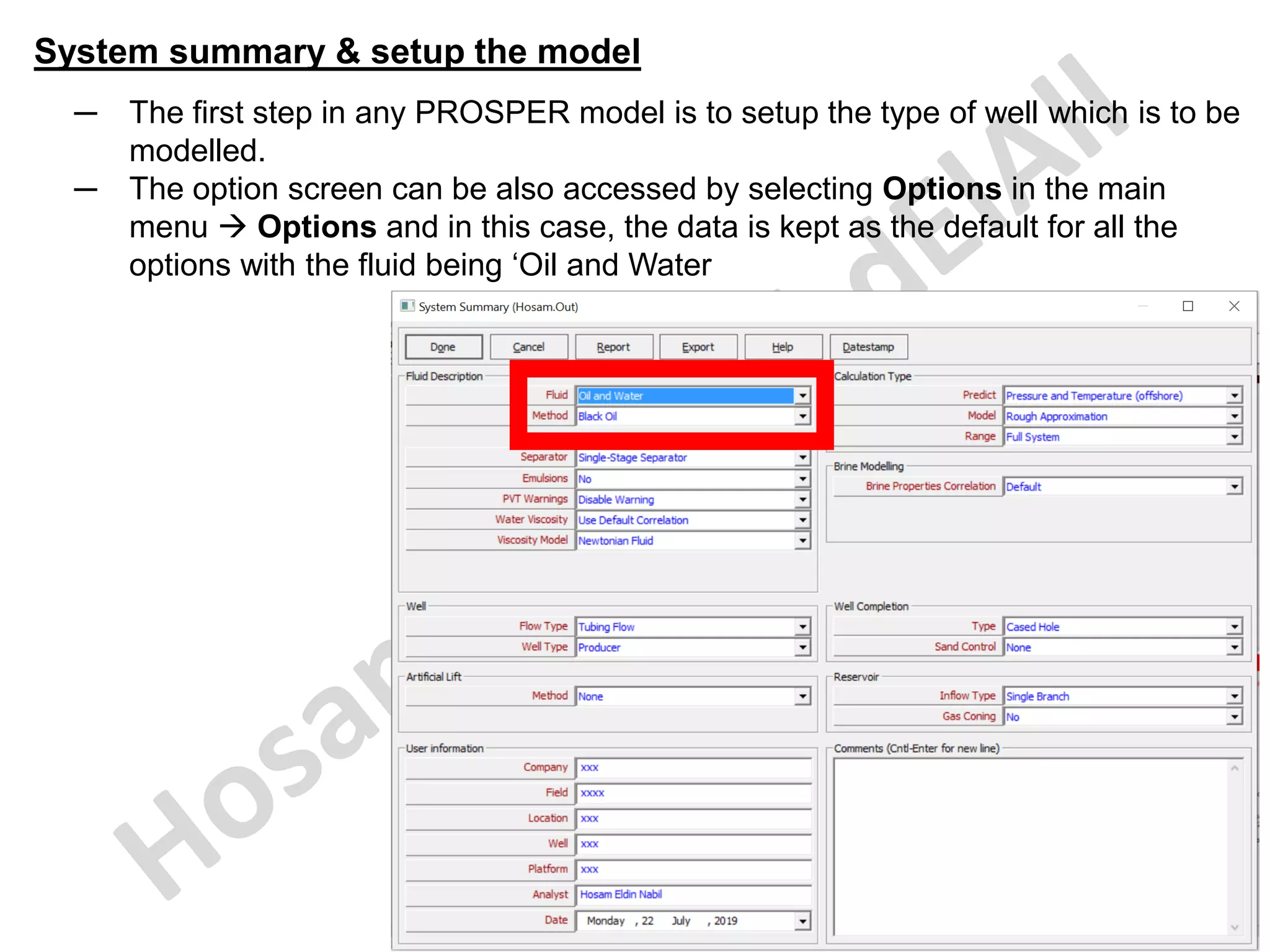

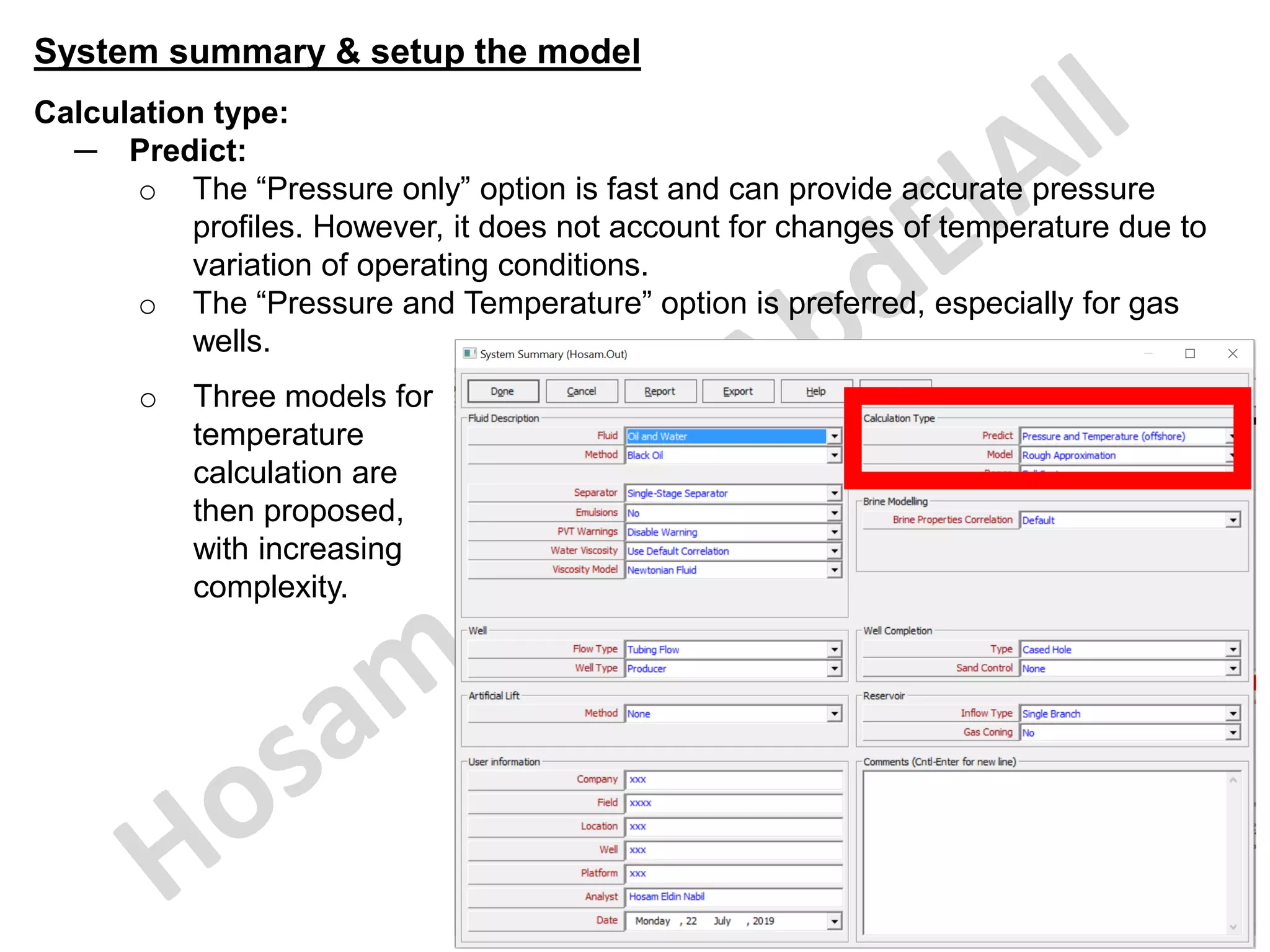

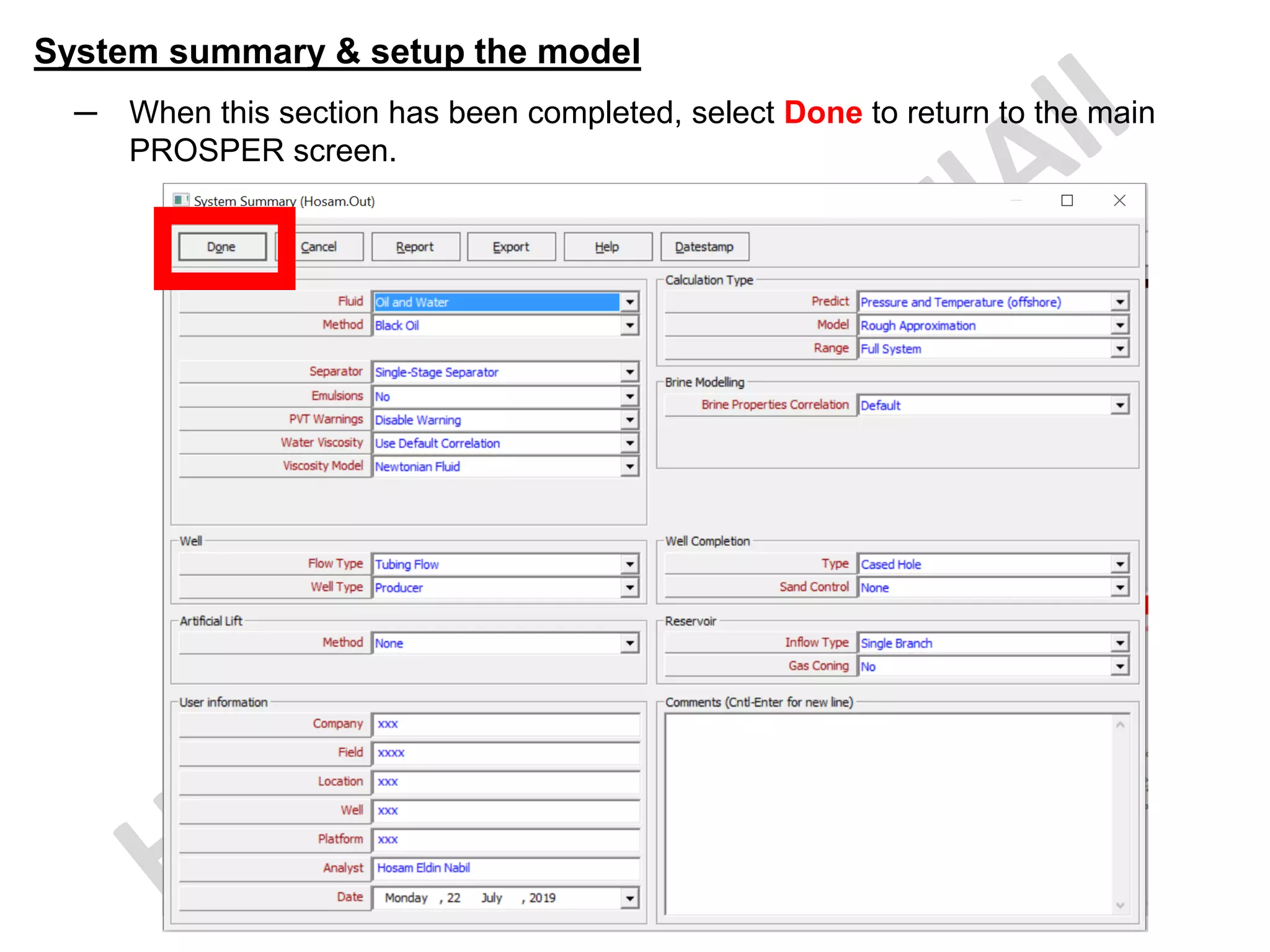

