Phase change materials (PCMs) can store and release large amounts of heat energy as they change phase between solid and liquid states. There are three main types of thermal energy storage: sensible heat, latent heat, and thermochemical heat. Latent heat storage uses PCMs, which absorb or release heat during phase changes without changing temperature. Common PCMs include salt hydrates, paraffin waxes, and fatty acids. PCMs can be encapsulated in small spheres or other shapes to improve heat transfer properties and prevent leakage. Encapsulated PCMs have applications in building insulation, solar energy storage, textiles, and more.

![Phase Change Material

Phase change method[1]

1) Higher thermal storage capacity compared to sensible energy storage in water. This leads to

smaller required storage. Only a true advantage if only small useful temperature difference can

be achieved.

2) Relatively constant temperature during charging and discharging

3) Burner cycle for the backup generation unit and therefore their CO and HC emission can be

reduced.](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-3-320.jpg)

![Phase Change Material

Properties of PCM[2]

1) Melting point should be in the desired temperature range.

2) High latent heat of fusion per unit volume to store more energy in a given volume.

3) High thermal conductivity to assist charging and discharging of energy.

4) Low changes in volume during phase change and low vapor pressure to avoid

containment problems.

5) Non-flammable and non-toxic.

6) Chemically stable.

7) Low cost and low containment cost.

8) Low vapor pressure (<1 bar) at the operational temperature.](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-4-320.jpg)

![Phase Change Material

Phase change material[3]](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-5-320.jpg)

![Phase Change Material

Inorganic Material[3]

1) Salt Hydrate:

It may be regarded as alloy of inorganic salt and water forming a typical crystalline solid of general formula

AB.nH2O

AB.nH2O=AB.mH2O + (n-m)H2O

Example: Water of Crystallization

CuO + H2SO4 = CuSO4 + H2O

(CuSo4.5H2o) Hydrated salt

5.H2O= Water of Crystallization

A salt hydrate usually melts to either to a salt hydrate with fewer moles of water.](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-6-320.jpg)

![Overview about Organic Materials

Organic Materials

• possess the ability to absorb and release the large quantity of latent

heat during phase change process over a certain temperature range

• are naturally existing petroleum bi-products such as naphtha,

gasoline, fuel oil, bitumen, and hexane [3].

• have their unique phase change temperature

• generally have the temperature range between -70 C to 250 C

• undergo solid-liquid, solid-solid phase transition during heating and

cooling processes [3]

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-9-320.jpg)

![Temperature effect [18]

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-10-320.jpg)

![Classification of Organic Materials [18]

(a) Paraffin Materials (b) Non-paraffin Materials

Paraffin wax Rubi-therm Dry granules

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-11-320.jpg)

![Paraffin Materials

• It consists of a mixture of mostly straight chain n- alkanes CH3–

(CH2)–CH3.

• The crystallization of a CH3 chain release a large amount of latent

heat.

• However, under cost consideration, only technical grade paraffin may

be used in latent heat storage systems.

Paraffin Freezing range(C) Heat of Fusion (KJ/KG)[3]

6106 42 – 44 189

5838 48 – 50 189

6035 58 – 60 189

6499 66 – 68 189

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-12-320.jpg)

![• The materials have phase change temperature below 15 C are used in

cooling cycles while the materials who have above 90 C phase change

temperature are used in absorption refrigeration cycles.

• Moreover, PCMs having in between 15 C to 90 C are used in heating

cycles.

• Paraffin is safe, reliable, non corrosive, and less expensive material.

• Some undesirable properties are [3] :

(i) Low thermal conductivity

(ii) Non compatible with plastic container

(iii) Flammable

• Above three effects can be partially eliminated by modifying the wax

and the storage system.

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-13-320.jpg)

![Non-Paraffin Materials

• They are different from the paraffin materials because all the

materials have unique properties.

• They should not be exposed to excessively high temperature.

