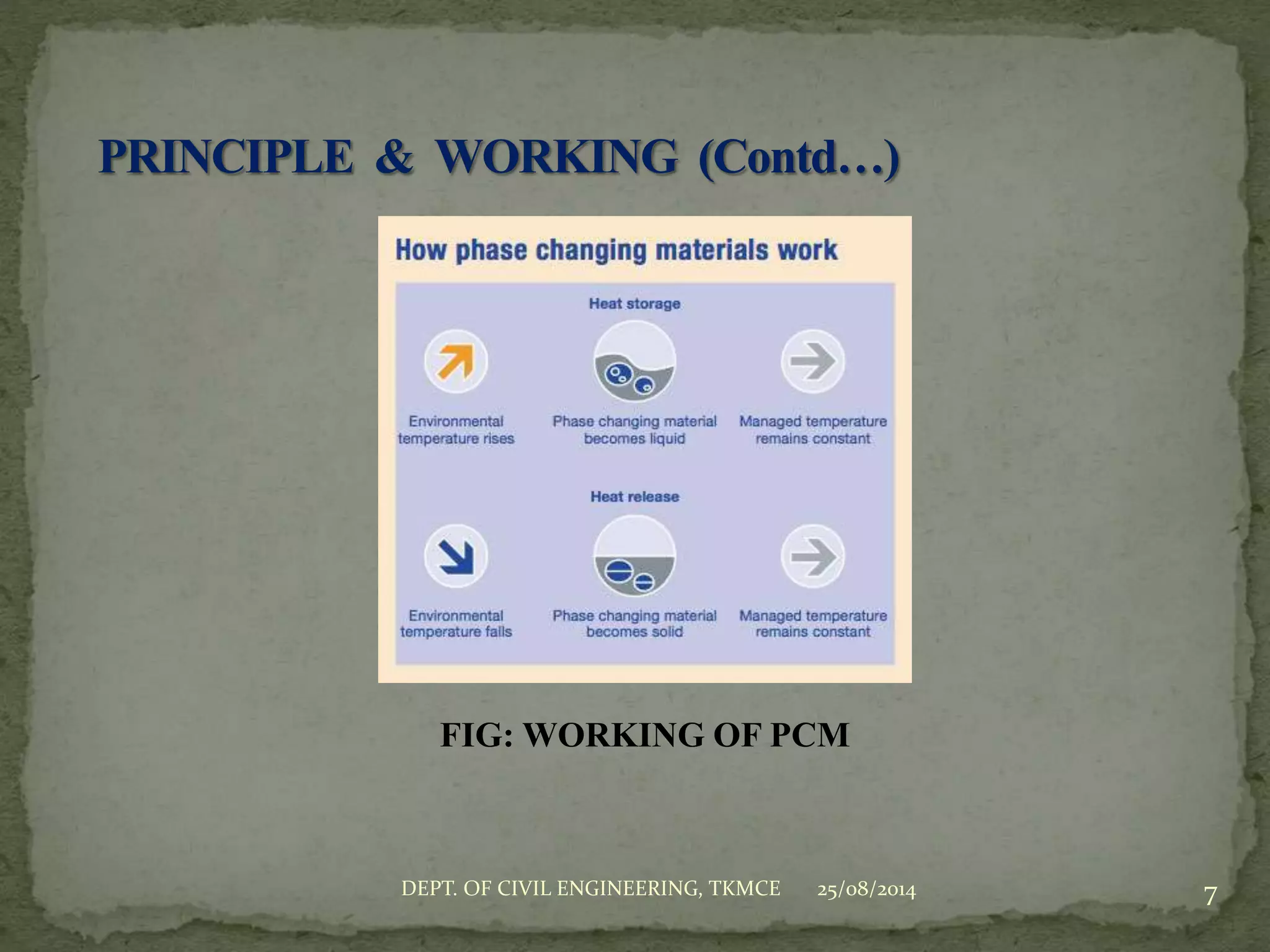

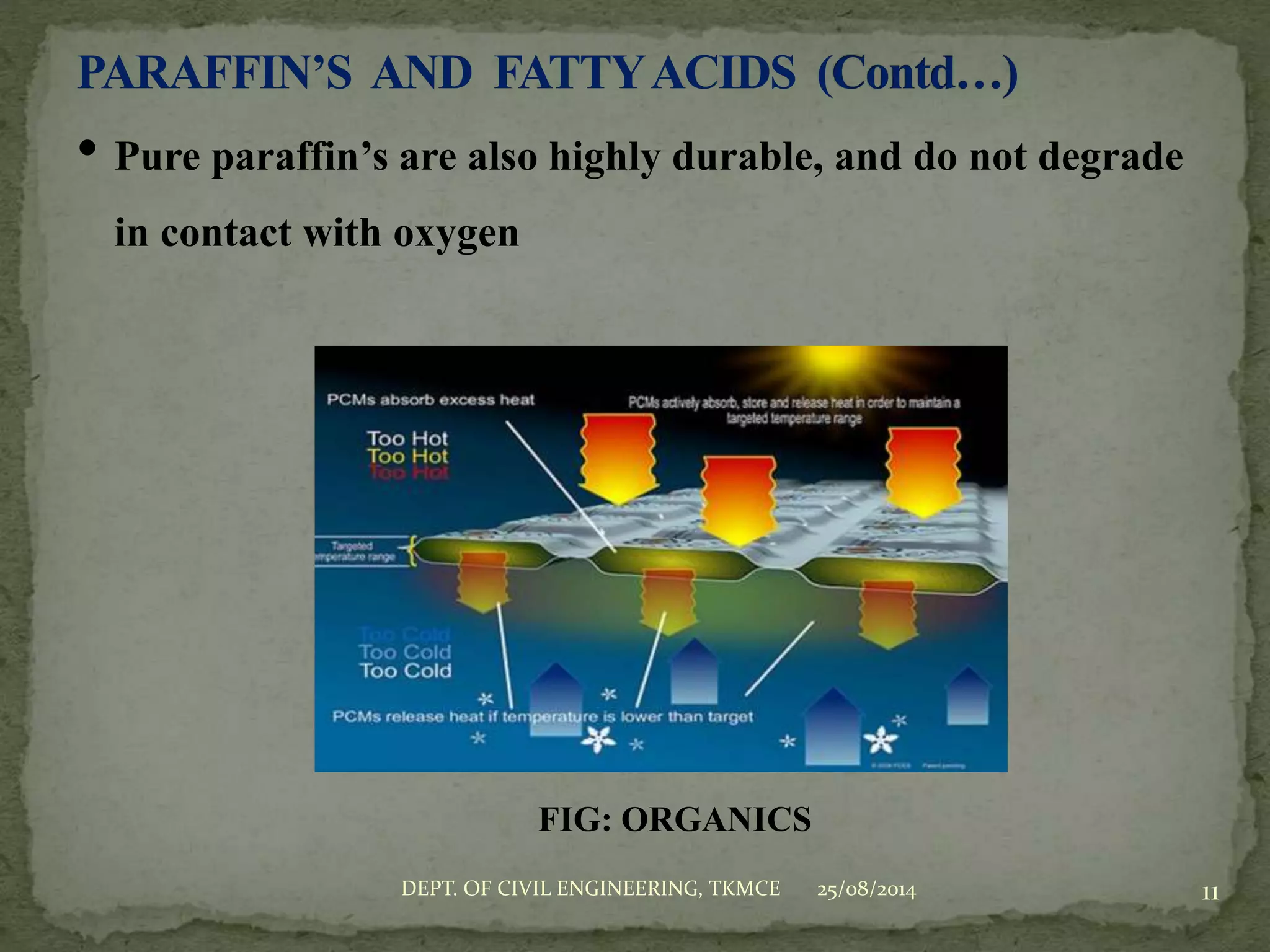

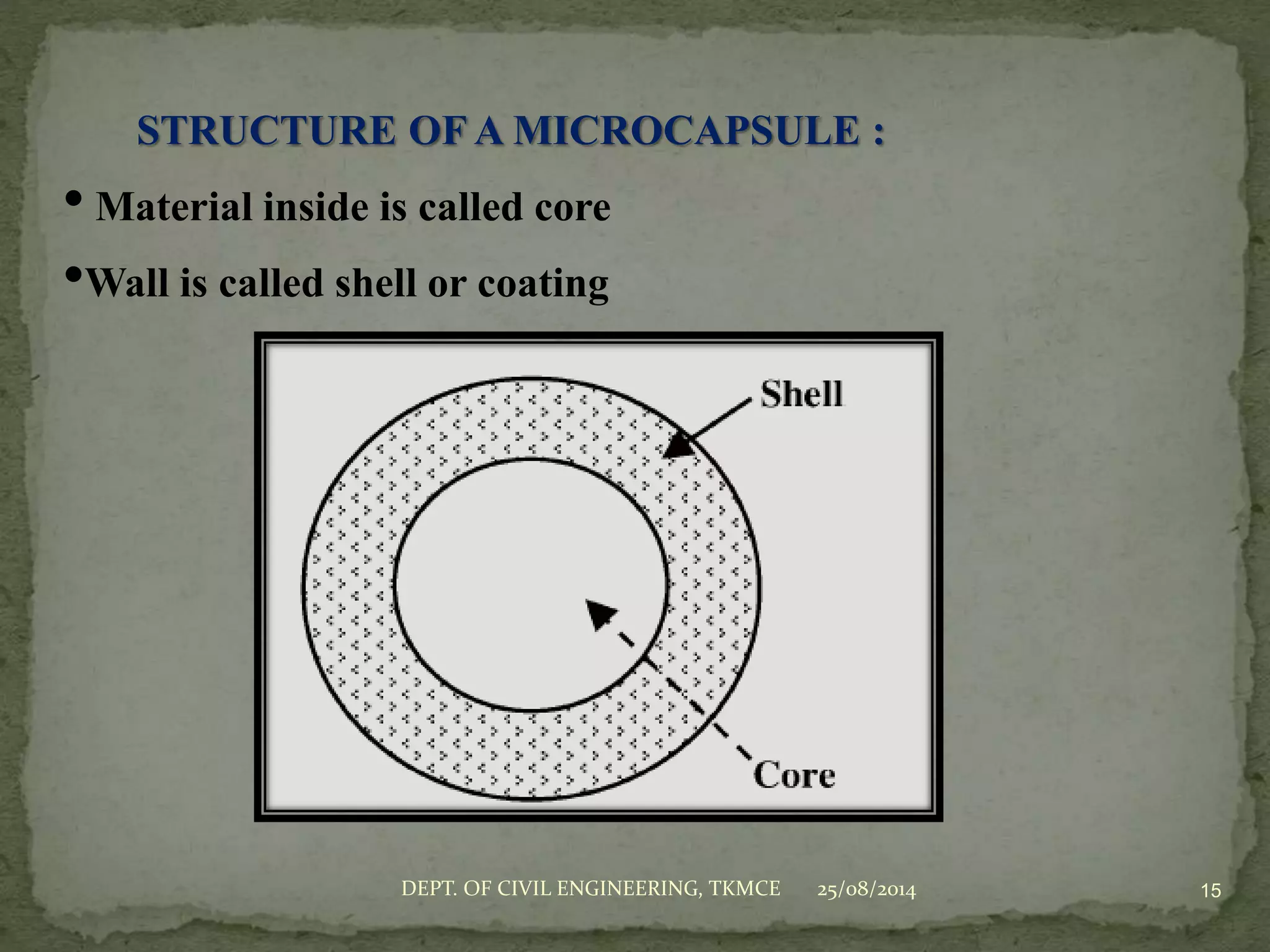