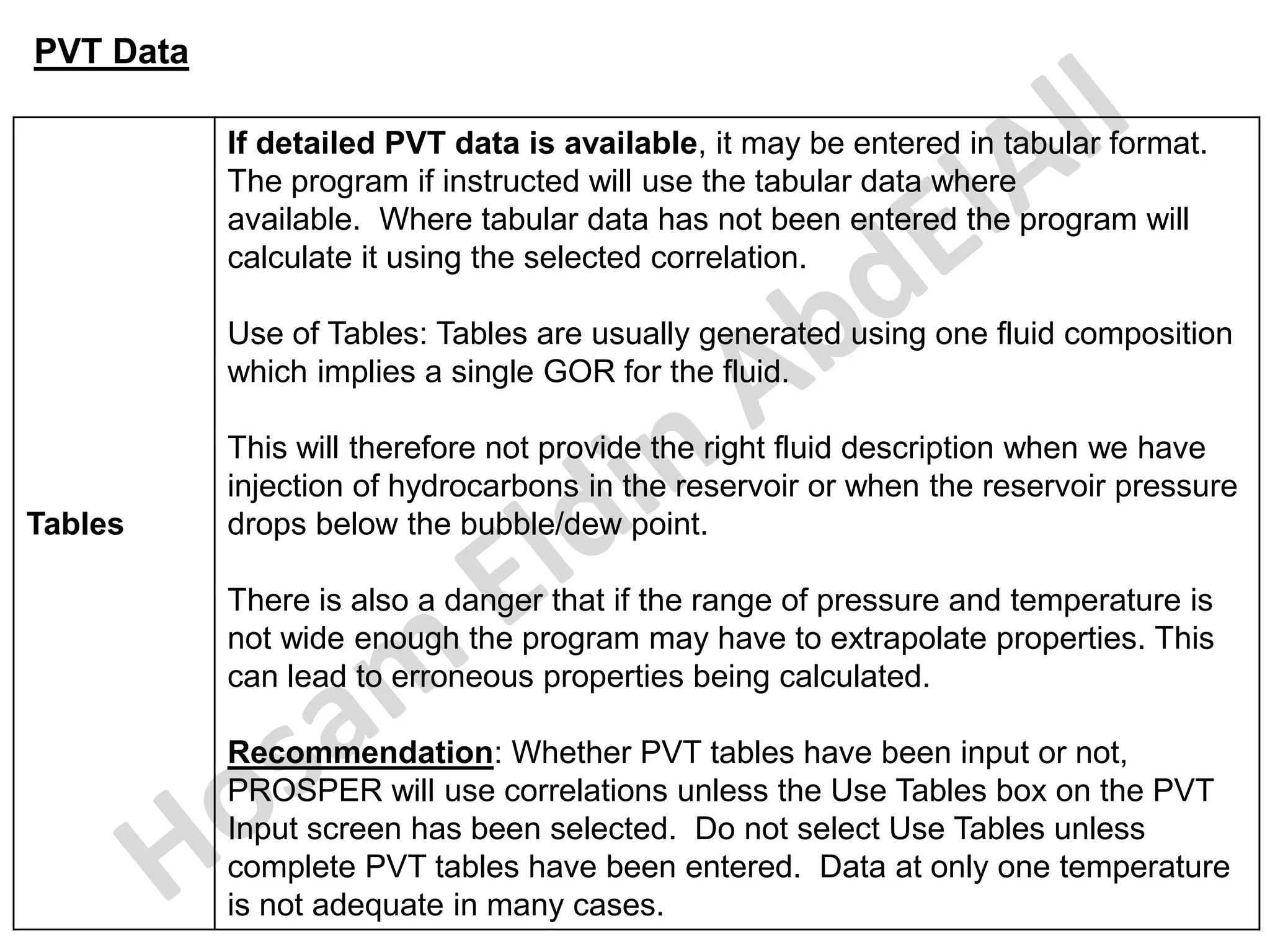

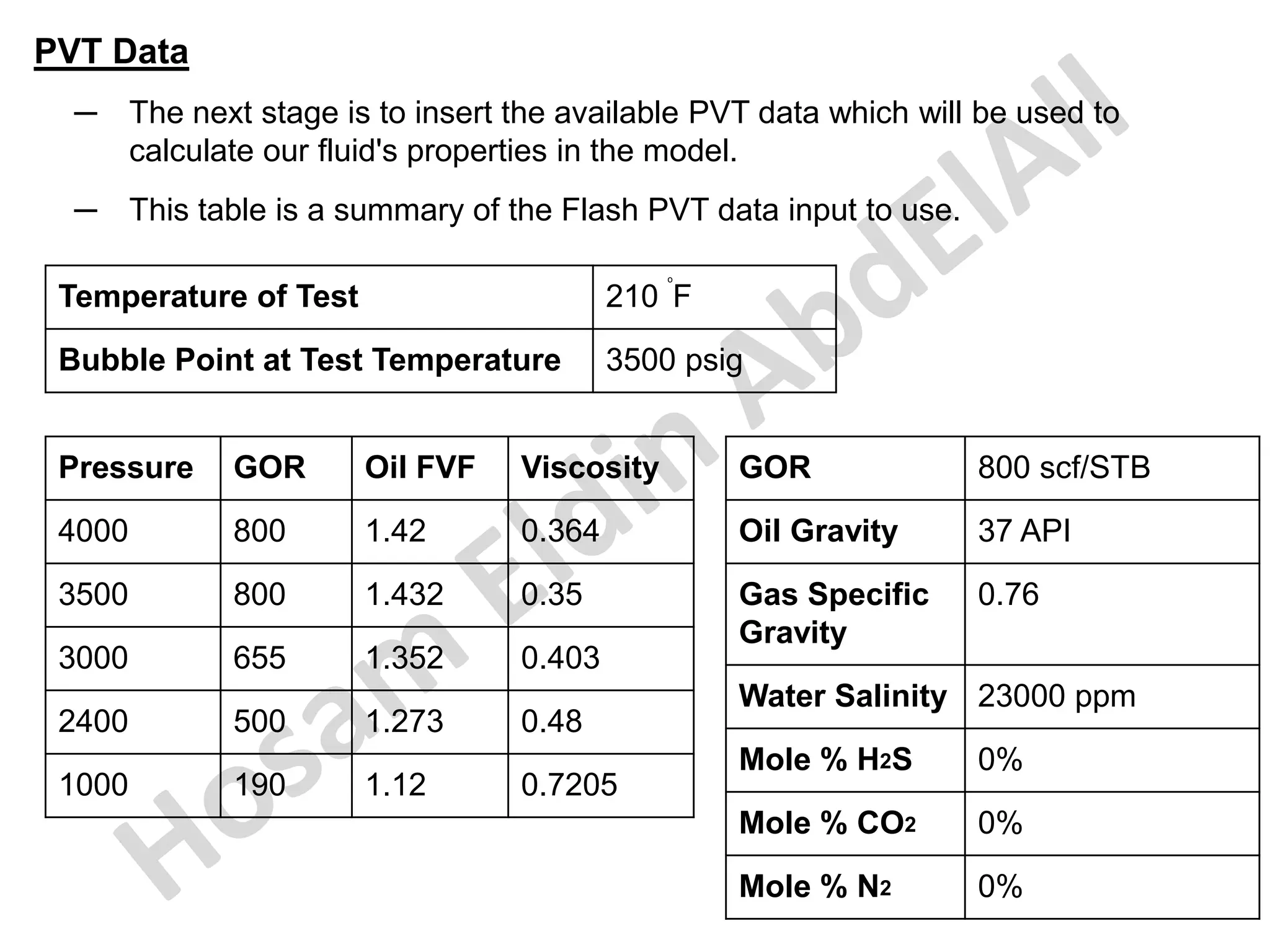

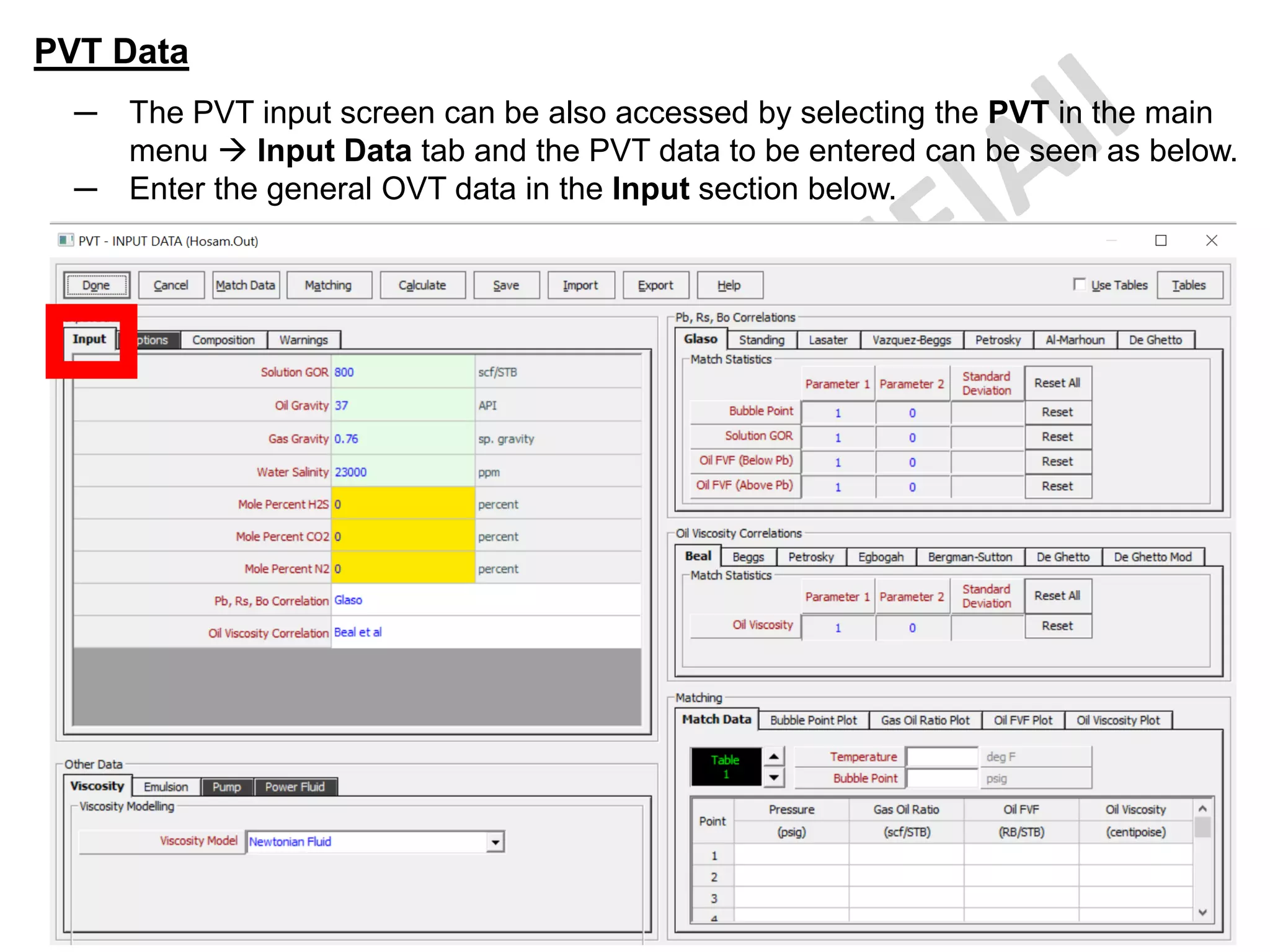

