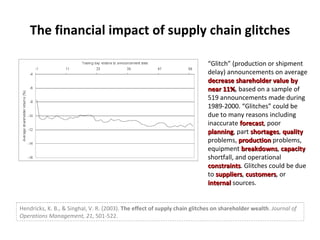

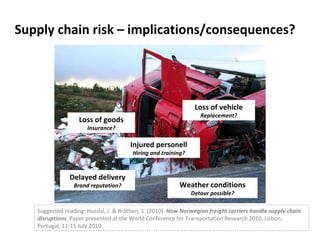

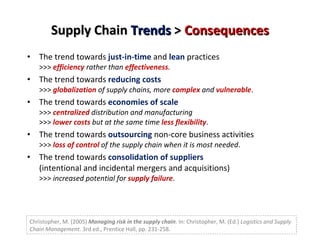

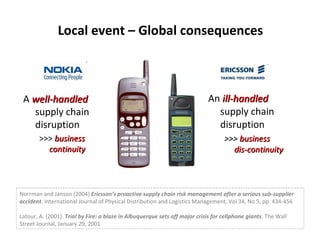

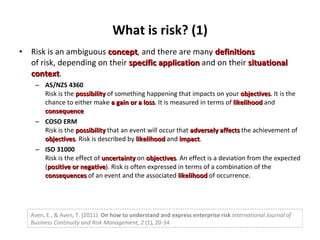

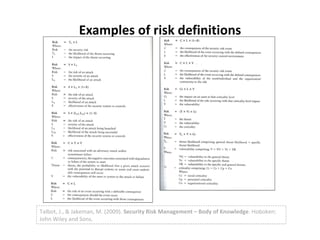

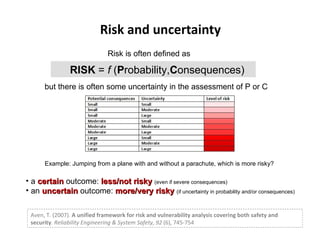

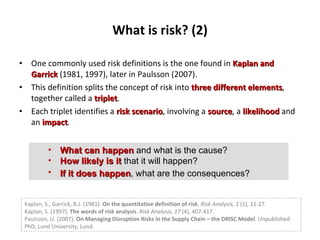

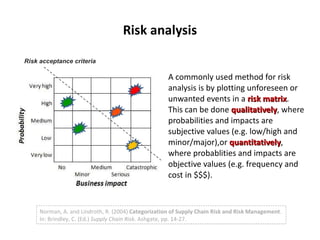

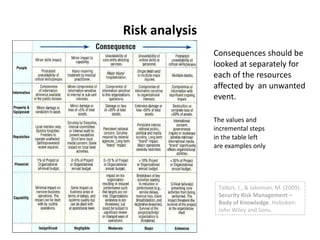

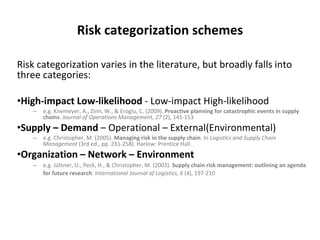

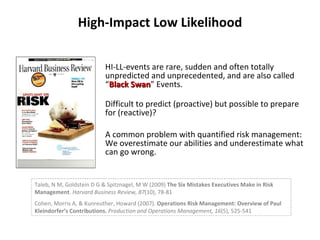

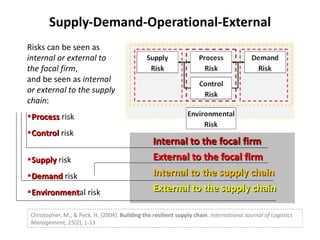

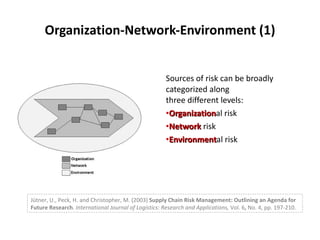

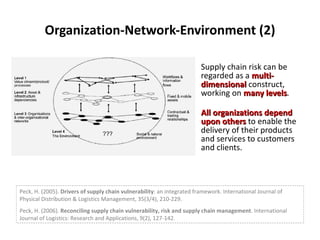

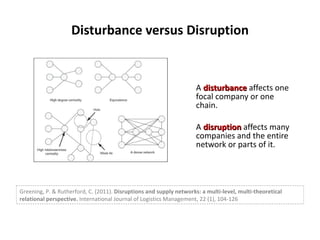

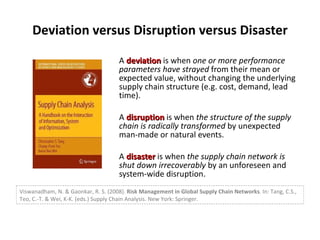