• Properties [3] :-

(i) high heat of fusion

(ii) varying level of toxicity

(iii) instability at high temperature

(iv) mild corrosive

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-14-320.jpg)

![Phase Change Material

Phase diagram of eutectic mixture[5] [6]

Ta1

L1 composition

Ta2

Ta3

Ta4

Proeutectic α

Liquid

Proeutectic α

Proeutectic α

eutectic β

eutectic α

Liquid](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-15-320.jpg)

![Phase Change Material

Phase diagram of eutectic composition[5]

Ta2](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-17-320.jpg)

![Phase Change Material

Eutectic materials[3]](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-19-320.jpg)

![Phase Change Material

Eutectic mixture of Galactitol and Mannitol[4]](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-20-320.jpg)

![Phase Change Material

Phase diagram of Galactitol and Mannitol [4]

Eutectic composition 30:70 G/M

Melting Temperature:153◦ C

Heat of fusion: 292 J.g-1](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-21-320.jpg)

![Applications of PCM[7]

• Latent heat battery

• Heating in buildings

• Solar water heater

• Cold storage and sports ware

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-23-320.jpg)

![Latent heat battery[7]

• Stores the heat from radiator of car.

• The stored heat is utilized to warm up the engine during cold start.

• It can store energy for 2 days.

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-24-320.jpg)

![Heating in building[8]

• Heating:

• PCM mats are used on the roof and walls of

the building.

• It absorbs the heat during sunshine hours and

melts.

• The liquid PCM freezes during night and

releases the heat in the building.

Phase Change Material

(Source:phasechangeenergy.com) [4.2]](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-25-320.jpg)

![Solar water heater[9]

• Water is heated during sunshine hours.

• Hot water transfers heat to the PCM.

• Hot water is replaced by cold water during

night which gets heat from the liquid PCM.

Phase Change Material

Solar water heater[4.5]](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-26-320.jpg)

![• Sports ware:[10]

• PCM maintains balance between heat generated from body

and heat released to the environment.

• It reduces thermal stress.

• Cold storage:[10]

• PCM can be used in refrigerator as a backup in case of power

failure.

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-27-320.jpg)

![Advantages of PCM:[12]

• Wide melting point range from -40 C to 151 C.

• Stable for more cycles.

• Service life is high.

• High latent heat.

• Non-toxic

• Cost depends on the purity of material( From 1.5$/lb to 24$/lb)

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-28-320.jpg)

![Disadvantages:[13]

• Flammable

• Low volumetric latent storage heat capacity

• Low heat transfer rate in solid state

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-29-320.jpg)

![PCM Encapsulation

Phase Change Material

[14]](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-31-320.jpg)

![Scaling Of Forces [15]

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-33-320.jpg)

![MPCM In Building [16]

PCM Encapsulation](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-35-320.jpg)

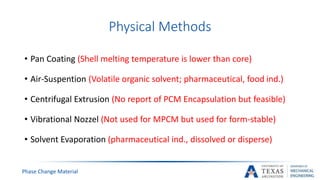

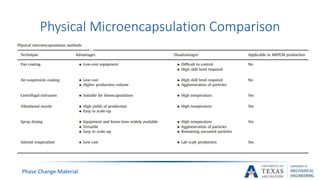

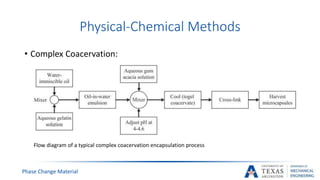

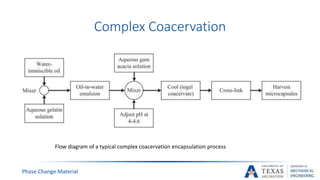

![PCM Encapsulation Manufacturing [17]

Pan coating

Air-Suspension

Centrifugal Extrusion

Vibrational Nozzle

Spray Dying

Solvent Evaporation

Physical

Methods

Ionic Gelation

Coacervation

Sol-GEl

Physic-

Chemical

methods

Ionic Polymerization

Suspension

Polymerization

Emulsion

Polymerization

Chemical

Methods

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-38-320.jpg)