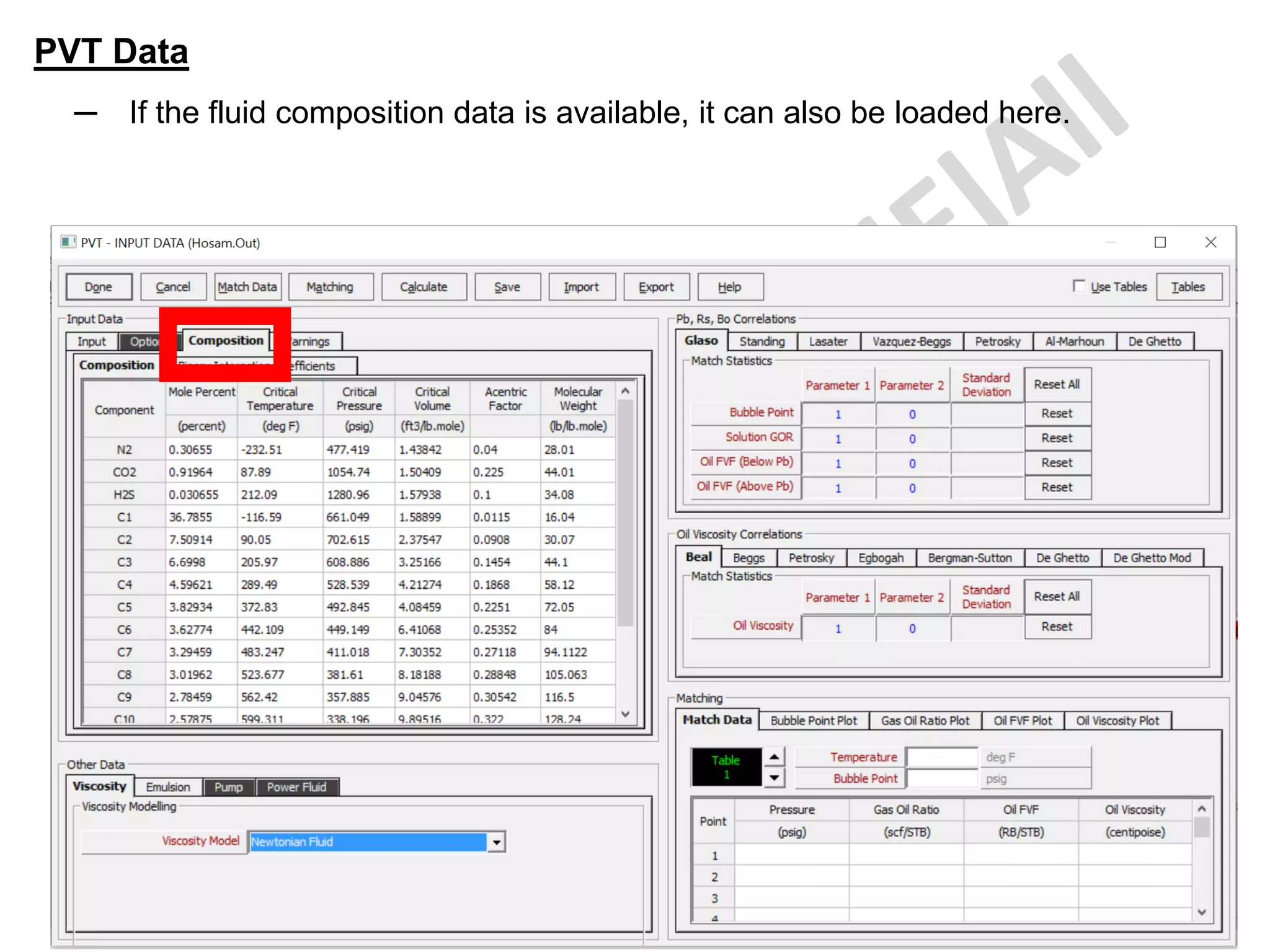

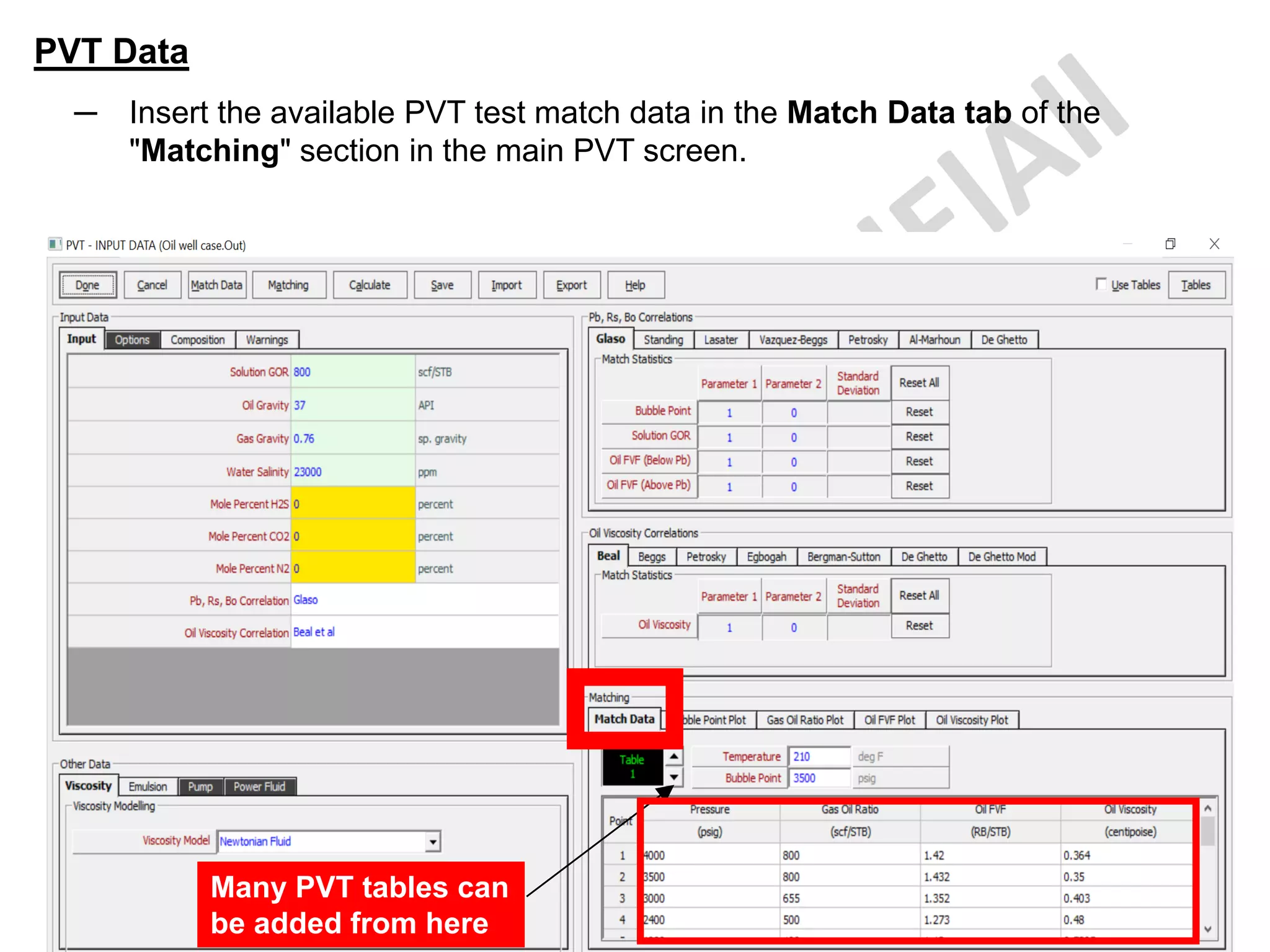

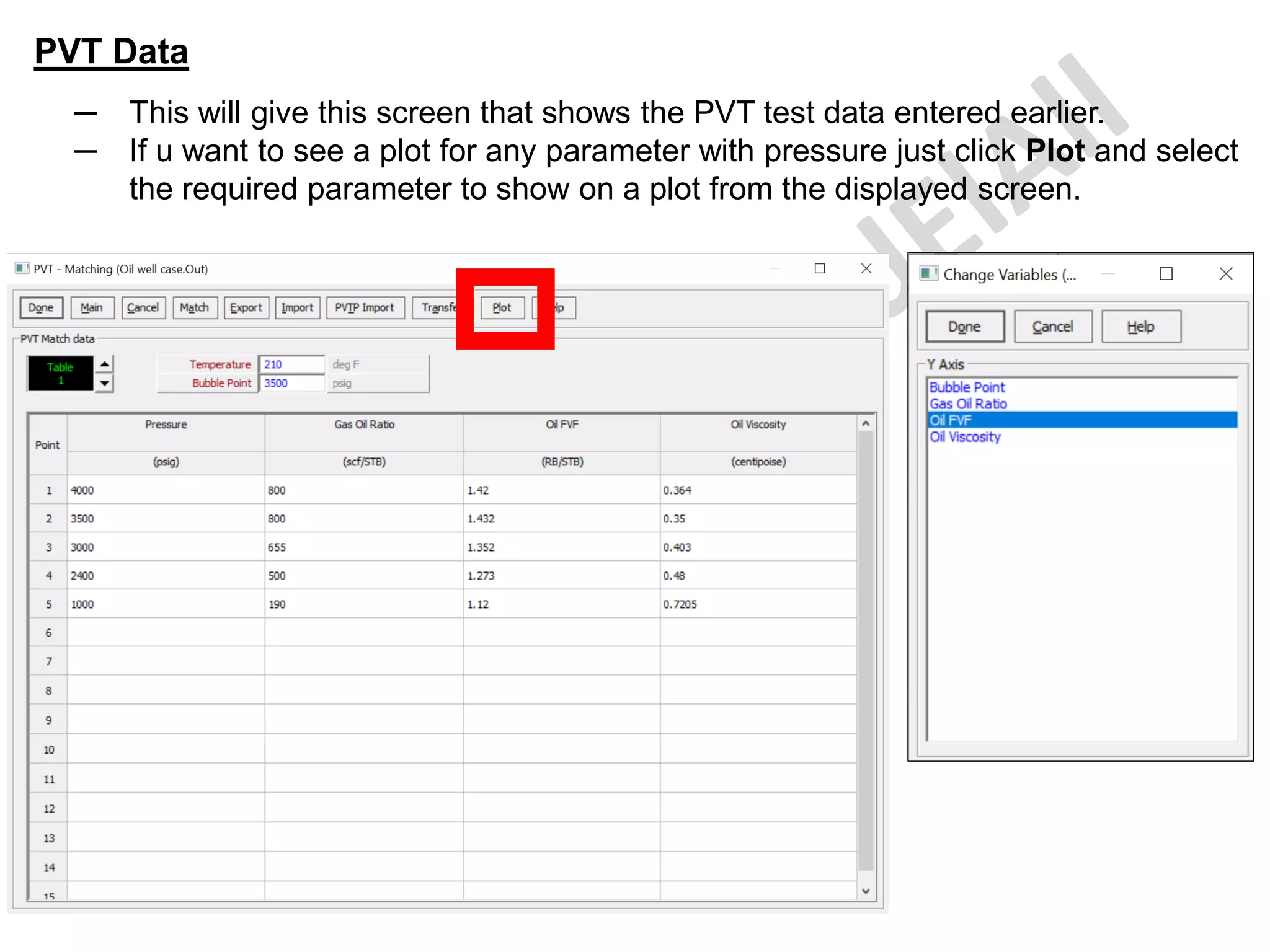

