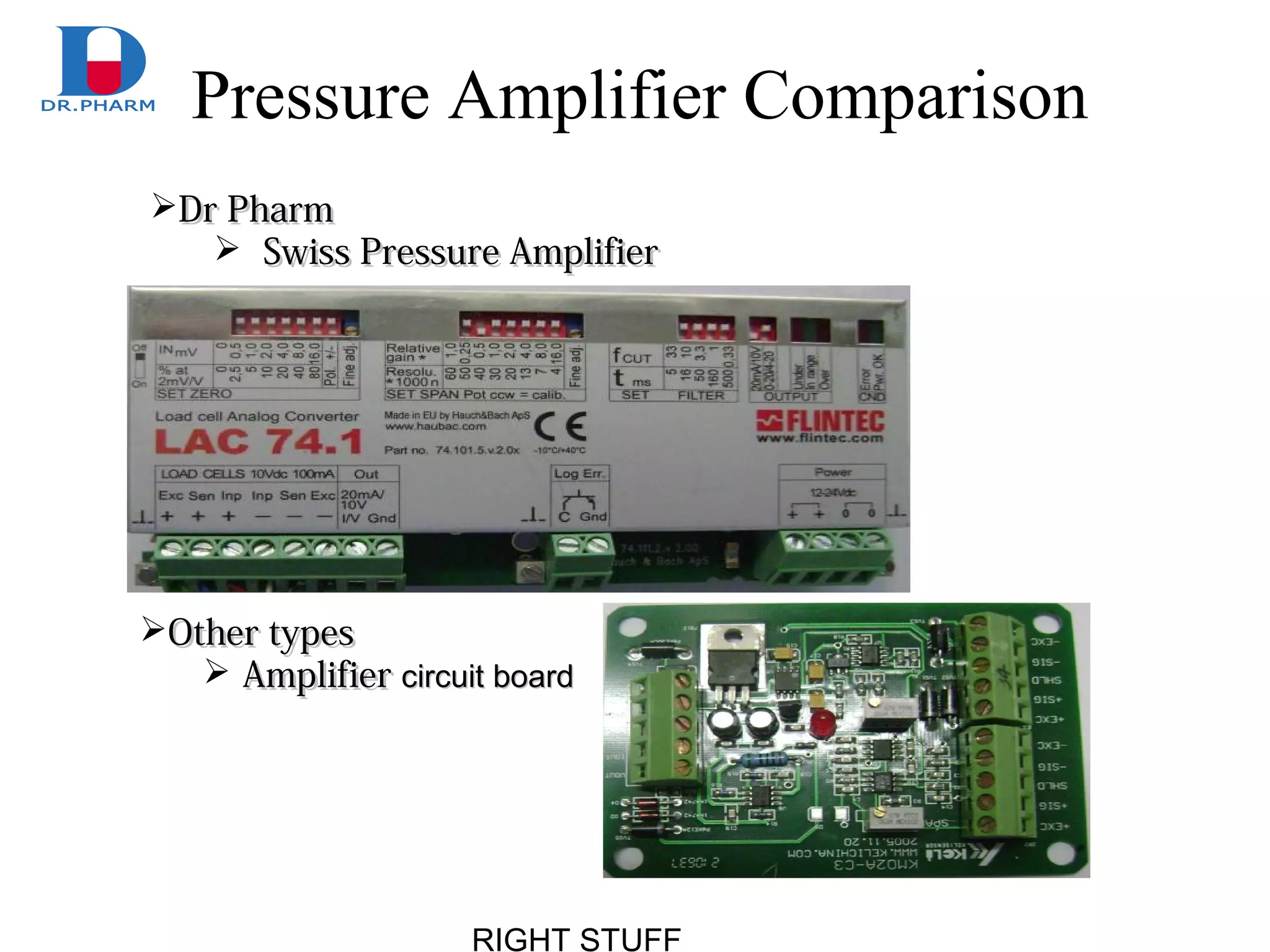

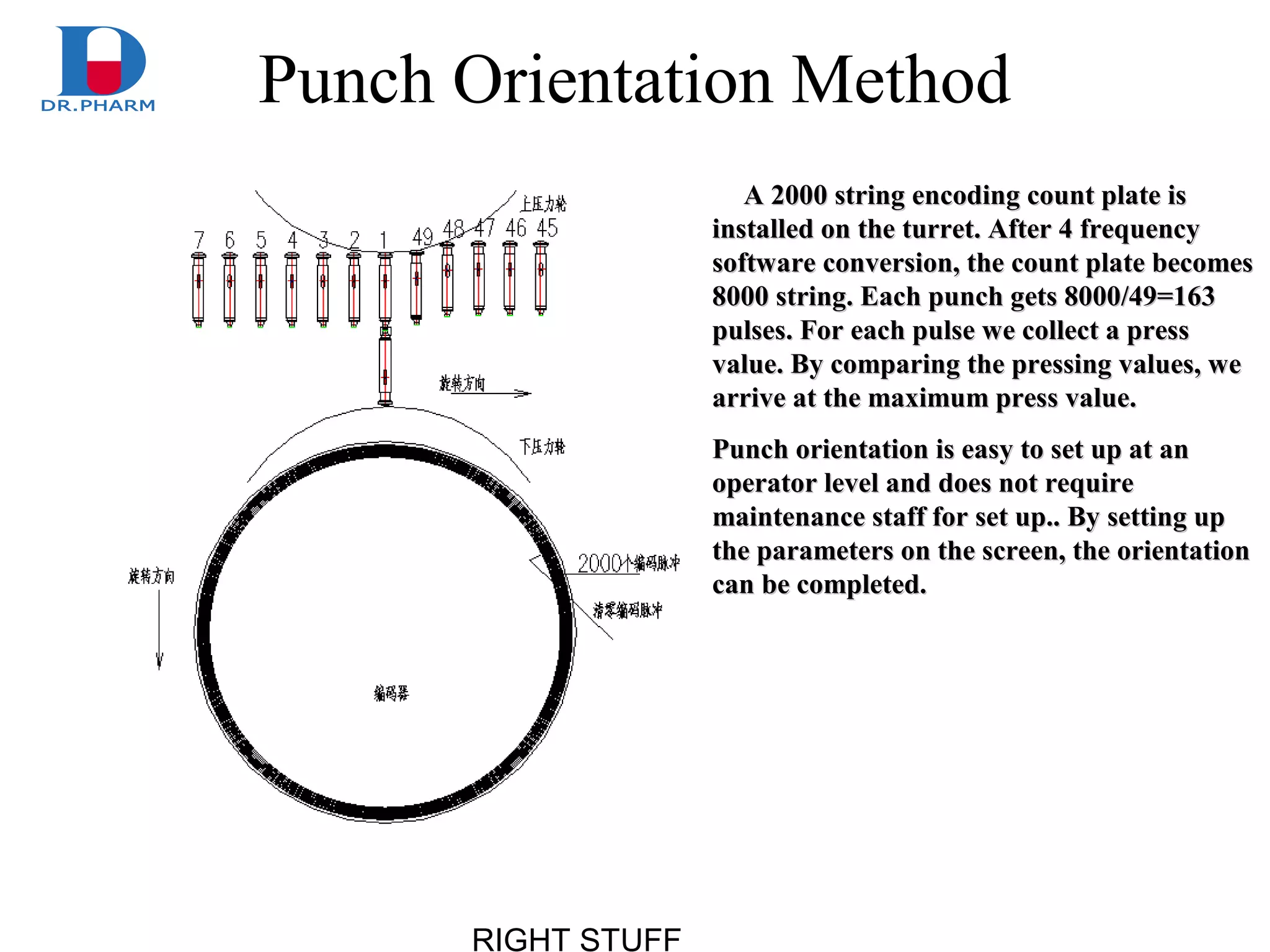

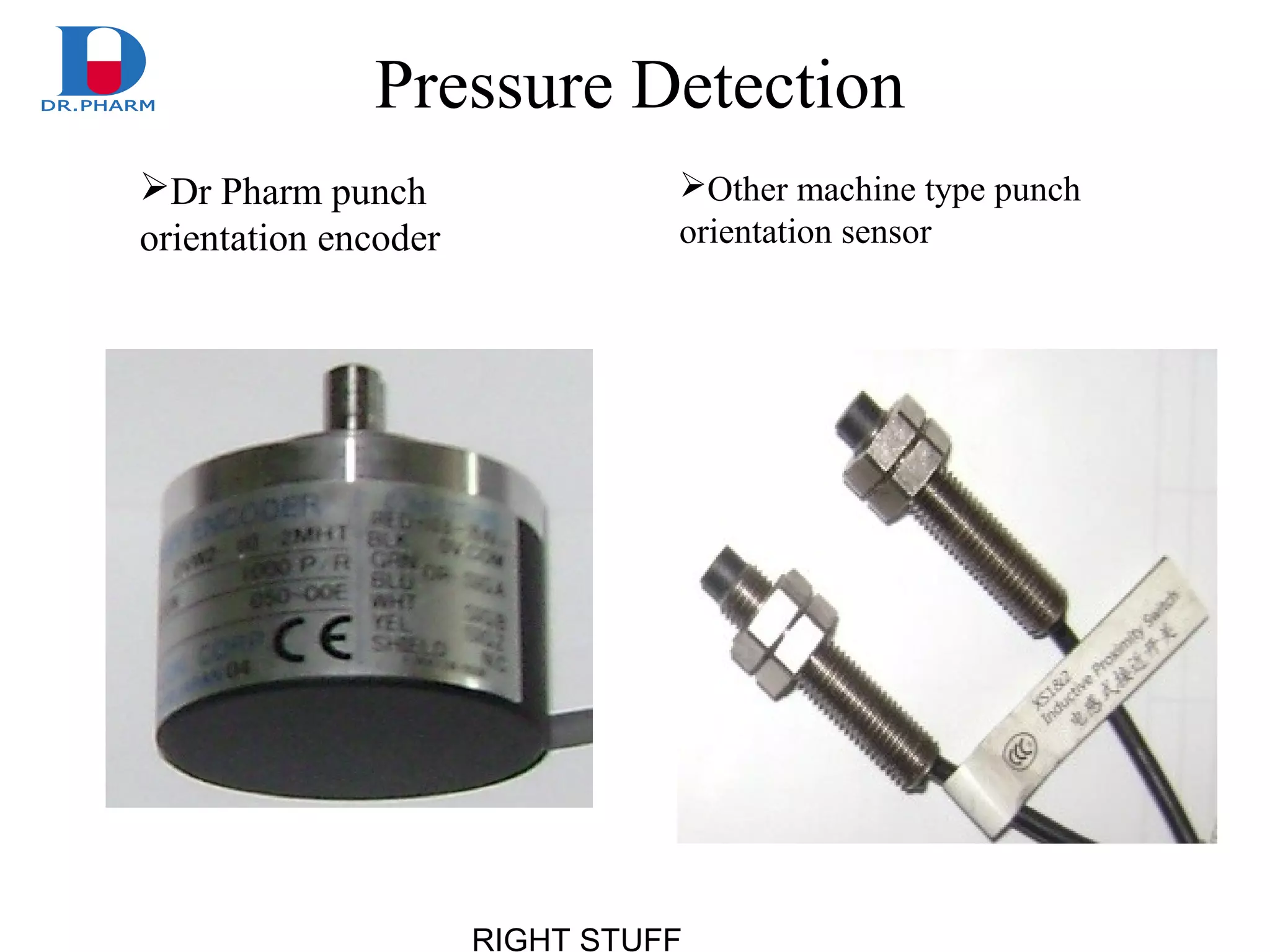