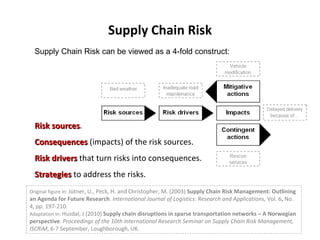

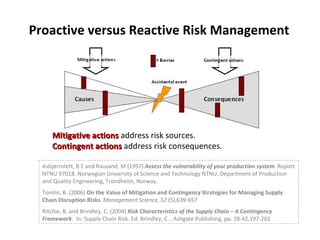

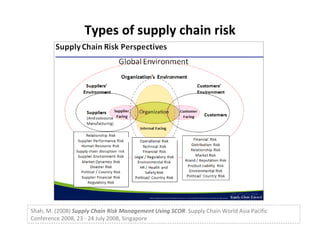

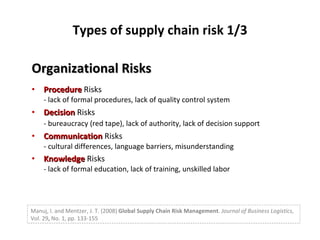

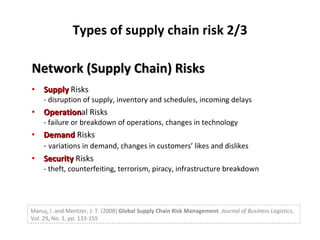

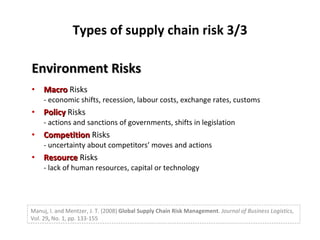

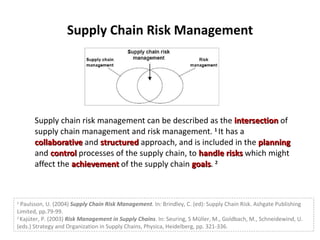

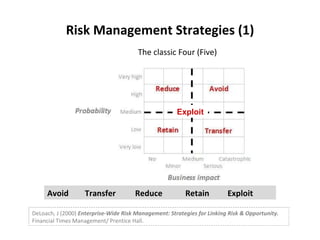

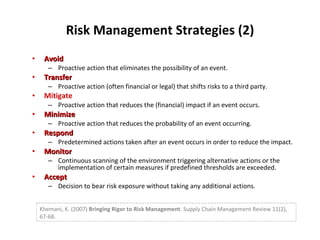

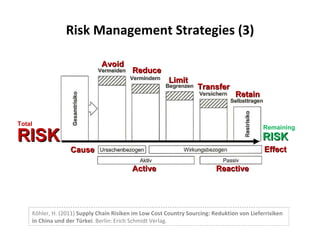

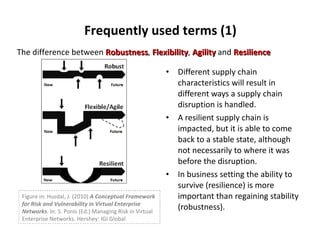

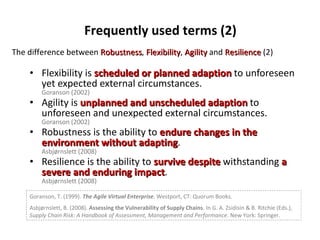

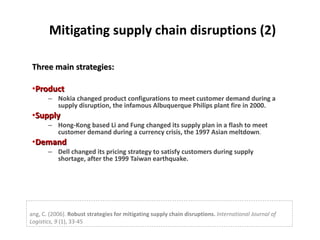

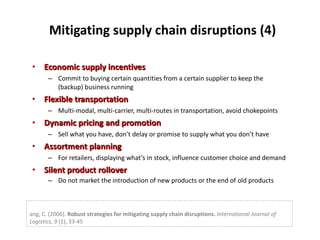

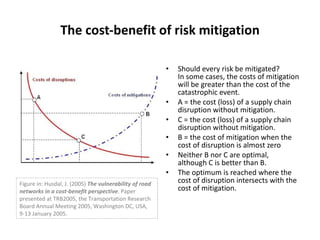

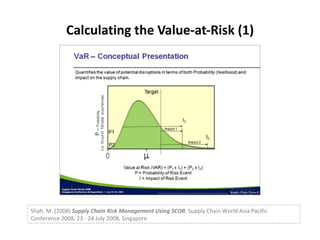

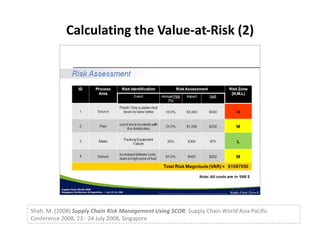

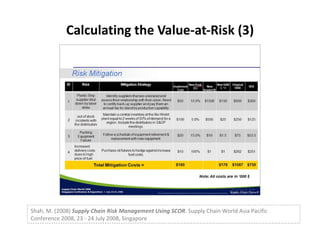