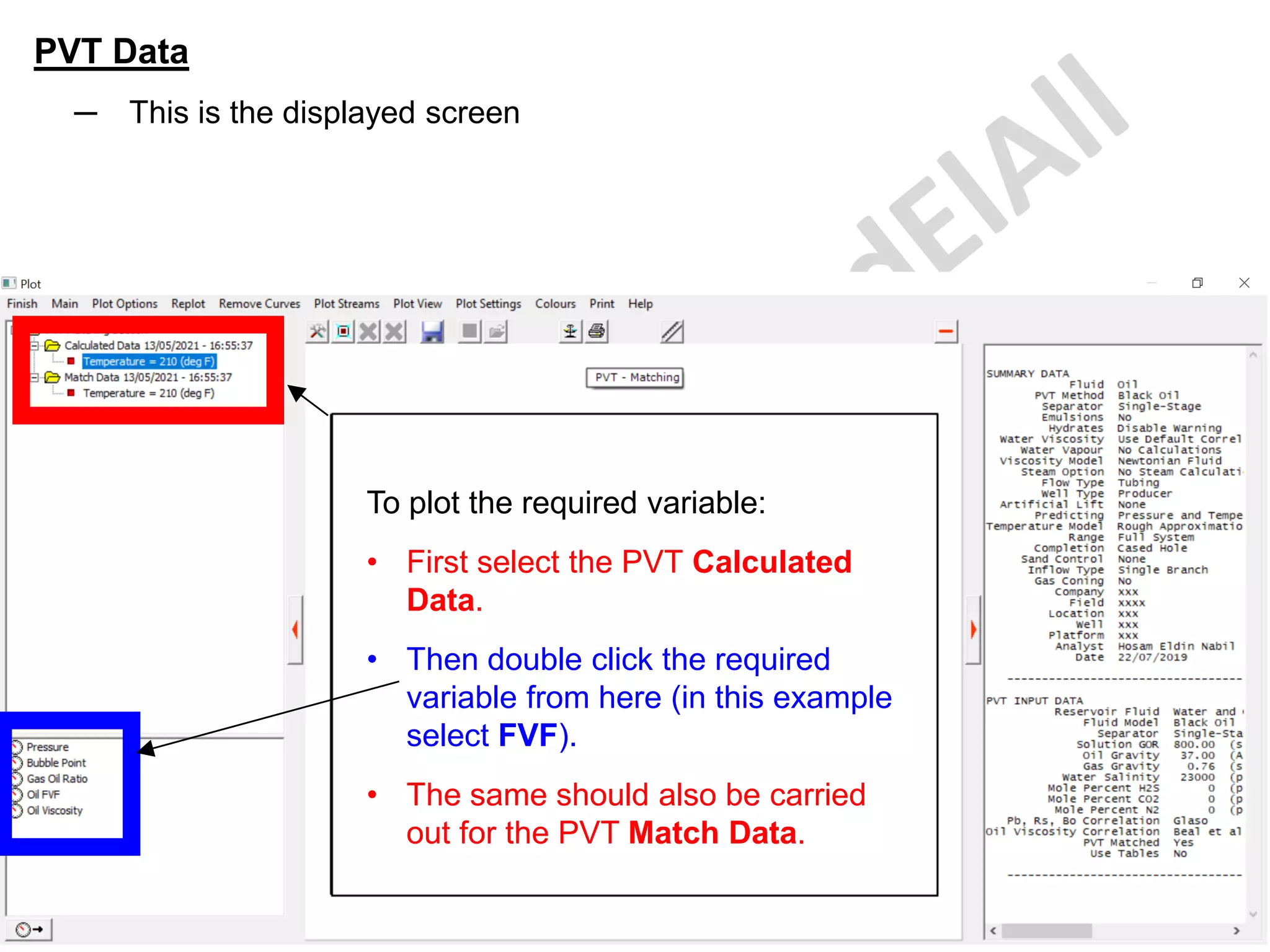

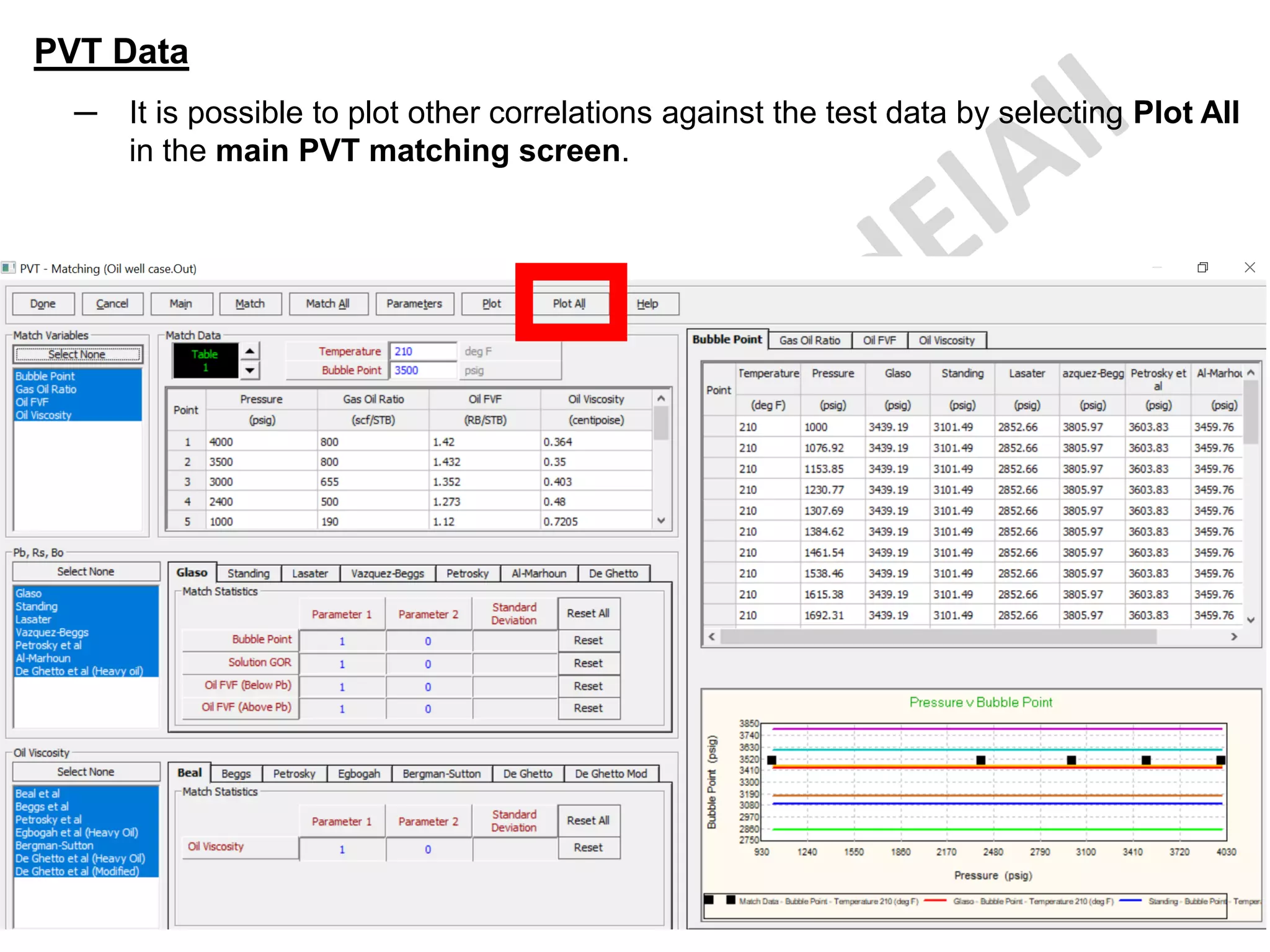

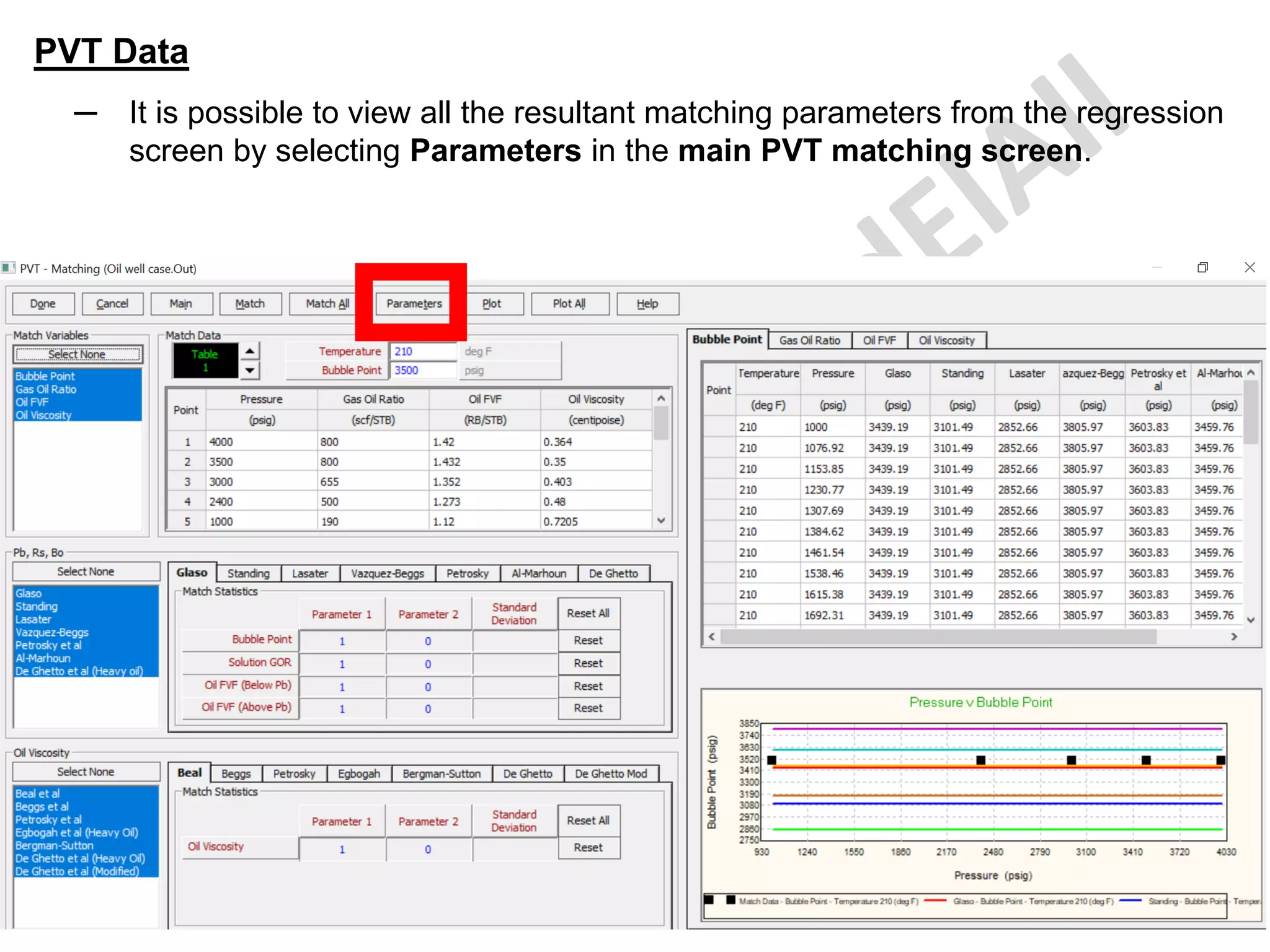

