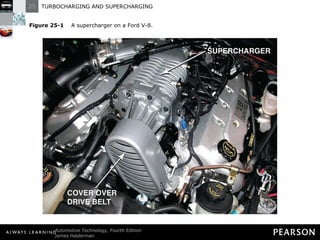

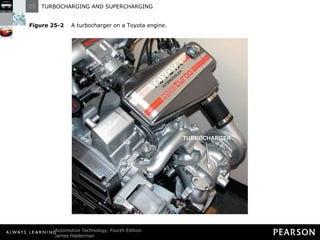

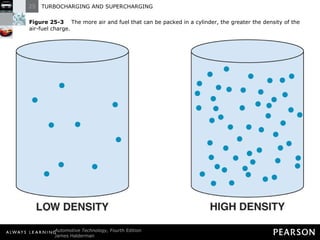

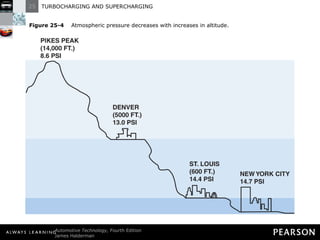

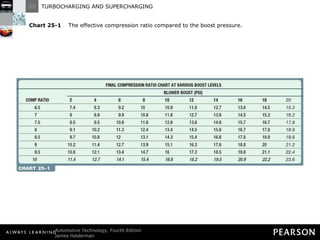

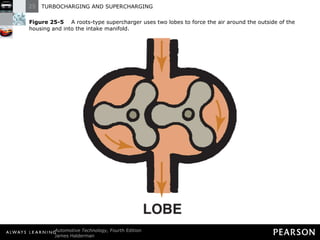

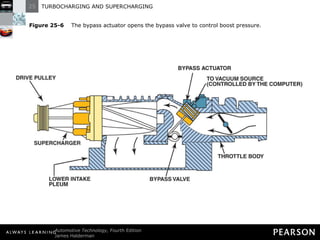

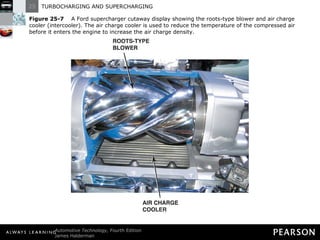

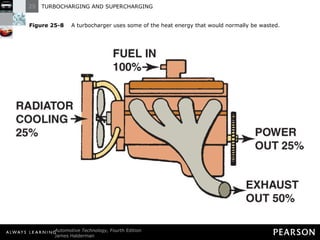

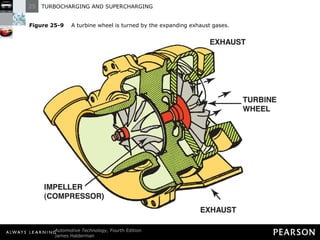

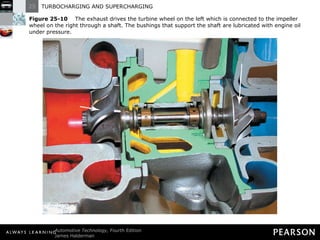

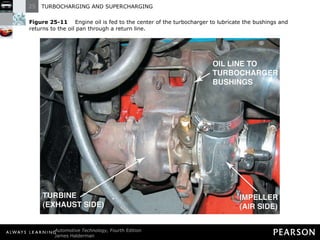

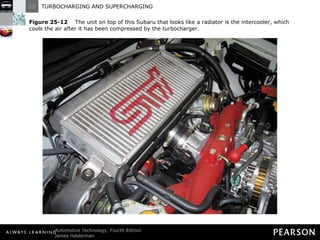

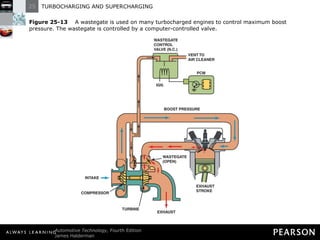

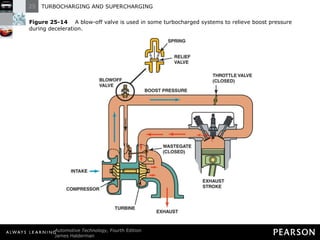

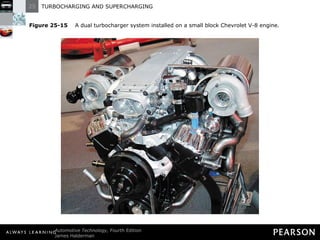

The document provides information about turbocharging and supercharging engines. It explains that turbochargers and superchargers work by forcing more air into the engine cylinders to increase power. A turbocharger uses exhaust gases to power a turbine, which drives an air compressor, while a supercharger is driven directly by the engine. The document describes the different types of superchargers and turbochargers, and discusses how boost pressure is controlled and maintenance procedures for forced induction systems.