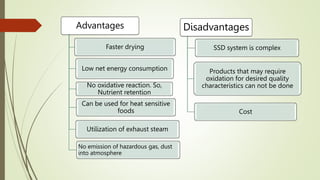

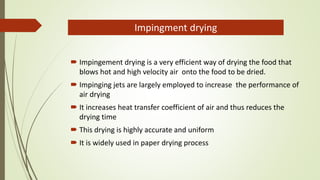

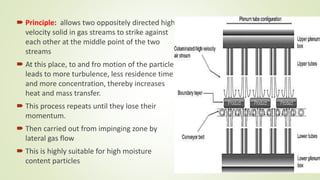

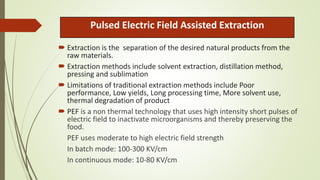

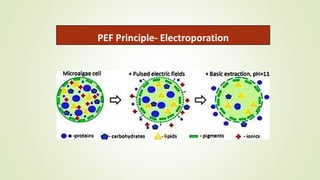

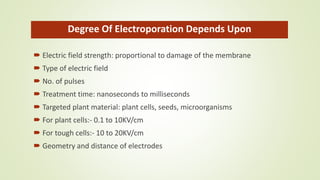

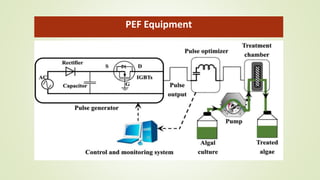

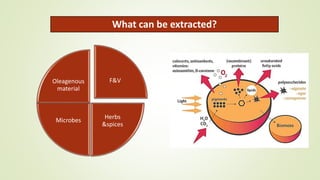

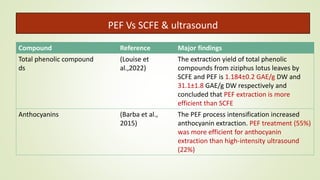

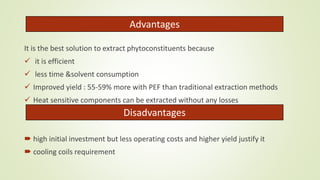

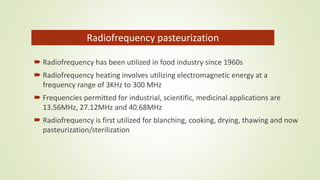

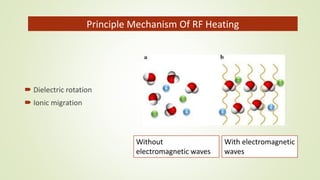

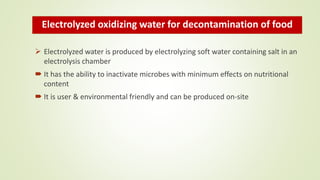

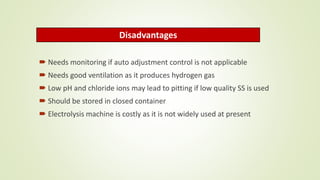

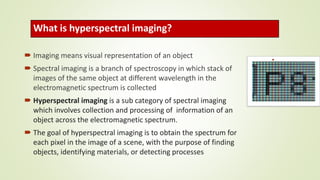

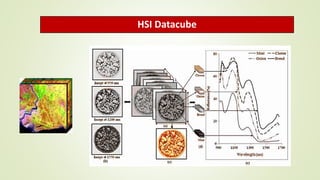

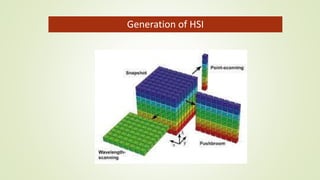

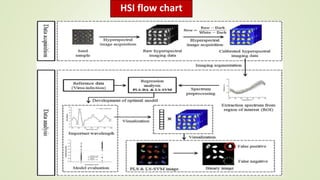

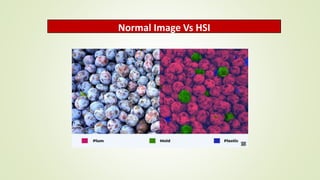

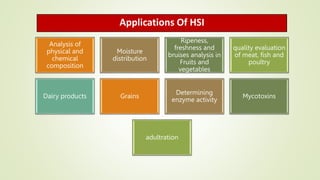

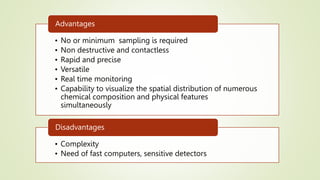

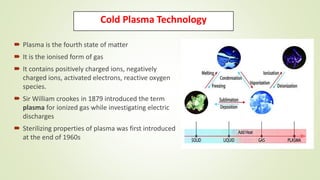

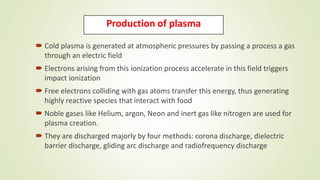

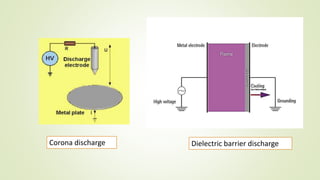

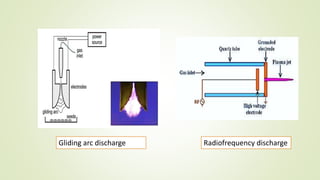

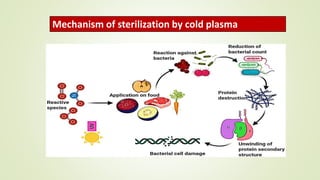

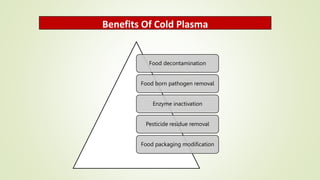

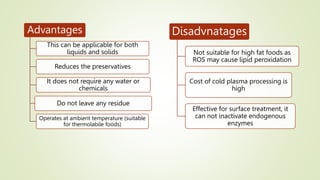

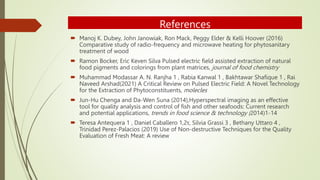

The document outlines recent advances in food engineering focusing on innovative drying techniques, extraction methods like pulsed electric field (PEF), and the use of technologies such as cold plasma and hyperspectral imaging. It discusses how these advancements improve food quality, enhance energy efficiency, and streamline processing methods, highlighting both their advantages and limitations. The content serves as a master seminar presentation submitted for academic evaluation at a food technology college.