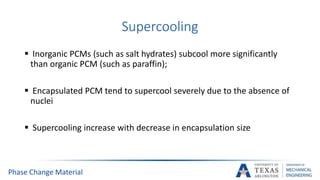

![Supercooling phenomenon [17]

• Supercooling is a state where liquids solidify below their normal

freezing point

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-51-320.jpg)

![References

[1] Gupta, E. & Reinhart, N. (n.d.). RGEES LLC innovating sustainable thermal

comfort. Retrieved from http://www.rgees.com/about.php

[2] Mishra, A., Shukla, A. & Sharma, A. (June 2015). Latent heat storage

through phase change material.

[3] Sharma, A., Tyagi, V. V., Chen, C. R., & Buddhi, D. (2009). Review on

thermal energy storage with phase change materials and

applications. Energy Renewable and Sustainable Reviews, 13(2), 318-

345. doi:10.1016/j.rser.2007.10.005

[4]Paul, A., Shi, L., & Bielawski, C. (2015). A eutectic mixture of galactitol and

mannitol as a phase change material for latent heat storage. Energy

Conversion and Management, 103, 139-146.

doi:10.1016/j.enconman.2015.06.013](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-57-320.jpg)

![[5] Imre, B. (2007).Eutectic system phase diagram. Retrieved from

https://en.wikipedia.org/wiki/Eutectic_system#/media/File:Eute

ctic_system_phase_diagram.svg

[6] Best,B.,(n.d.). Lessons for Cryonics from Metallurgy and Ceramics

Retrived from http://www.benbest.com/cryonics/lessons.html

[7] Phase change material pcm manufacturers,applications and

uses, Retrieved from

http://www.teappcm.com/applications.htm

[8] Muruganantham. K. Applications of phase change material in

building: field data vs. energy plus simulation, (2010).

[9] Kitano, H., Sagara, K., Sharma, S.D, Phase change materials for

low temperature solar thermal applications,(2004),p.31-64.

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-58-320.jpg)

![[10] Arjun, D., Hayavadana,J., Thermal energy storage materials

(PCMs) for textile applications,Volume 8,Issue 4

[11] J. Prakash, H. P. Garg, G.Datta,A solar water heater with a

built-in latent heat storage, Energy conversion and

management 25 (1985) 51-56.

[12] Phase change materials, retrieved from

http://www.puretemp.com/stories/understanding-pcms

[13] Phase change materials,retrieved from

https://en.wikipedia.org/wiki/Phase-

change_material#Organic_PCMs

[14] Tyagi, V. V., et al. "Development of phase change materials

based microencapsulated technology for buildings: a

review." Renewable and Sustainable Energy Reviews 15.2

(2011): 1373-1391.

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-59-320.jpg)

![[15] Fearing, Ronald S. "Survey of sticking effects for micro parts

handling."Intelligent Robots and Systems 95.'Human Robot

Interaction and Cooperative Robots', Proceedings. 1995 IEEE/RSJ

International Conference on. Vol. 2. IEEE, 1995.

[16] Jamekhorshid, A., S. M. Sadrameli, and M. Farid. "A review of

microencapsulation methods of phase change materials (PCMs) as a

thermal energy storage (TES) medium." Renewable and Sustainable

Energy Reviews31 (2014): 531-542.

[17] Al-Shannaq, Refat, et al. "Supercooling elimination of phase change

materials (PCMs) microcapsules." Energy 87 (2015): 654-662.

[18] Sutterlin, W. R. (2011). Introduction to thermal energy storage. The

Journal of Pharmaceutical and Biopharmaceutical Contract

Services. Retrieved from

http://www.pharmoutsourcing.com/Featured-Articles/37854-Phase-

Change-Materials-A-Brief-Comparison-of-Ice-Packs-Salts-

Paraffins-and- Vegetable-derived-Phase-Change-Materials/

Phase Change Material](https://image.slidesharecdn.com/655aff94-3c38-4d16-932e-6ba2144931fd-160207193218/85/Submitted-Presentation-60-320.jpg)