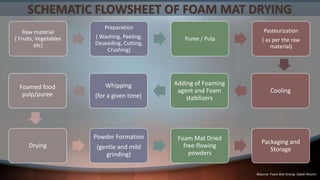

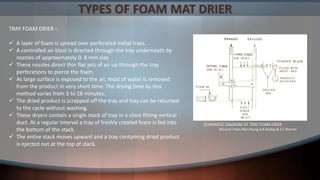

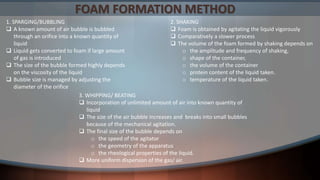

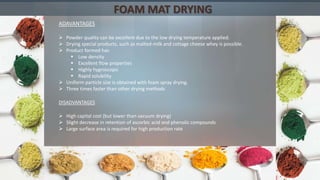

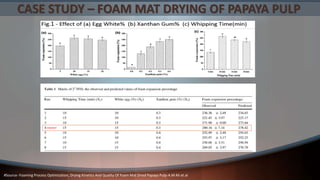

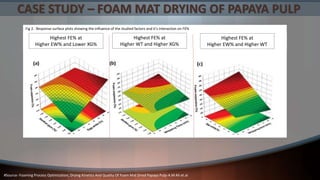

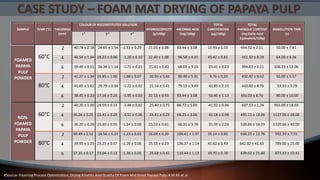

The document discusses foam-mat drying, a technique for dehydrating heat-sensitive materials, which preserves their color, flavor, and nutrients. It operates in four steps: preparation, foam formation, drying, and product evaluation, highlighting various drier types and their mechanisms. Additionally, a case study on the foam mat drying of papaya pulp is presented, illustrating the optimal conditions and resulting product characteristics.