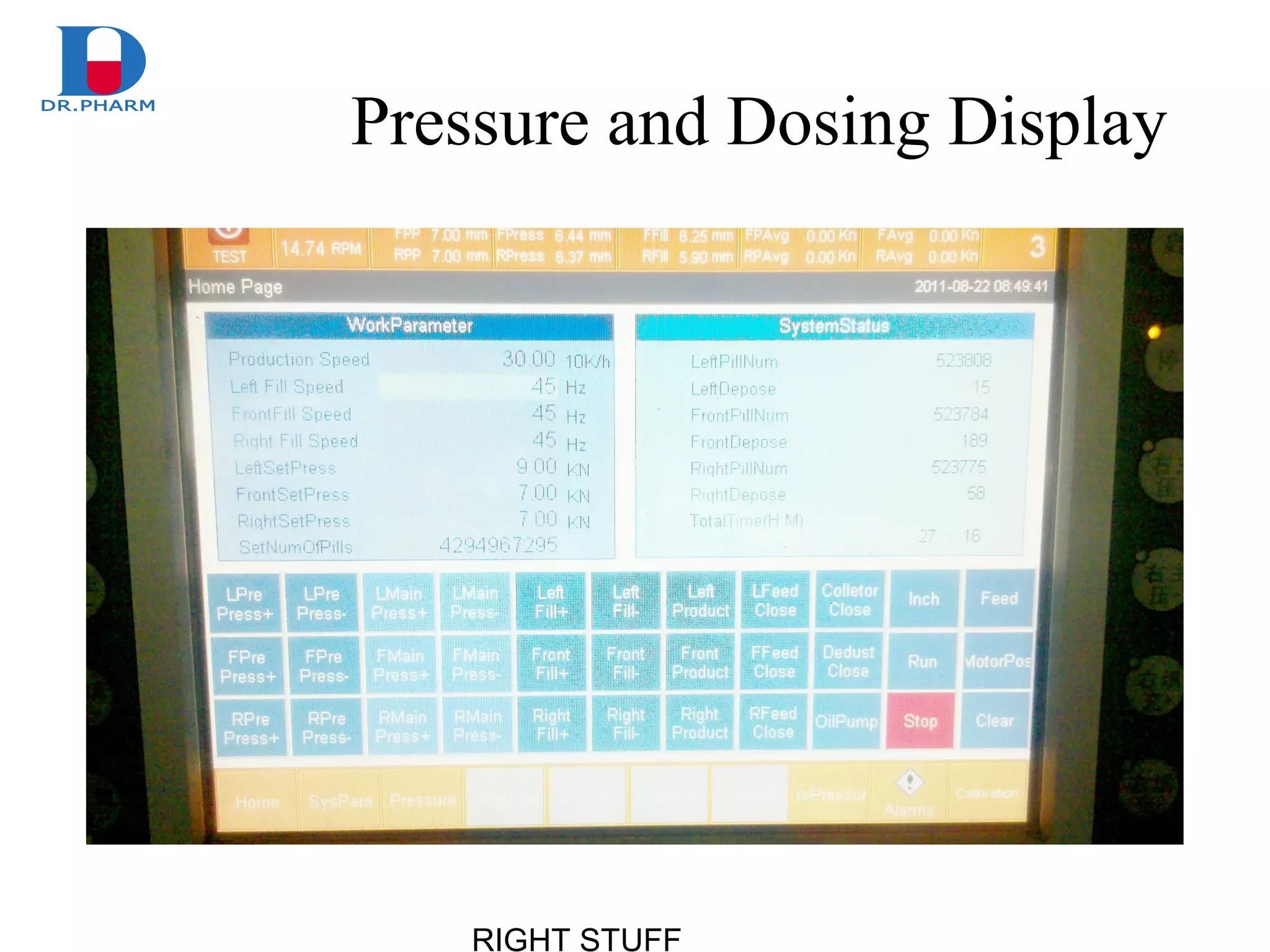

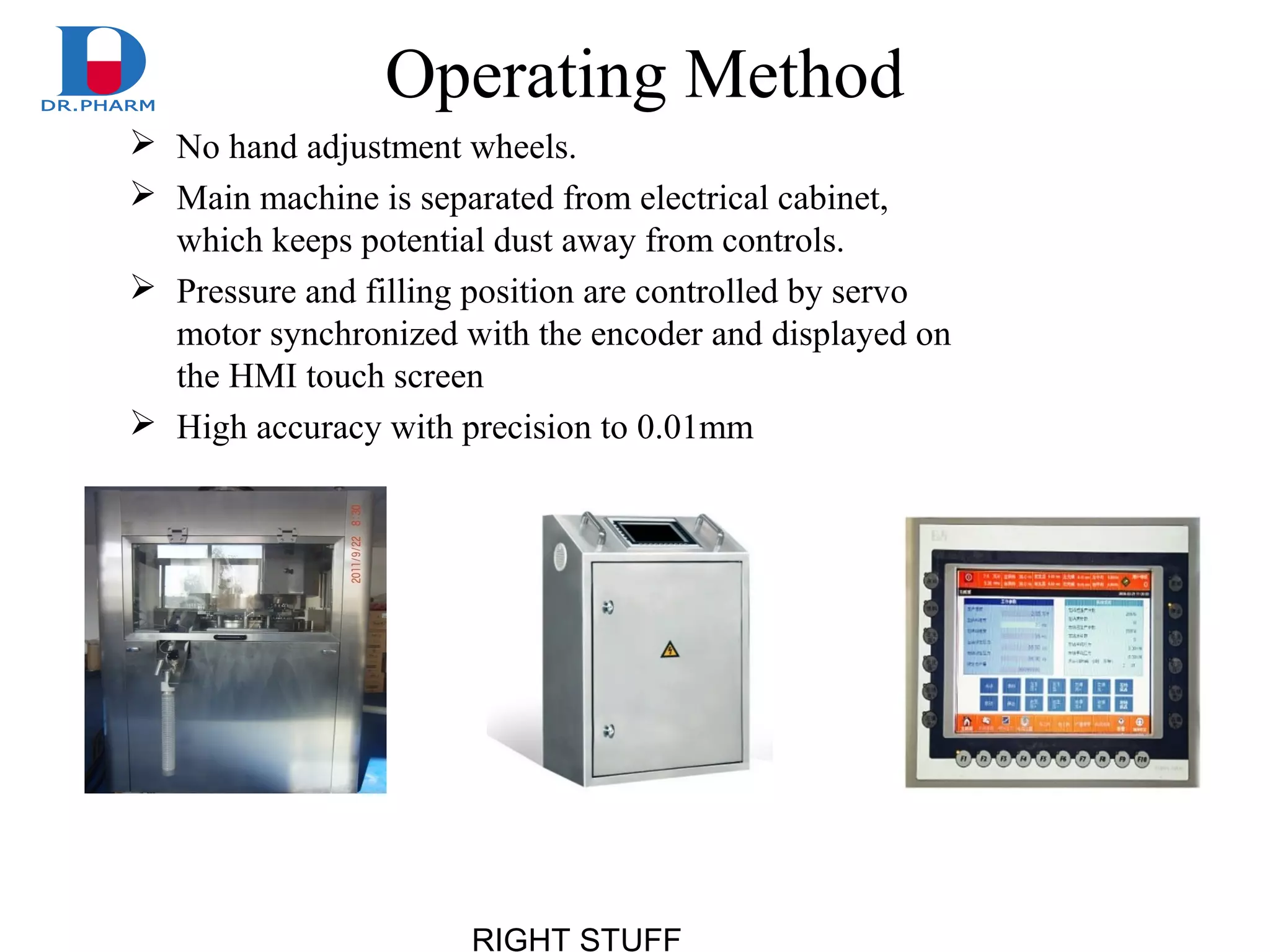

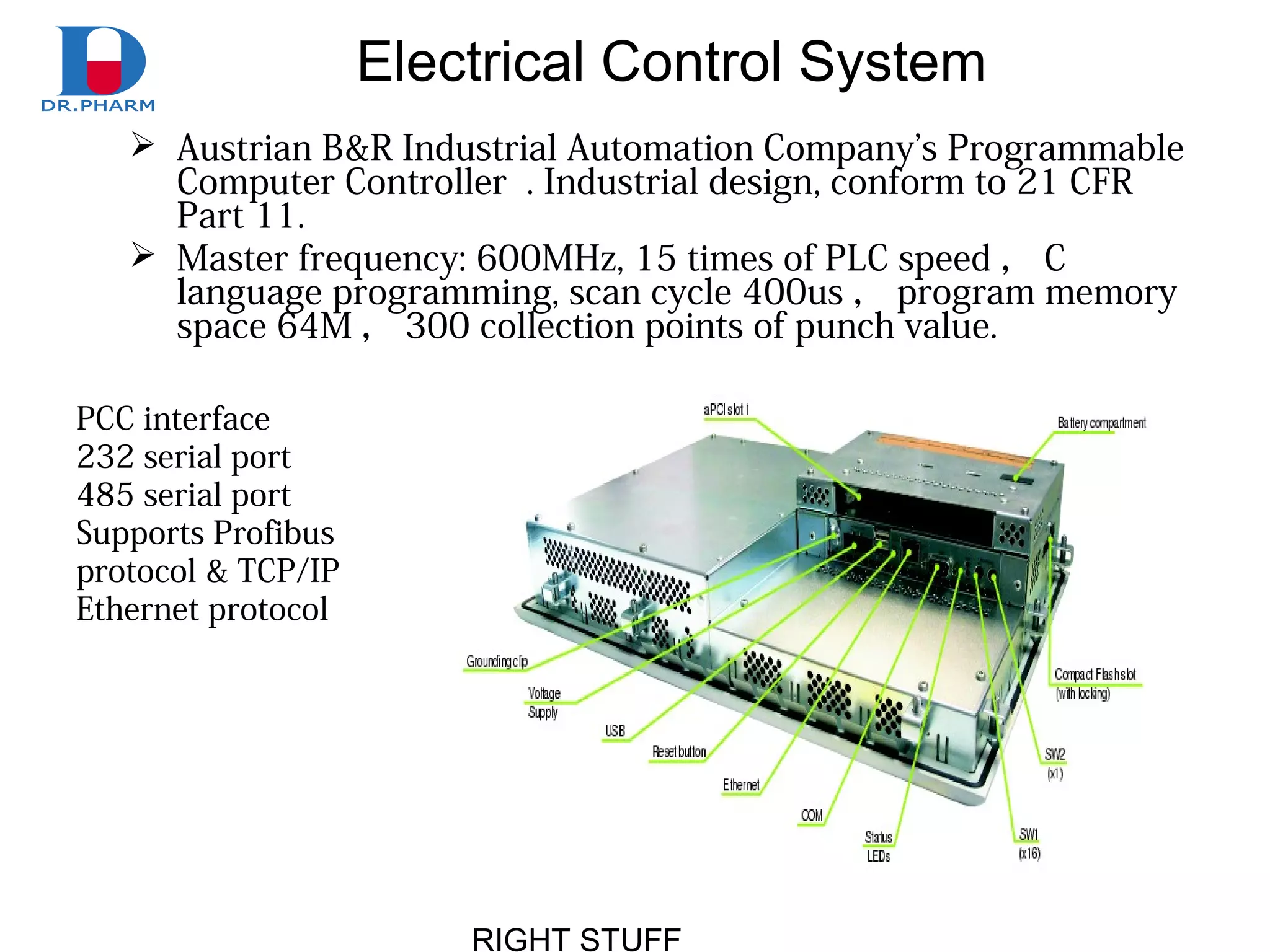

