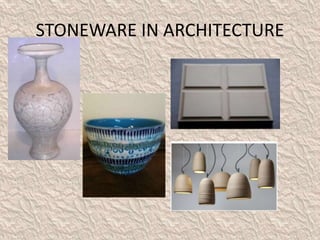

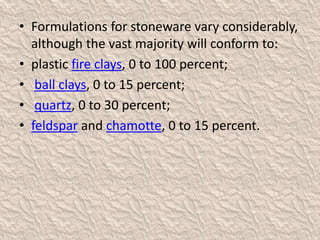

Stoneware is a vitreous or semi-vitreous ceramic made from stoneware clay or fire clay. It is fired at high temperatures between 1200-1300°C and cooled slowly, making it nonporous and hard. Common uses include art pottery, plates, bowls, and jugs. There are different types of stoneware including traditional, fine, chemical, and thermal shock resistant stoneware used for various applications. Stoneware is known for its stone-like characteristics including a hard, dense surface that can be colored grey, brown, or off-white.