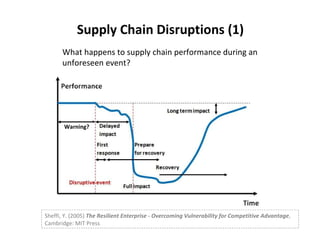

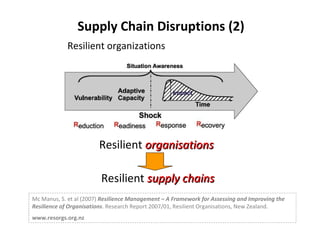

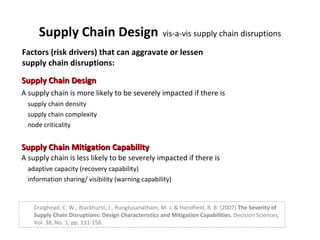

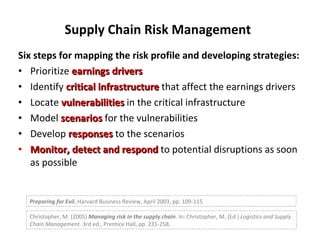

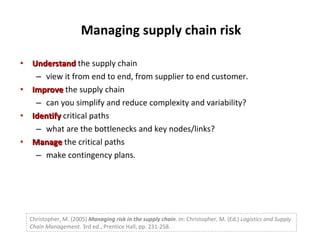

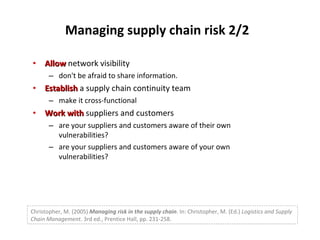

The document discusses supply chain risk management, highlighting the importance of understanding and mitigating risks related to disruptions, such as those caused by natural disasters and operational inefficiencies. It outlines various types of risks, their impacts on companies, and emphasizes the need for frameworks to manage these risks effectively. The lecture aims to provide a foundational understanding of supply chain risks and suggest resources for further reading.