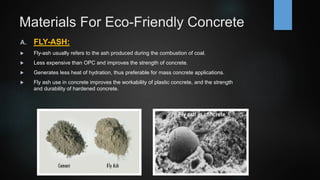

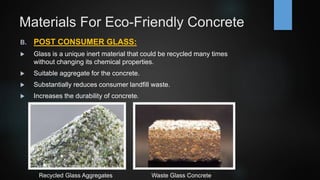

The document discusses eco-friendly or green concrete as concrete that uses less energy and produces less carbon dioxide than traditional concrete. It outlines various strategies for green concrete including increased use of recycled materials and supplementary cementitious materials. Specific materials that can be used in green concrete include fly ash, GGBS, silica fume, recycled concrete, glass, and plastic aggregates which provide benefits like reduced CO2 emissions and costs. The objectives and advantages of green concrete in sustainable construction are also presented.