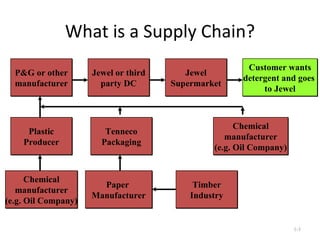

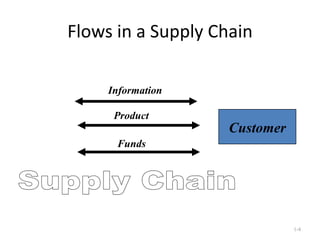

1. The document discusses supply chain management and defines a supply chain as all stages involved in fulfilling a customer request, including manufacturers, suppliers, transporters, warehouses, retailers, and customers.

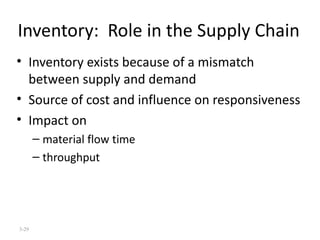

2. It explains that the objective of a supply chain is to maximize overall supply chain value created, which is the final product value minus total supply chain costs.

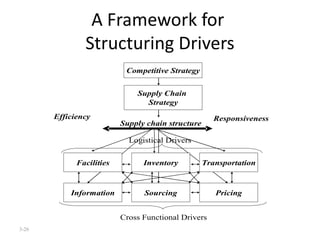

3. The document outlines the different decision phases in a supply chain: supply chain strategy and design, supply chain planning, and supply chain operations. It notes that strategy and design involve long-term strategic decisions while planning and operations have shorter time horizons.