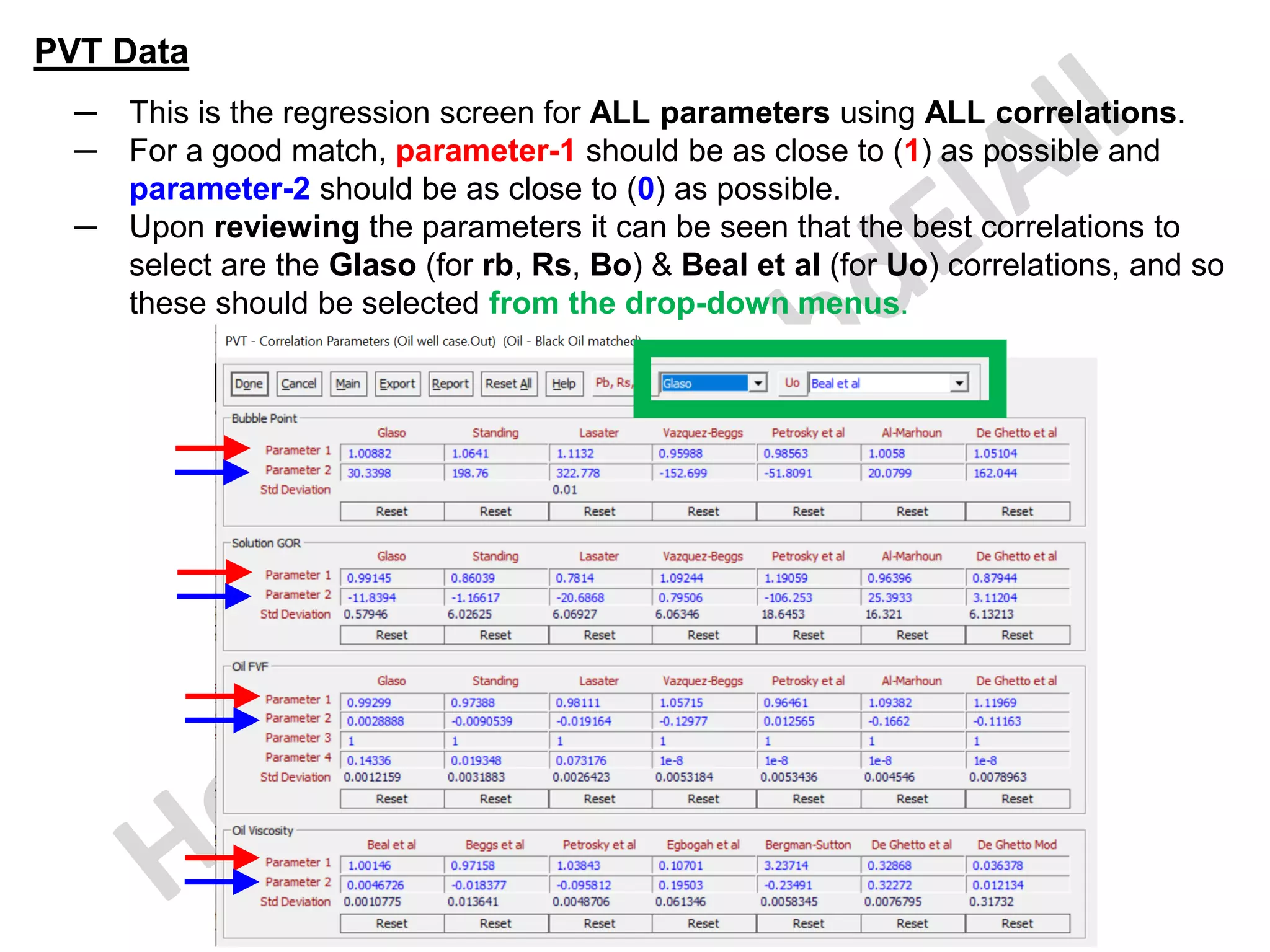

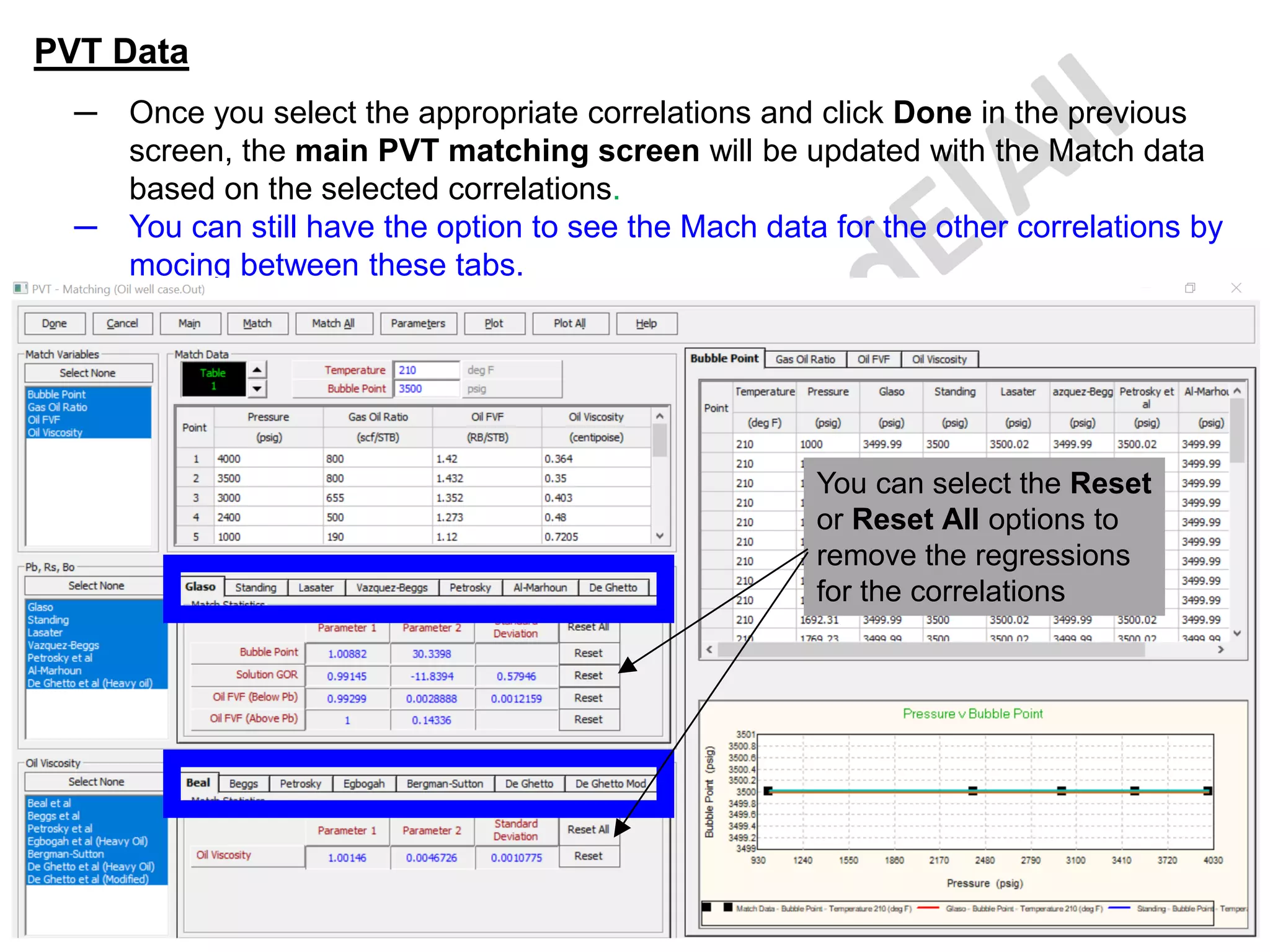

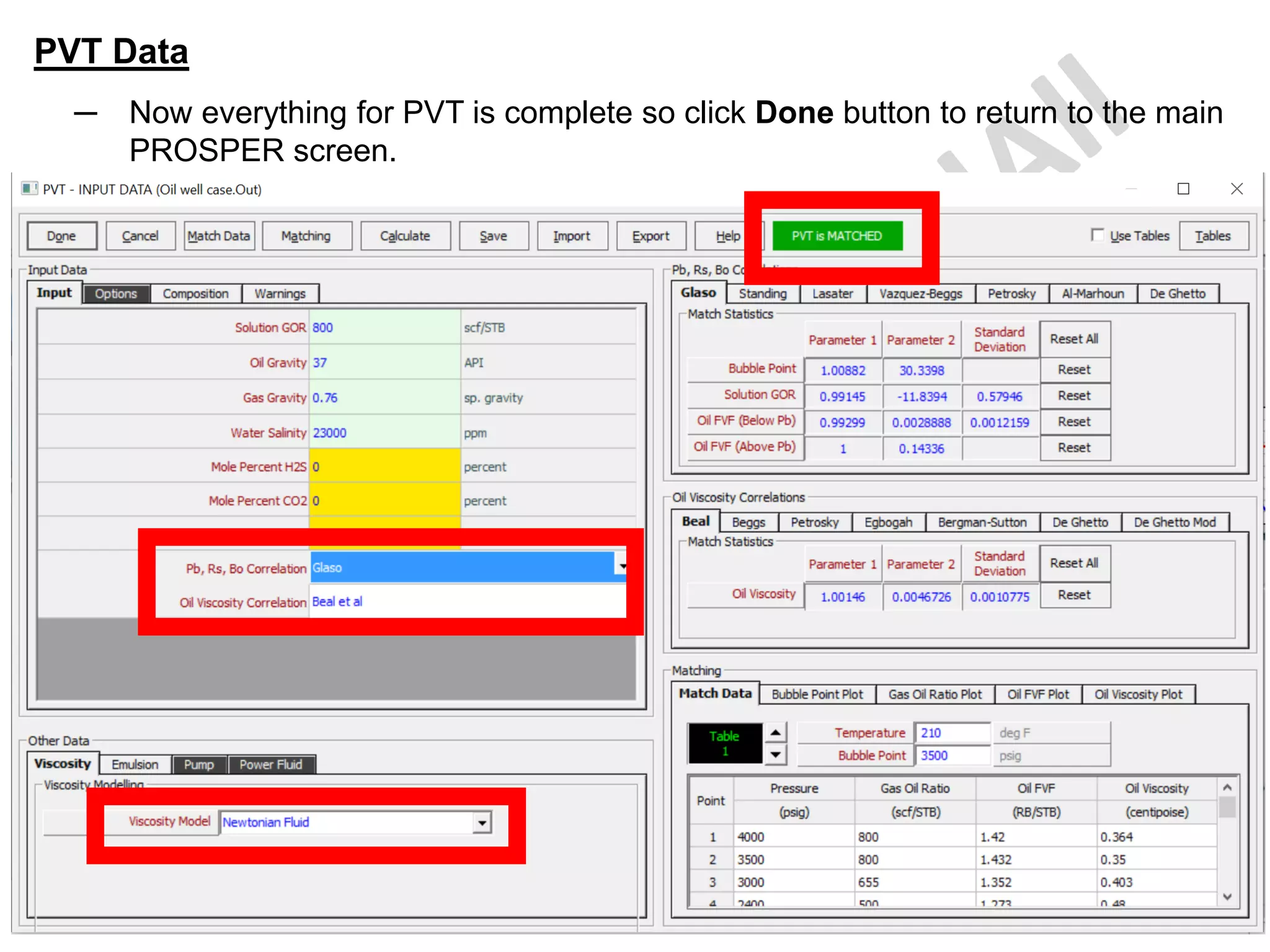

