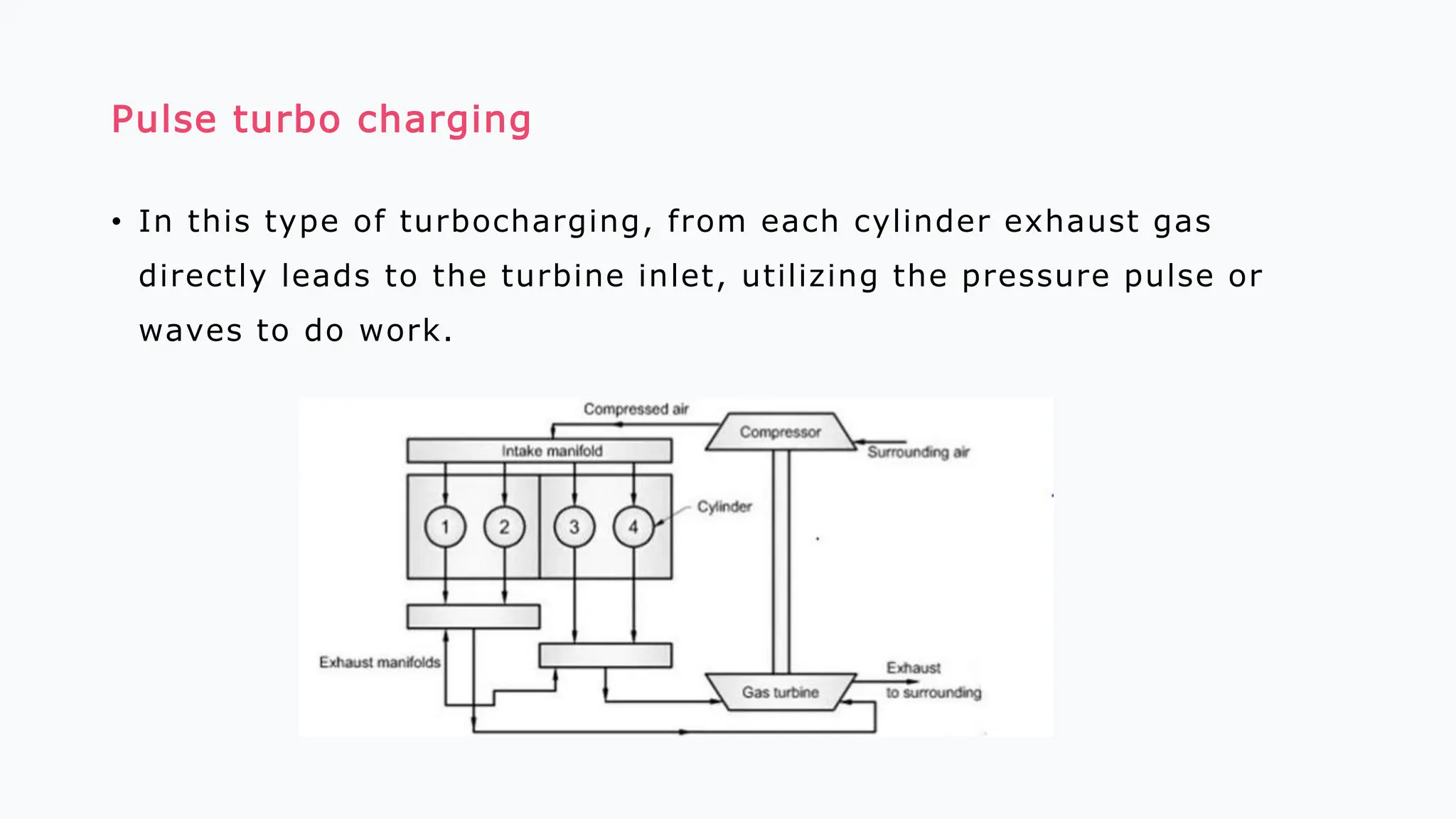

The document discusses supercharging and turbocharging, highlighting the need for increased power output and reduced emissions in engine design. It details the effects, types, and methods of supercharging, including its benefits such as improved volumetric efficiency and fuel consumption. Additionally, it covers turbocharging techniques, emphasizing the advantages of different methods like constant pressure and pulse turbocharging.