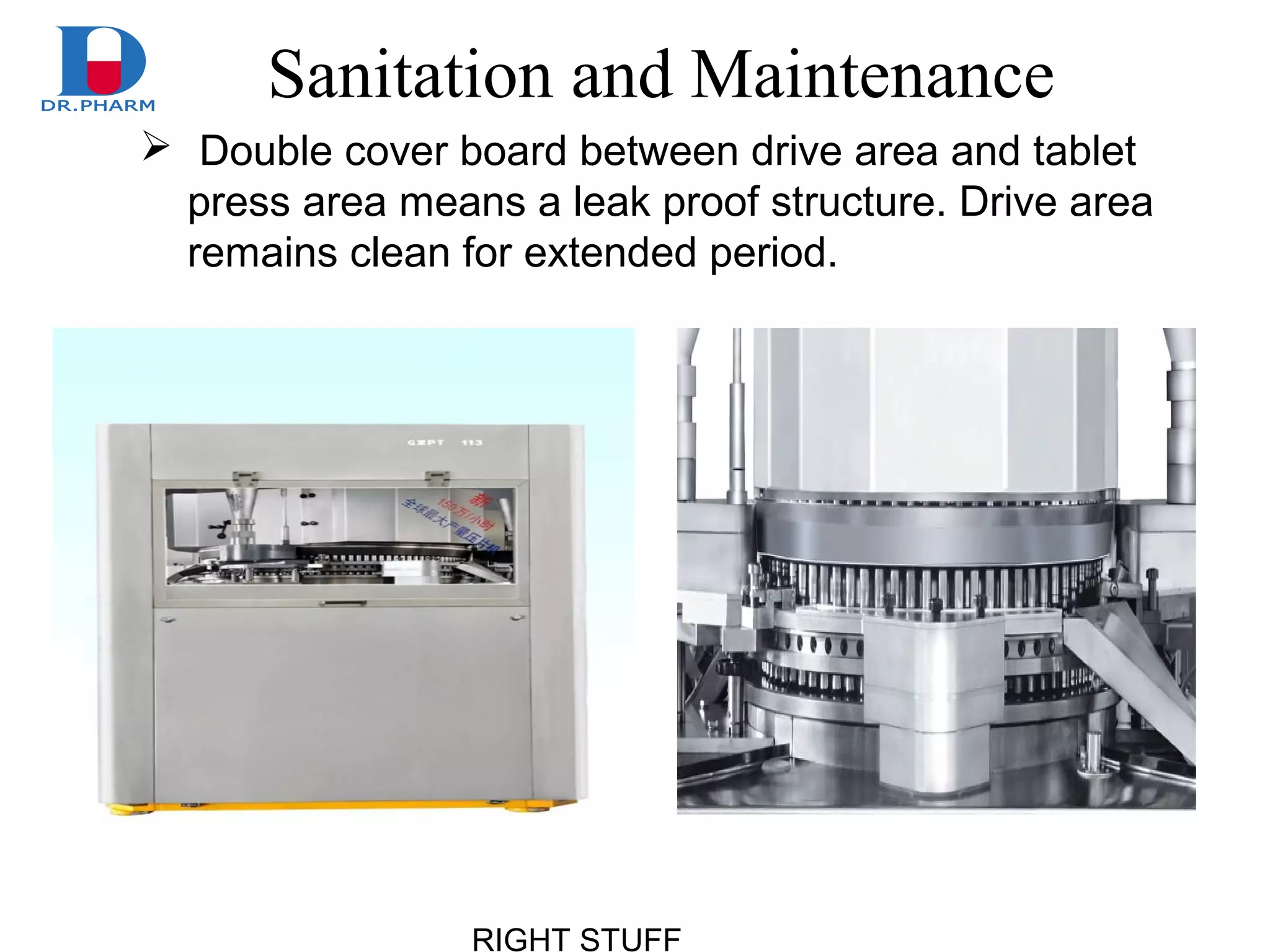

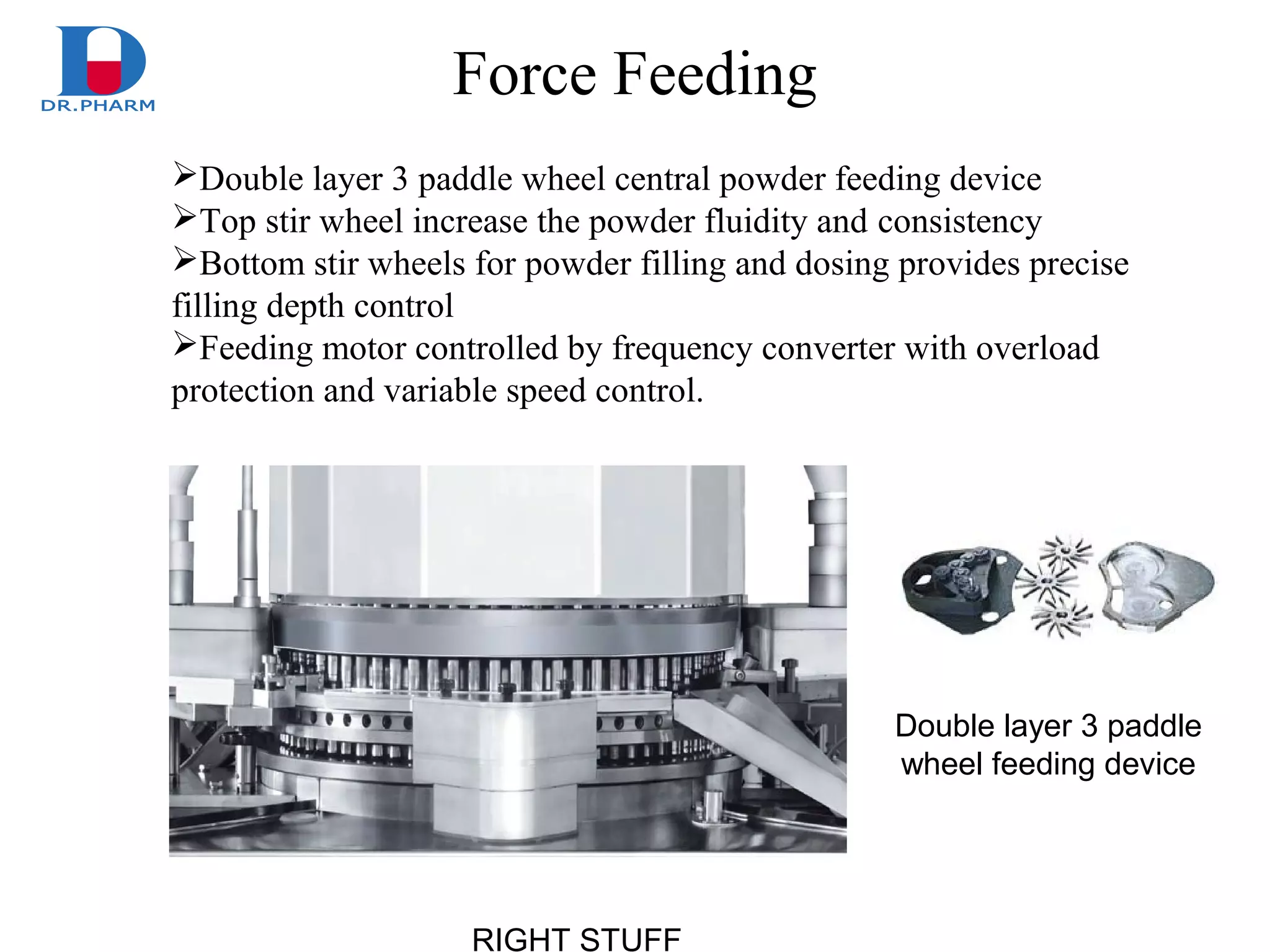

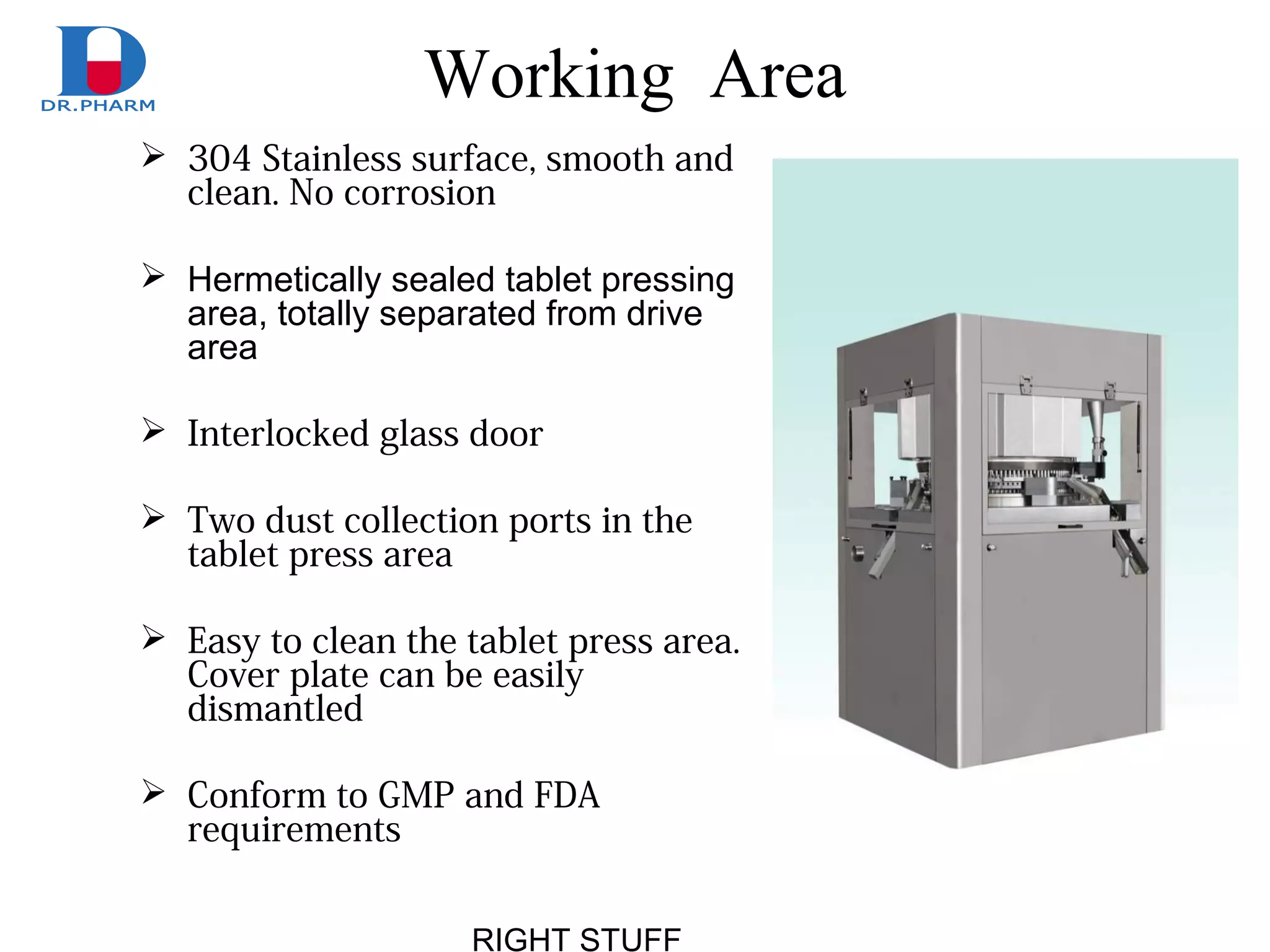

