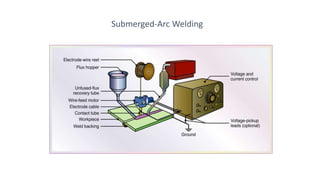

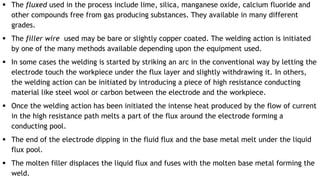

This document provides information about submerged arc welding. It discusses that submerged arc welding involves melting and fusing metals with an electric arc under a blanket of granular flux. The flux protects the weld from impurities and oxygen in the air. It allows for high welding speeds, deep penetration, and produces high quality welds suitable for joining metals like steel. Some key equipment used includes a wire feeder, welding power source, and an arrangement for holding the flux. Submerged arc welding is commonly used in industries like automotive, aviation, shipbuilding, and nuclear power.