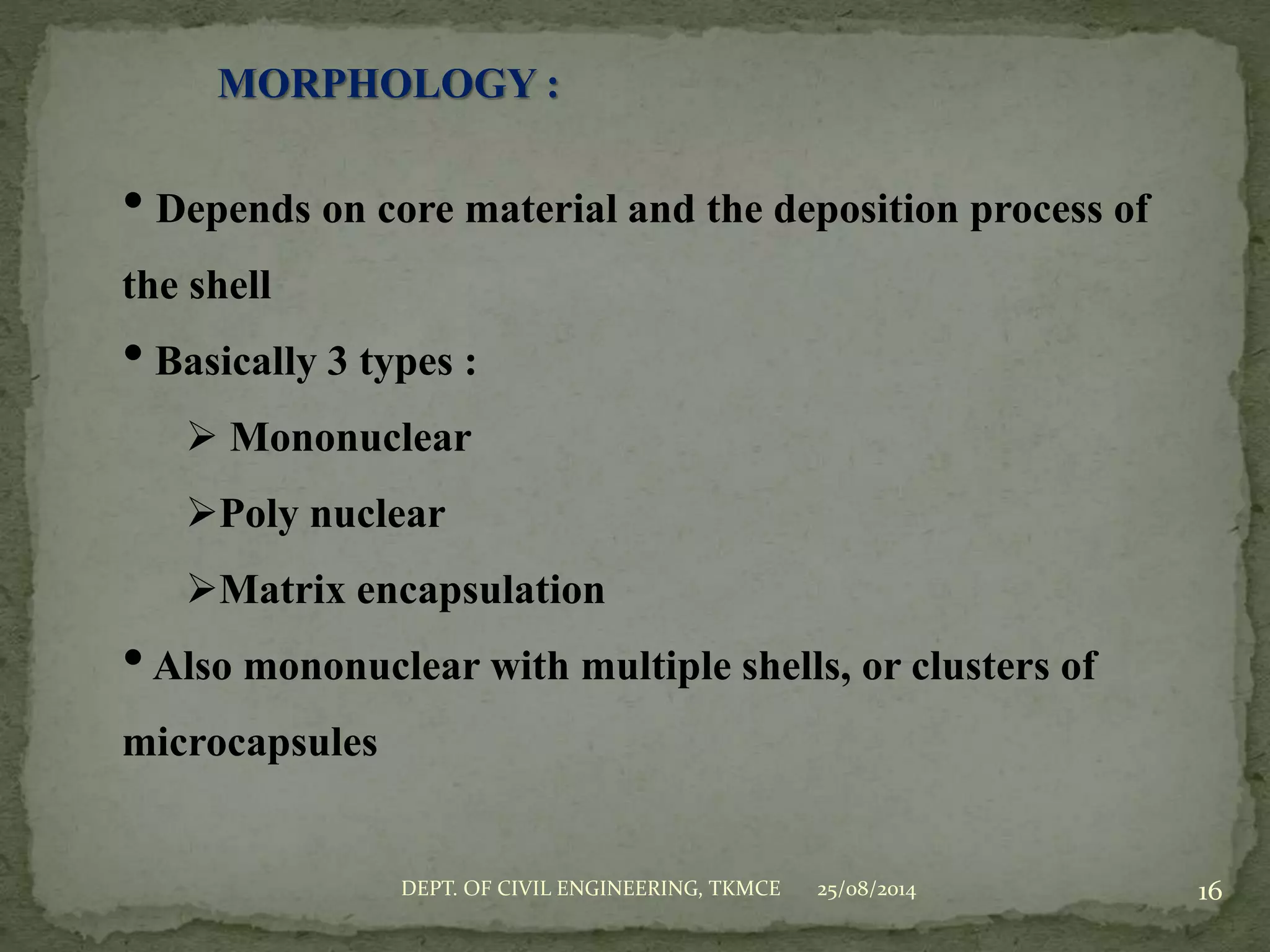

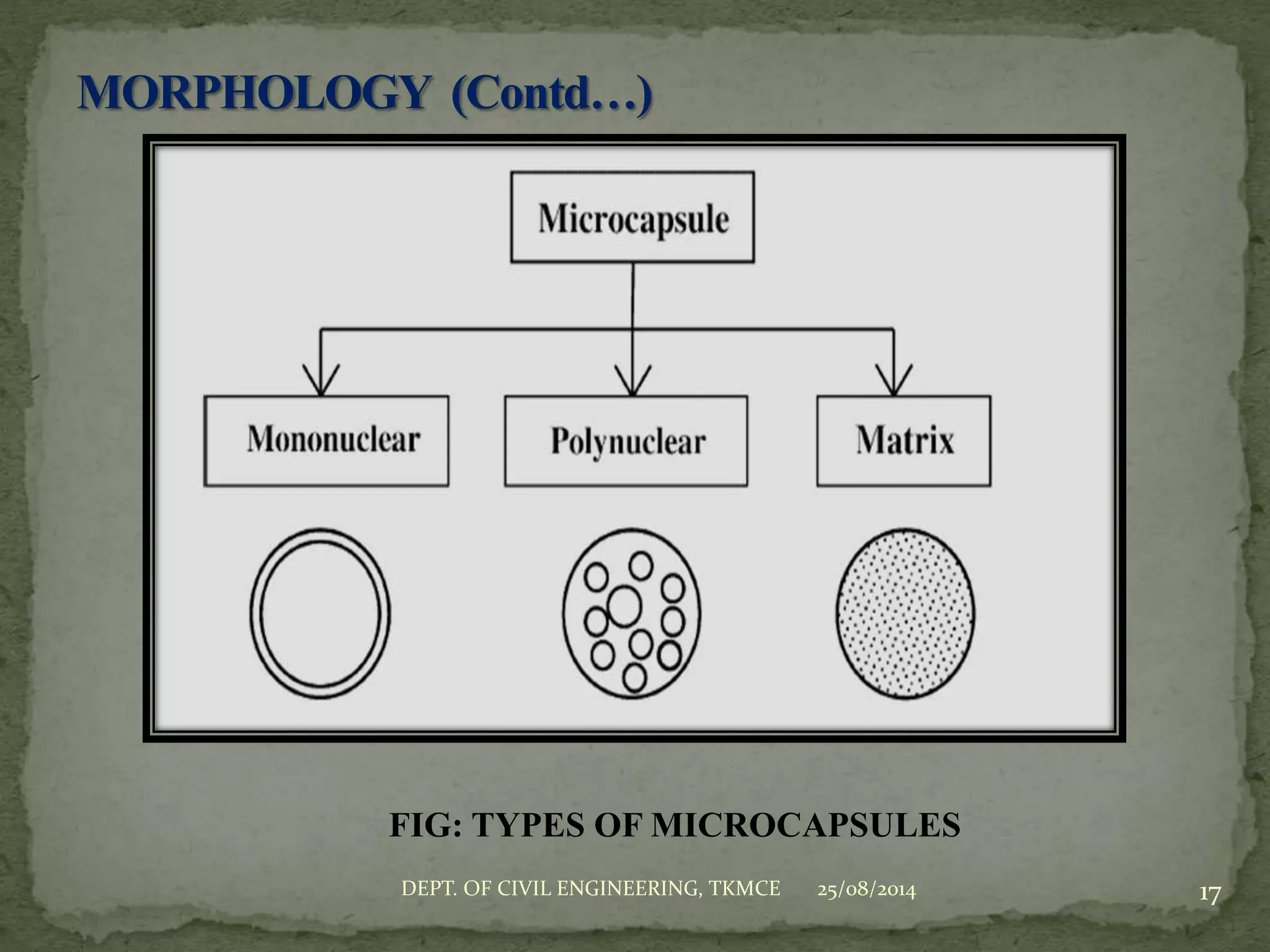

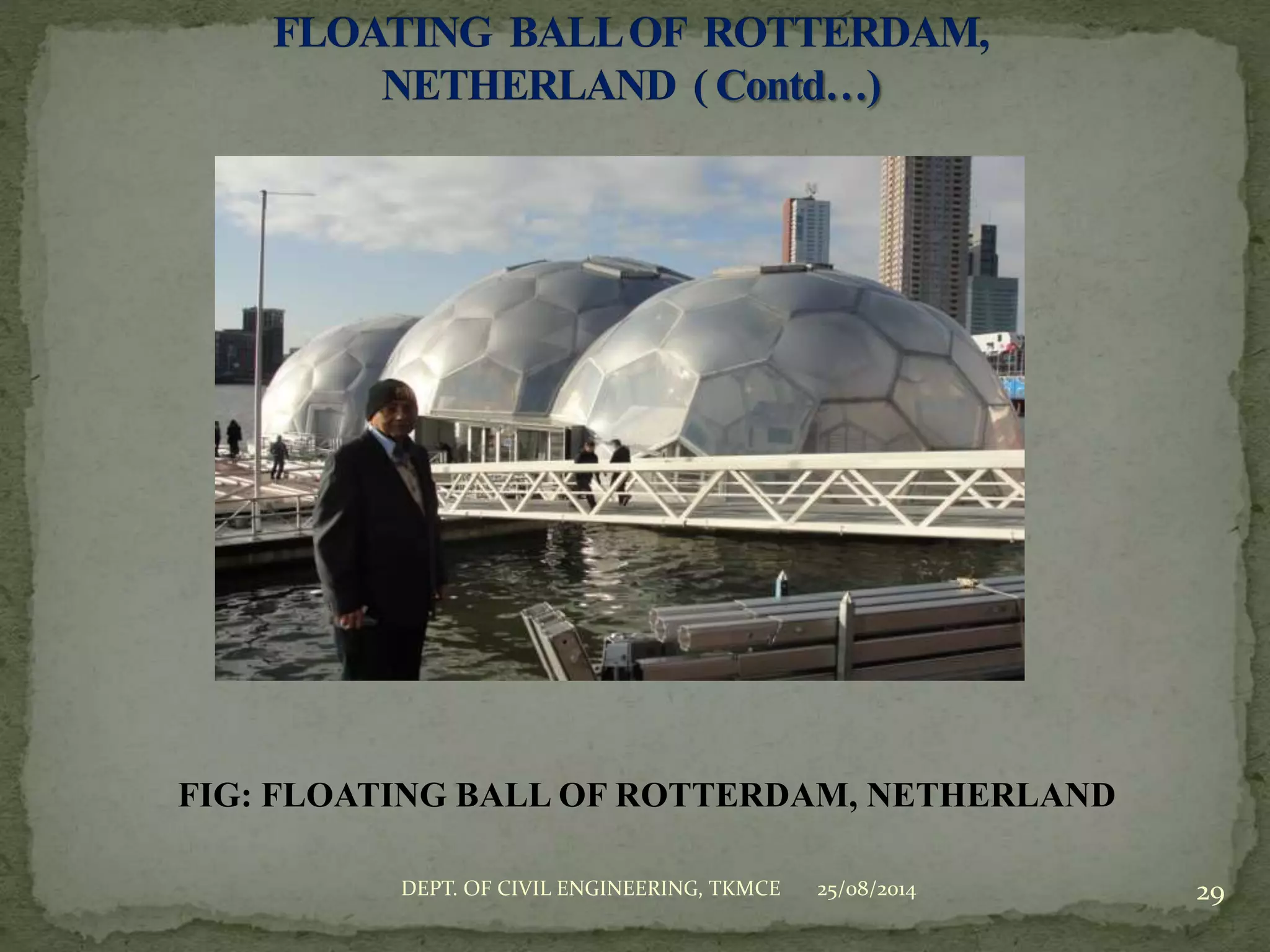

This document discusses phase change materials (PCMs) and their applications in building construction. PCMs can store and release large amounts of thermal energy during phase transitions, helping to regulate indoor temperatures. There are two main types of PCMs used in buildings - inorganic salt hydrates and organic paraffins/fatty acids. PCMs can be incorporated directly into building materials or microencapsulated. The document examines different methods of PCM incorporation and applications like ceiling tiles. Case studies demonstrate how PCMs allow climate control and reduce energy demands in buildings.