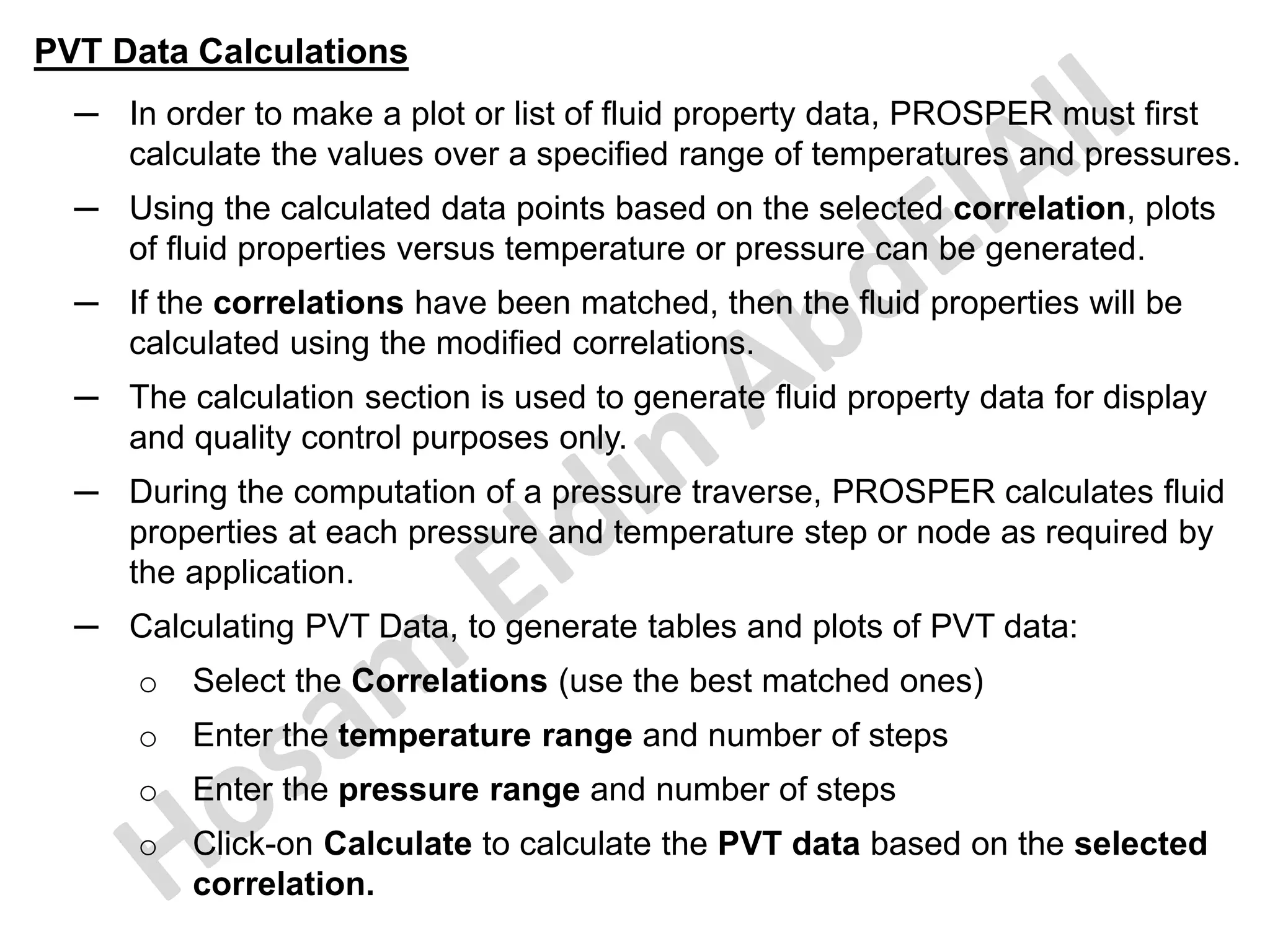

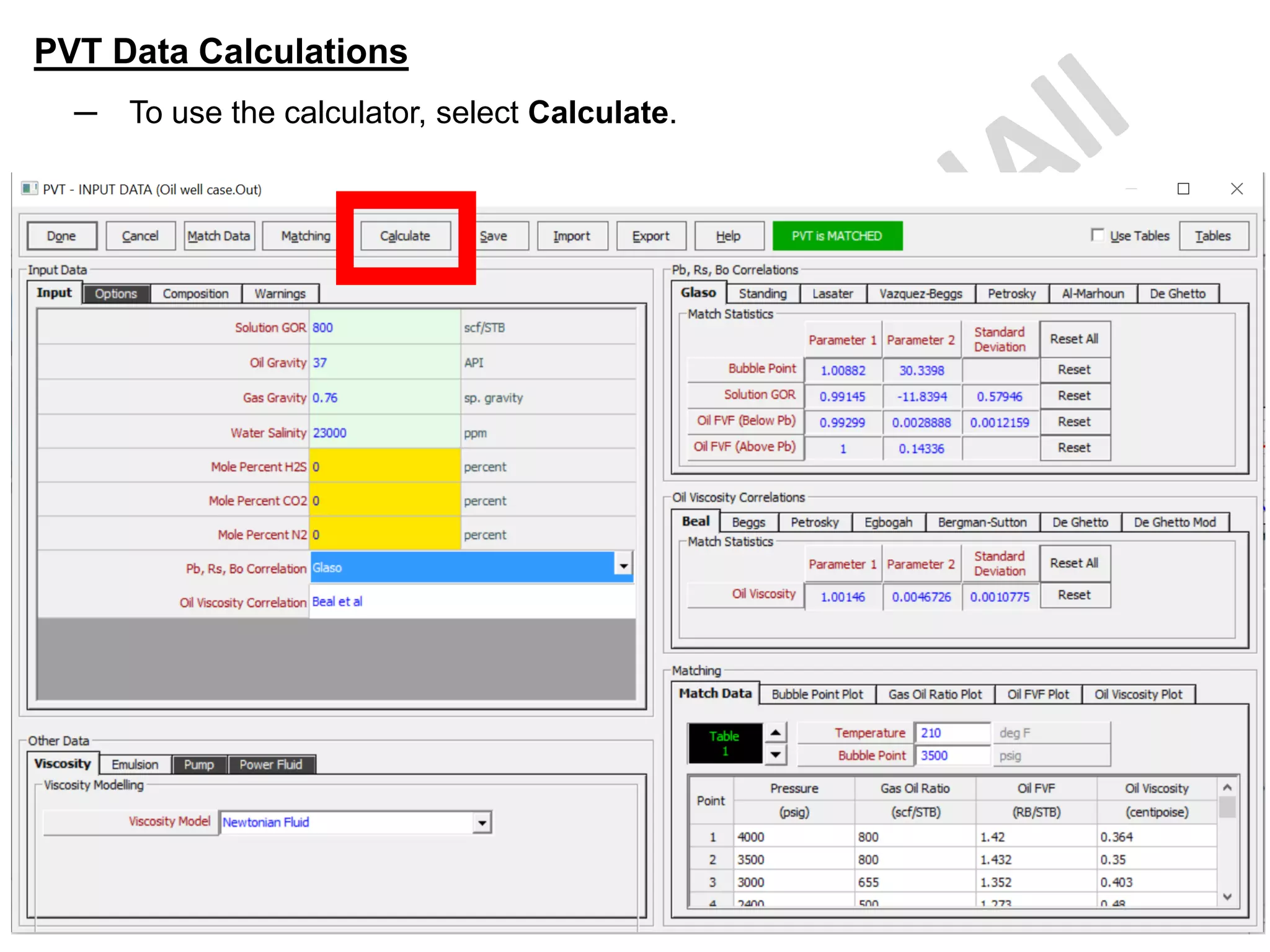

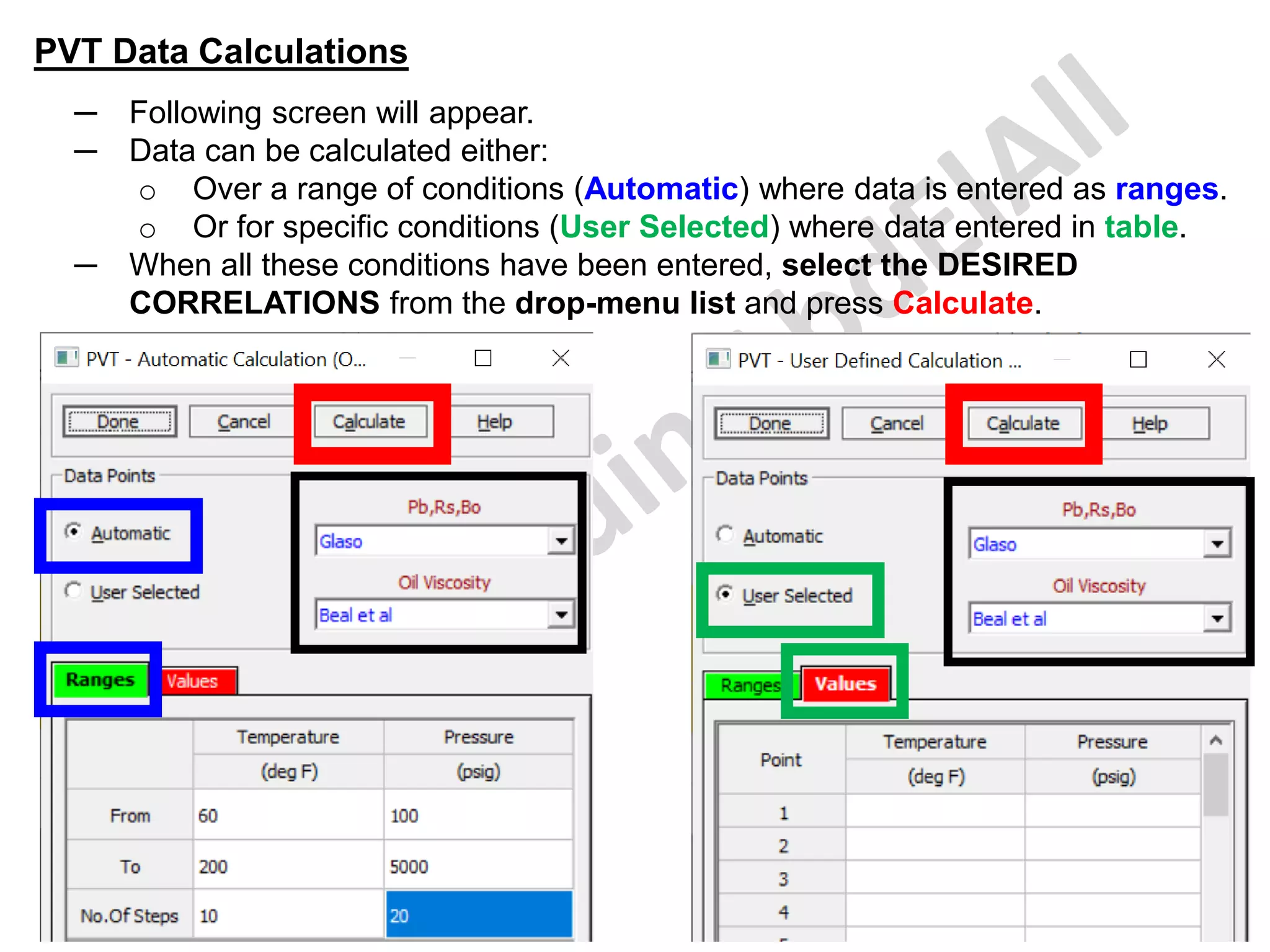