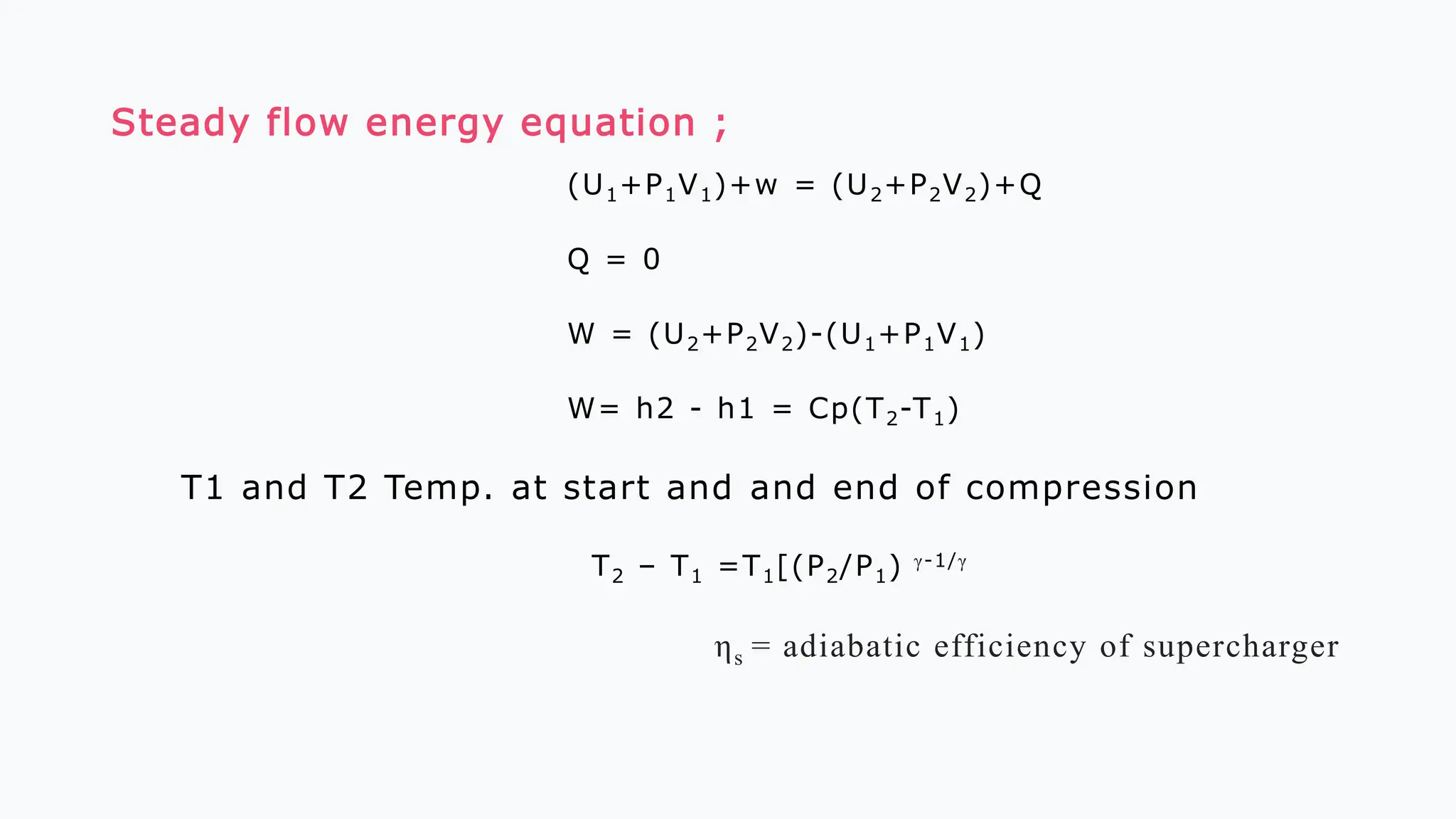

![Workdone / kg of air :

W = Cp(T2-T1)

W = CpT1[(P2/P1)

γ-1/γ -1 ] ×1/ ηS

Power required to drive the supercharger;

P = ma

W = maCpT1[(p2/p1) γ-1/γ -1 ] ×1/ ηs

ma is the amount of air /second supplied by the supercharger](https://image.slidesharecdn.com/superchargingandturbochargingppt17lastone1-231027120034-ab5f0e4e/75/Supercharging_and_Turbocharging_PPT_17_last_one-1-pptx-13-2048.jpg)