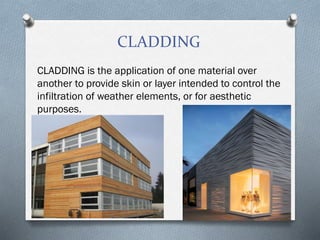

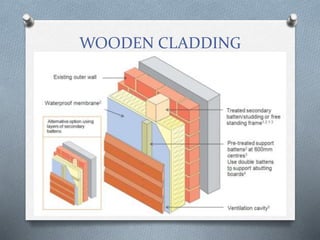

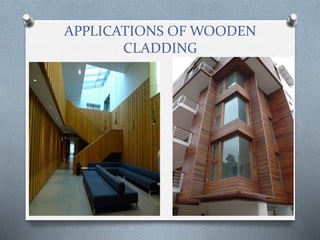

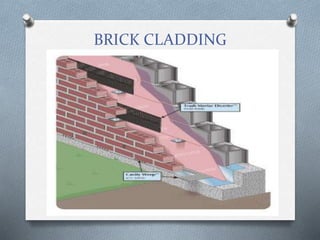

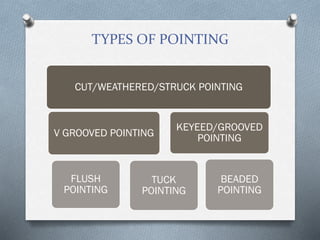

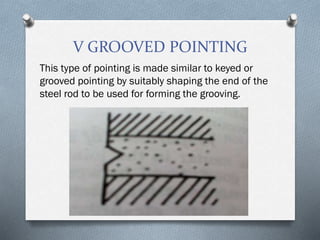

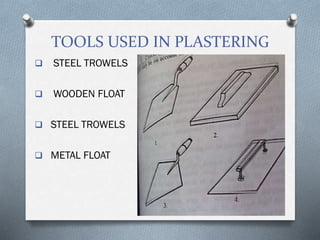

This document provides information on various building construction materials and techniques. It discusses surface finishes like plasters and paints that protect surfaces and provide decoration. It describes cladding materials like wood, stone, vinyl and metal that provide weather protection, aesthetics and insulation. It also details pointing and jointing techniques for brickwork and discusses plastering methods using materials like lime, cement and mud in single or multiple coats. Tools used for tasks like pointing, jointing and plastering are also outlined.