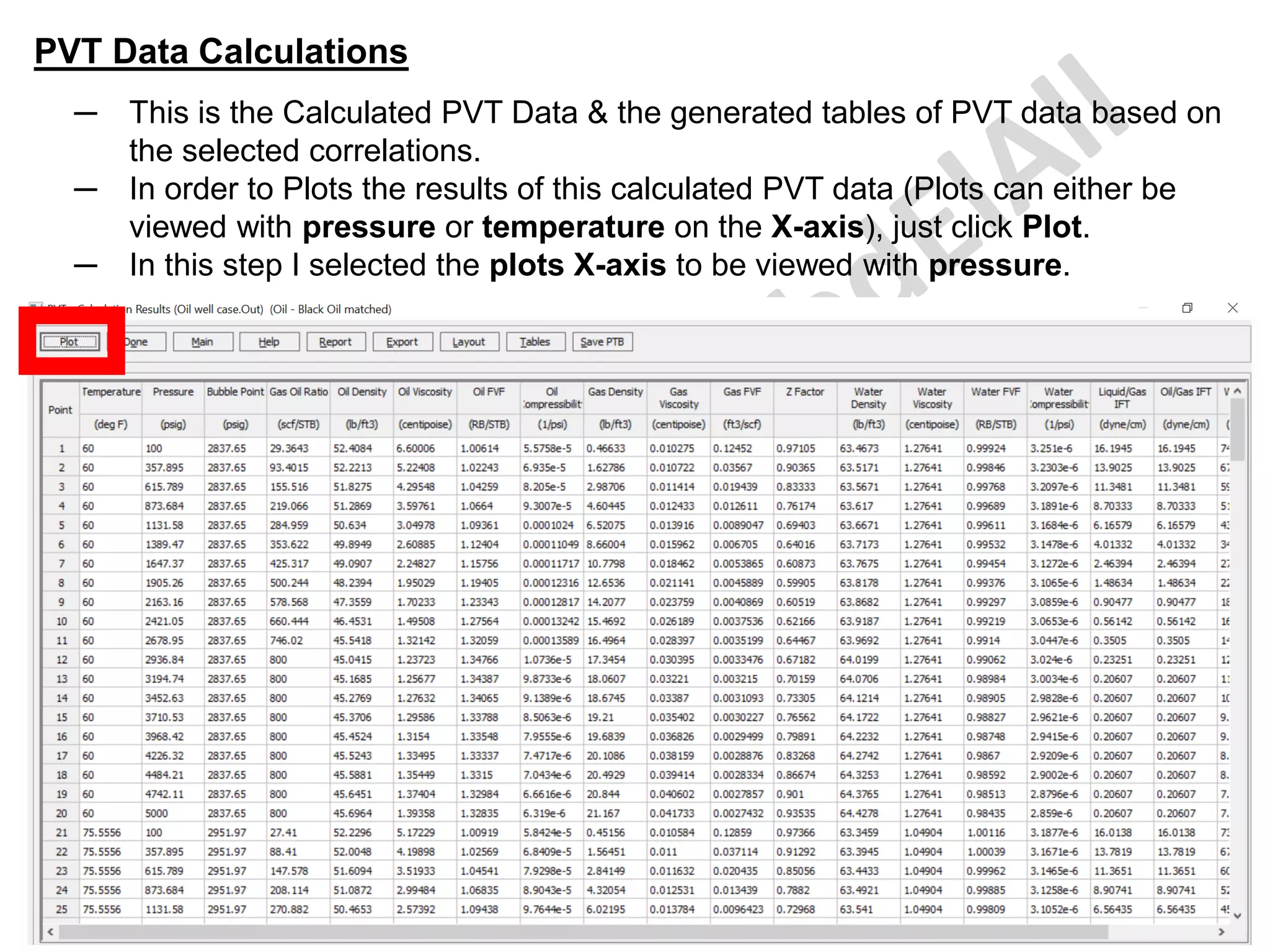

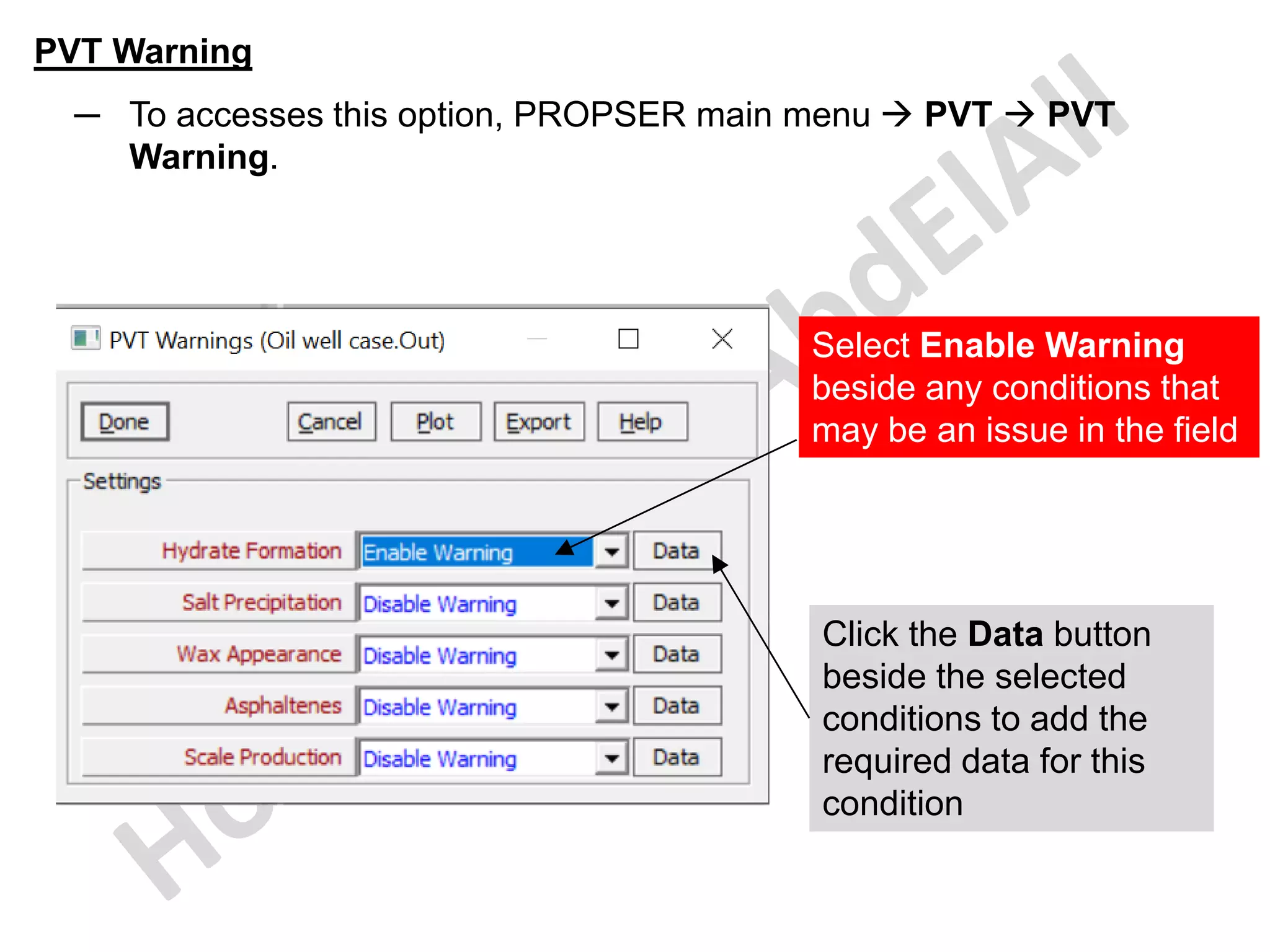

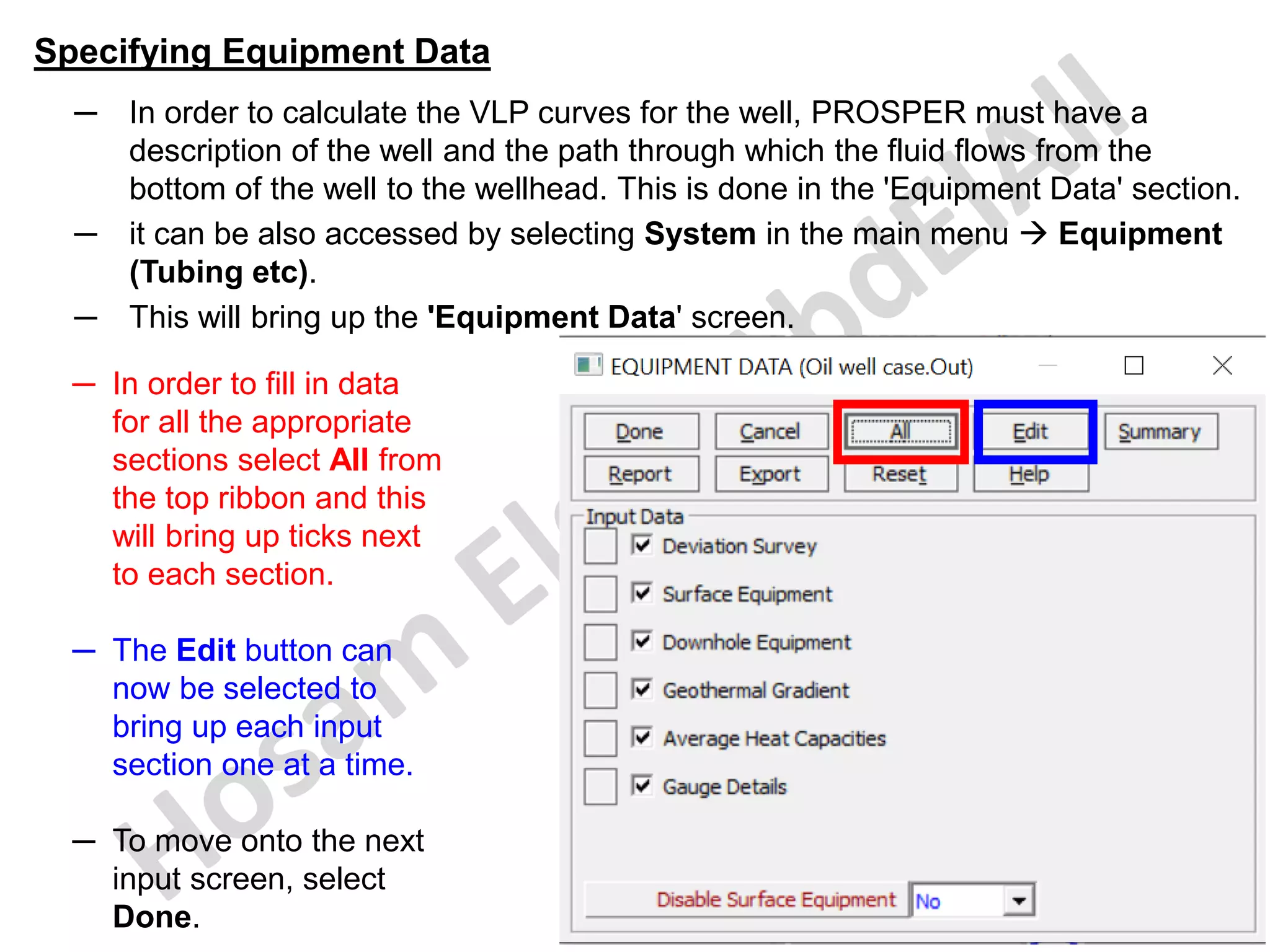

