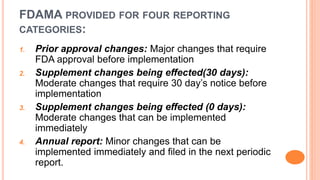

The document discusses scale up and post approval changes (SUPAC) for generic drug applications. It defines SUPAC as changes made to a drug's composition, manufacturing process, equipment, or site after approval. The FDA modernization act of 1997 established four categories for reporting post-approval changes - prior approval, 30-day notice, immediate implementation, and annual report. The FDA has issued SUPAC guidance documents that describe what types of changes require validation studies or prior approval versus those allowable without notice. Post-marketing surveillance is also required to monitor adverse drug events after approval.