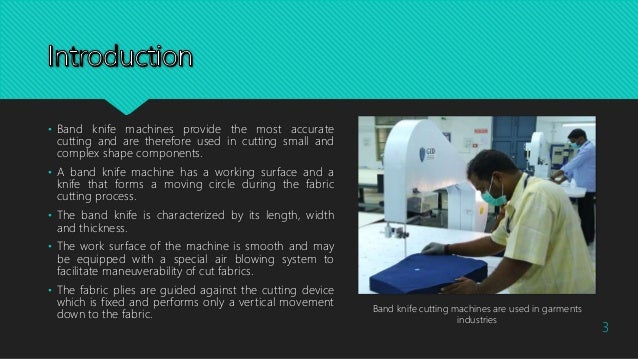

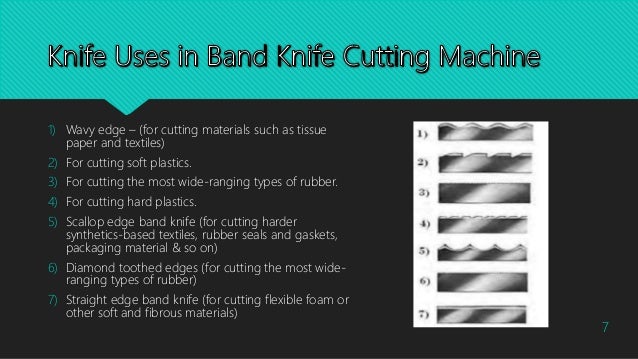

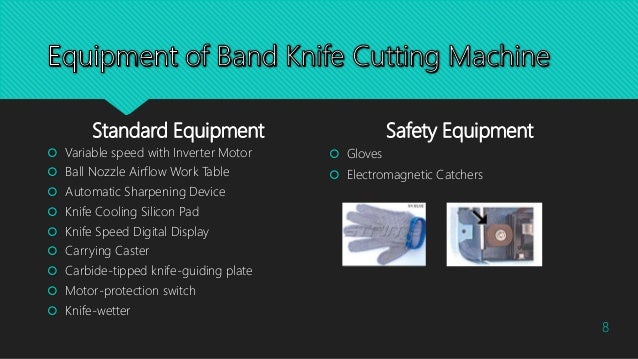

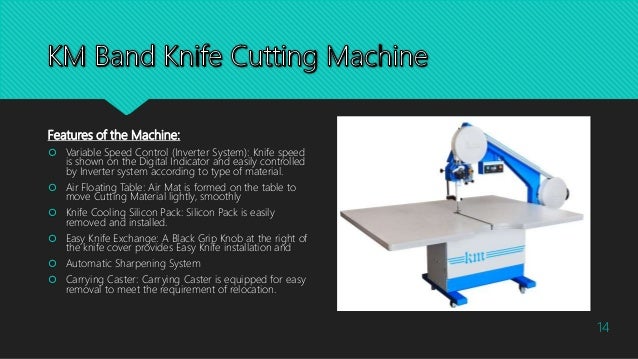

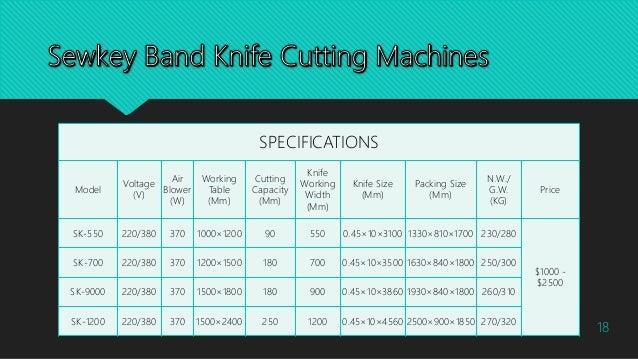

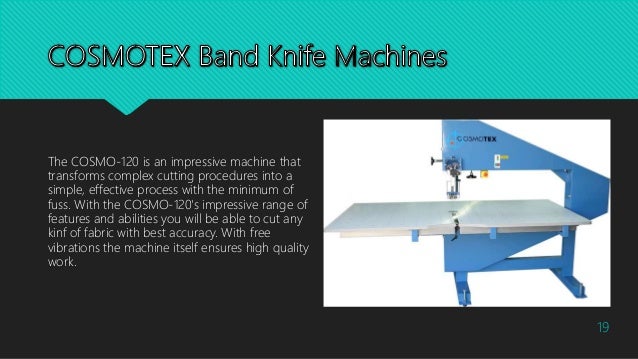

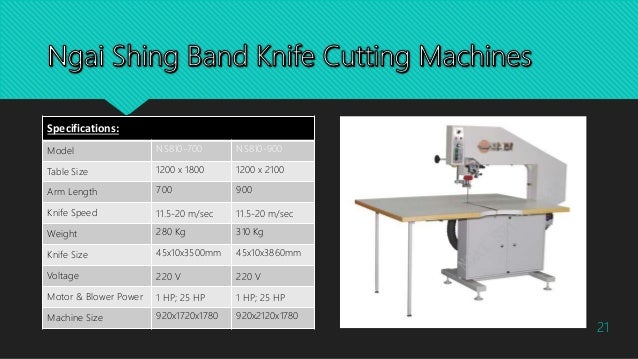

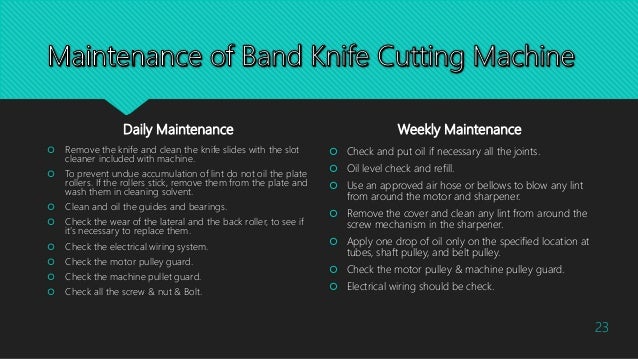

Band knife machines are precision cutting tools used in garment industries for complex shapes and small parts, characterized by a fixed knife and a movable fabric. They offer high productivity for limited products and feature automatic grinders, air blowers, and variable speed control, but are more suitable for smaller components due to table length. Maintenance includes regular cleaning and oiling to ensure performance and longevity.