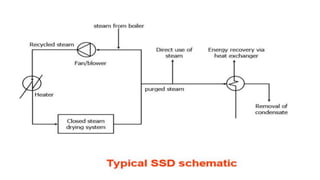

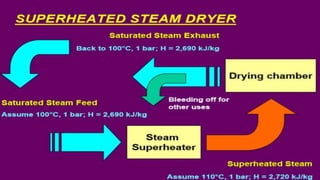

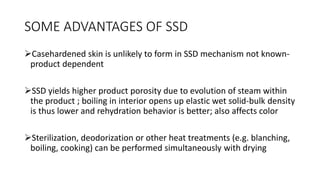

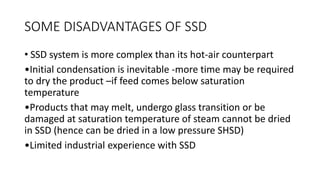

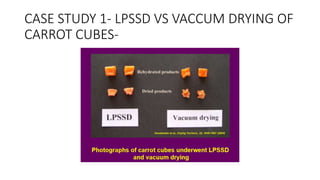

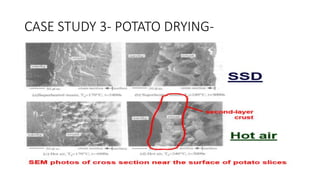

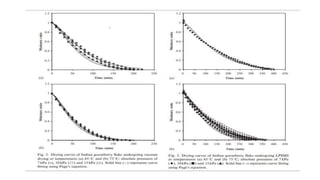

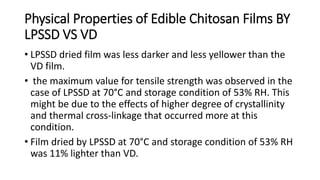

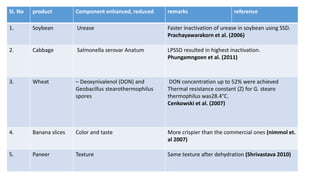

This document discusses superheated steam drying (SSD), providing an outline, introduction, principles, applications, and case studies. SSD uses superheated steam instead of hot air for drying. It can have lower energy use than hot air drying if steam is recovered. SSD results in better product quality in many cases due to lack of oxidation. Several case studies demonstrate SSD for drying foods like carrots, beet pulp, potatoes, gooseberries, and mangoes. Low-pressure SSD is suitable for drying heat-sensitive products.