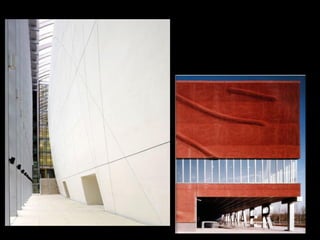

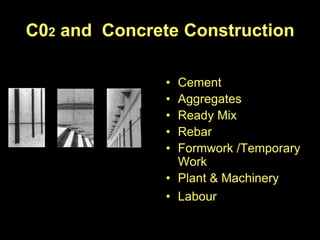

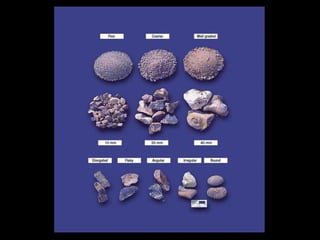

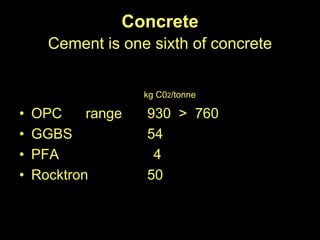

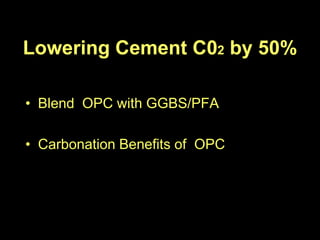

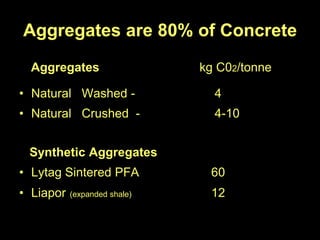

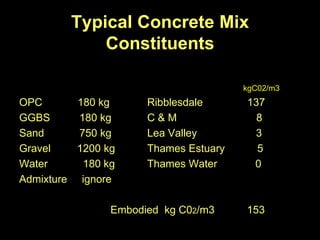

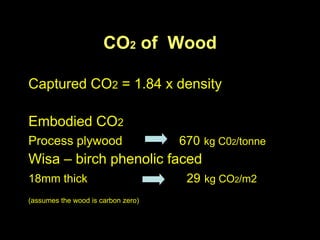

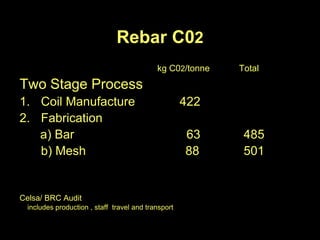

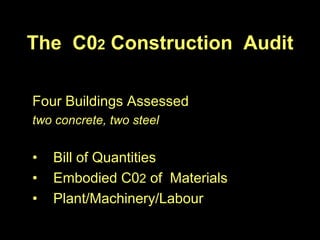

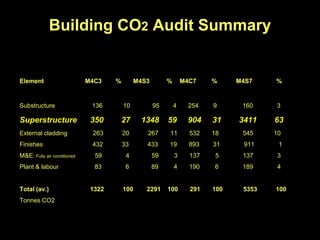

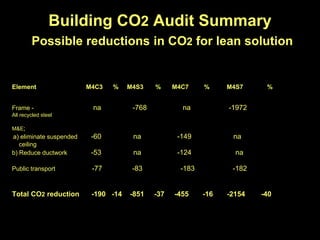

This document discusses strategies for reducing the carbon dioxide (CO2) emissions associated with concrete construction. It outlines various components of concrete mixes and their typical CO2 contributions. Lowering the cement content and replacing it with supplementary cementitious materials like ground granulated blast furnace slag (GGBS) or fly ash can reduce CO2 by 50%. Using natural aggregates rather than synthetic ones also lowers CO2. An audit process is presented for quantifying the embodied CO2 of different building materials and construction elements. With modifications like using recycled steel frames, less ductwork, and promoting public transport, construction CO2 can be reduced by up to 40%. The overall goal is to minimize CO2 through material selection and design solutions that also