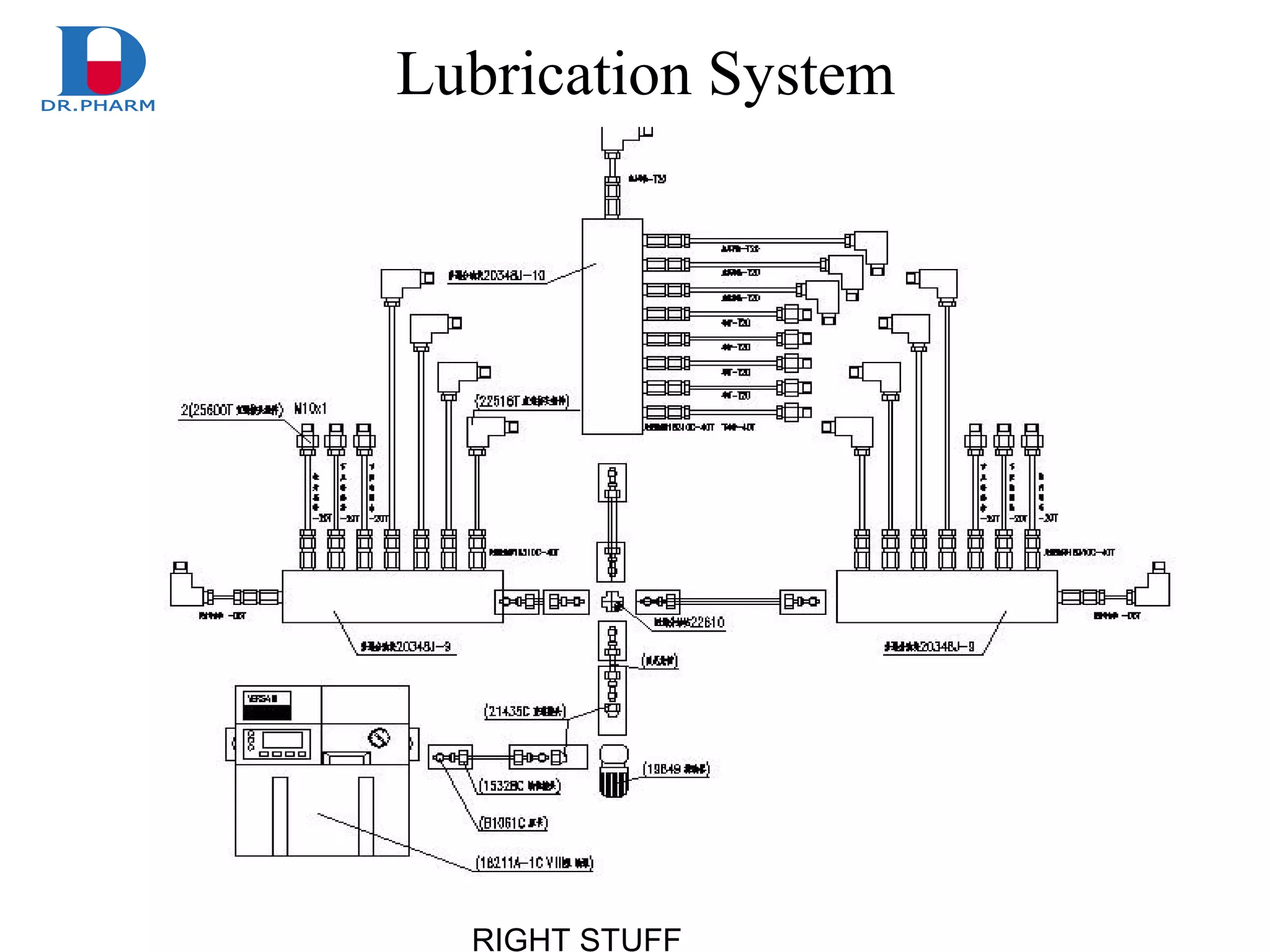

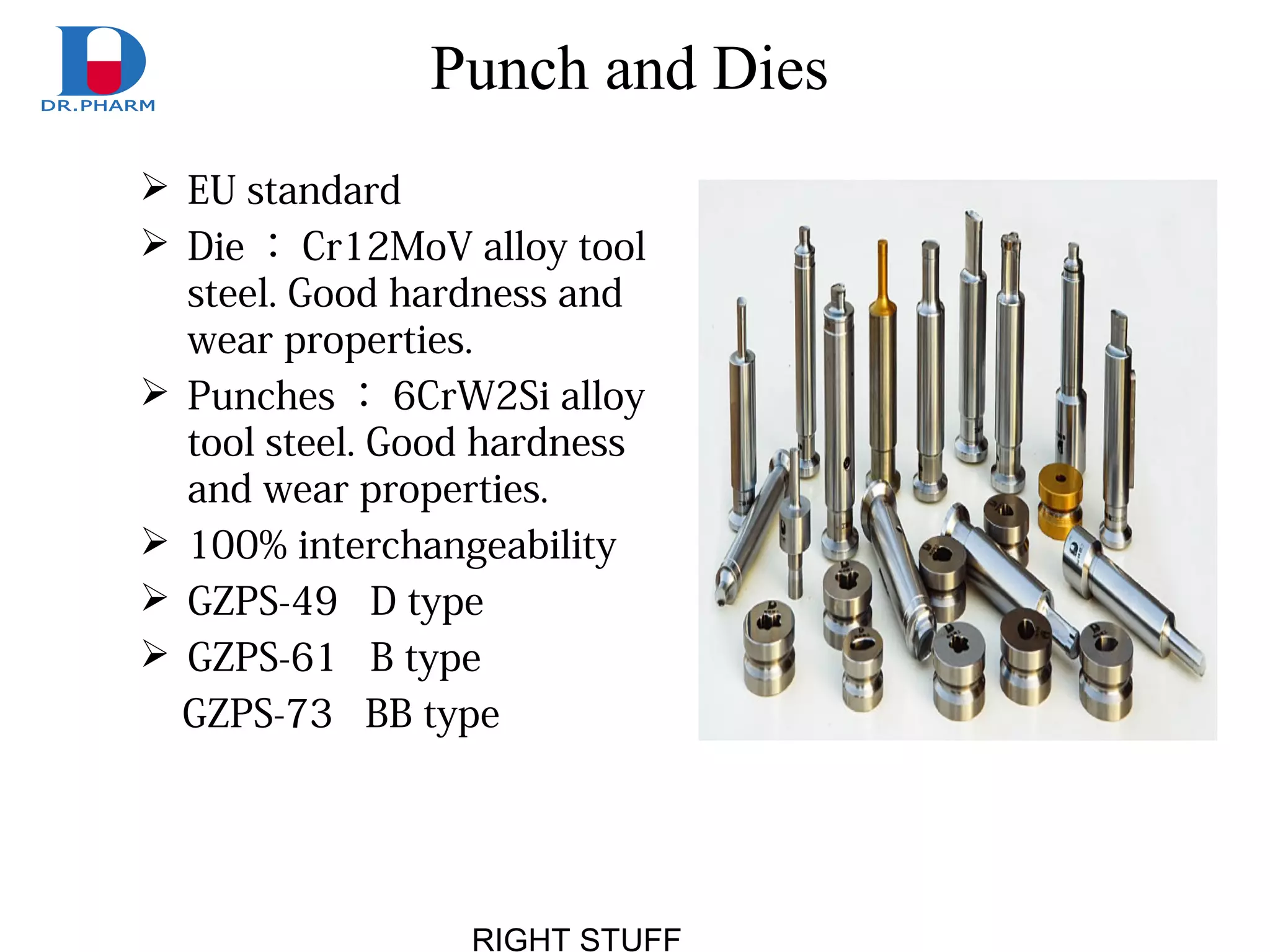

The document provides detailed specifications and features of the GZPS series high-speed rotary tablet press machines, which include automatic double discharge, various models, and multiple technical parameters such as output, motor power, and dimensions. It highlights essential features like the pre-pressure and main pressure systems, advanced pressure detection technology, sanitation and maintenance protocols, lubrication systems, and compliance with GMP standards. Additionally, it discusses the machine's design for easy operation, maintenance, and reliable production capabilities.