Embed presentation

Download as PDF, PPTX

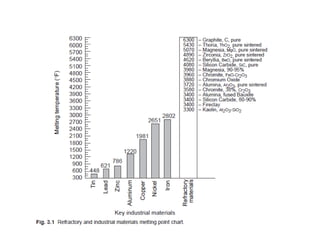

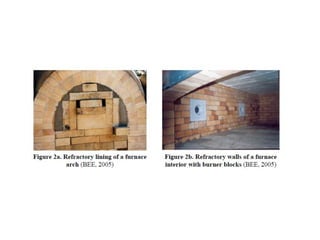

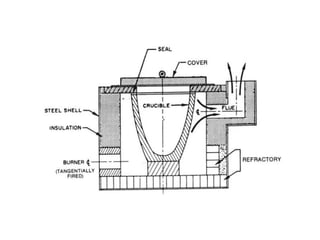

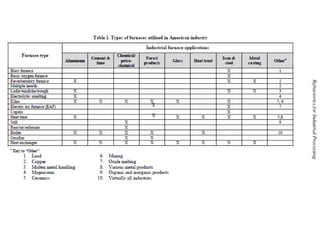

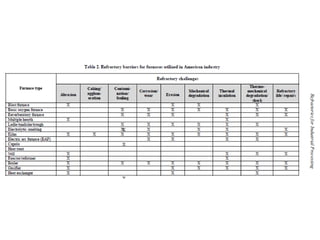

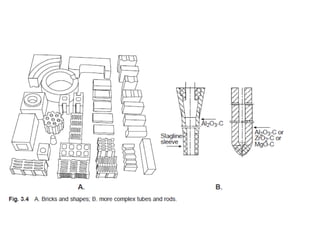

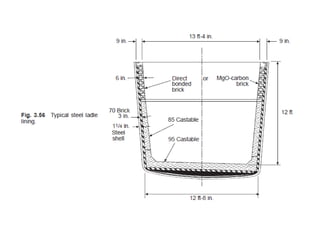

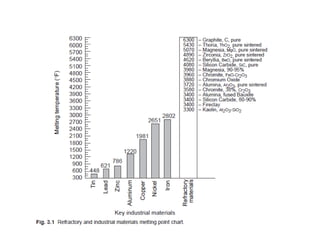

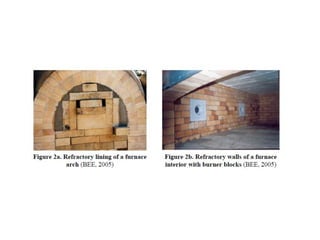

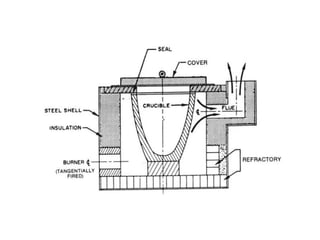

Refractories are nonmetallic materials that maintain their structure at high temperatures. They are used in industries like iron and steel production, cement, lime, ceramics, and glass manufacturing where they are exposed to heat, thermal cycling, erosion, corrosion, and mechanical stress. The iron and steel industry consumes 70% of refractories globally. Refractories have been used since the Stone Age to contain fire. Common refractory materials include oxides found in nature like dolomite and magnesia from seawater. Producing refractories can involve special processes and coating methods due to their high cost and need to withstand extreme conditions.