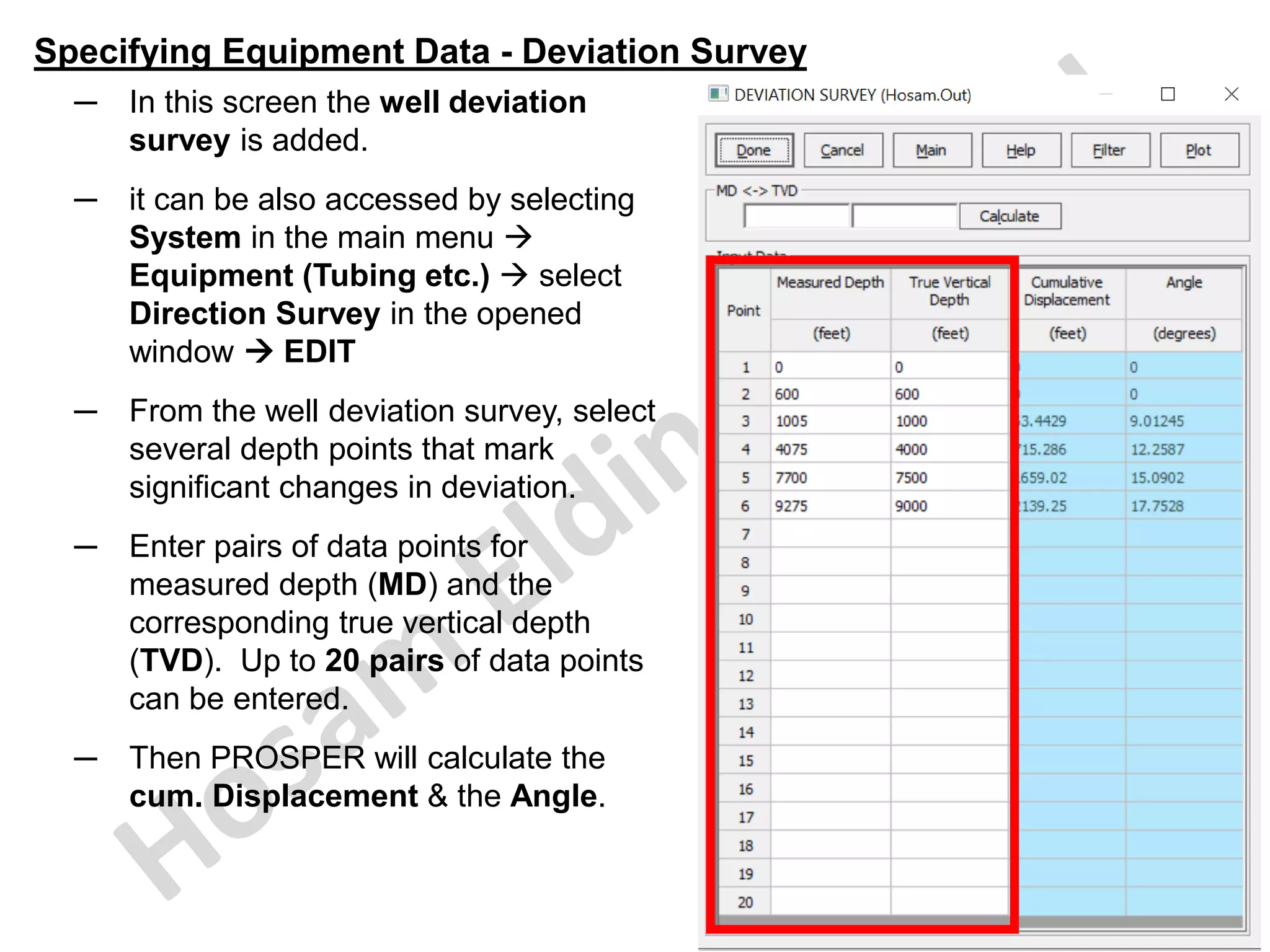

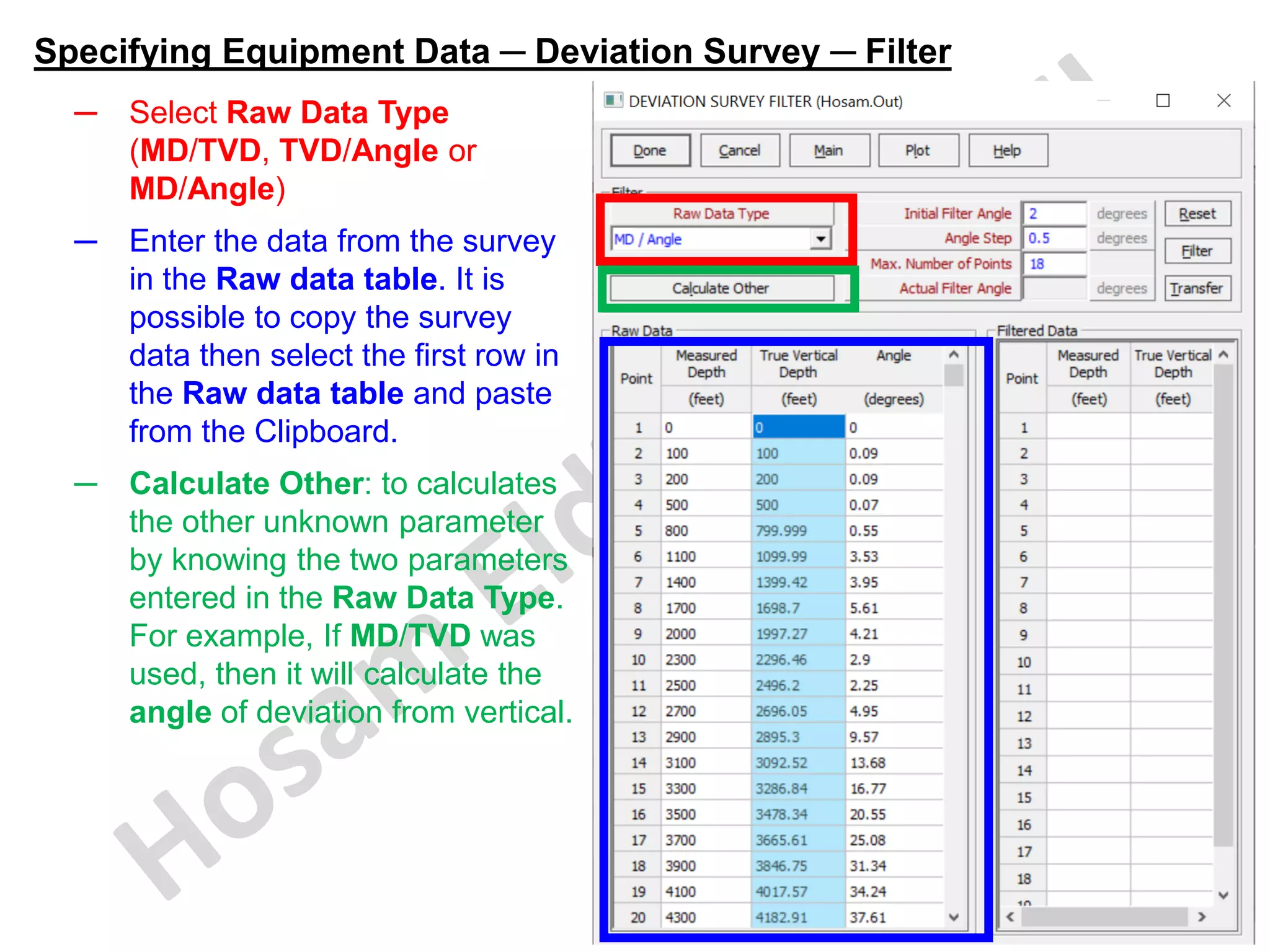

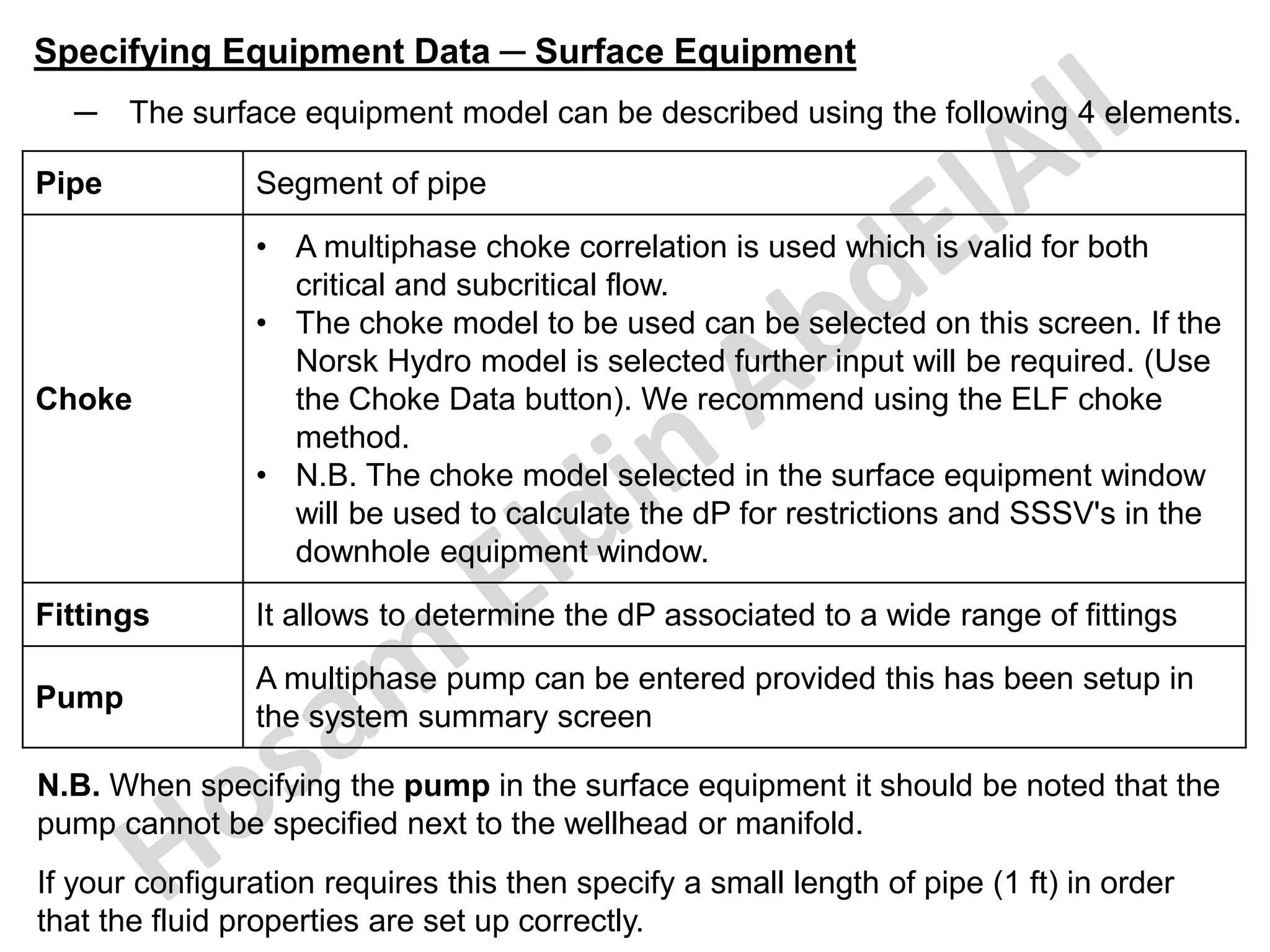

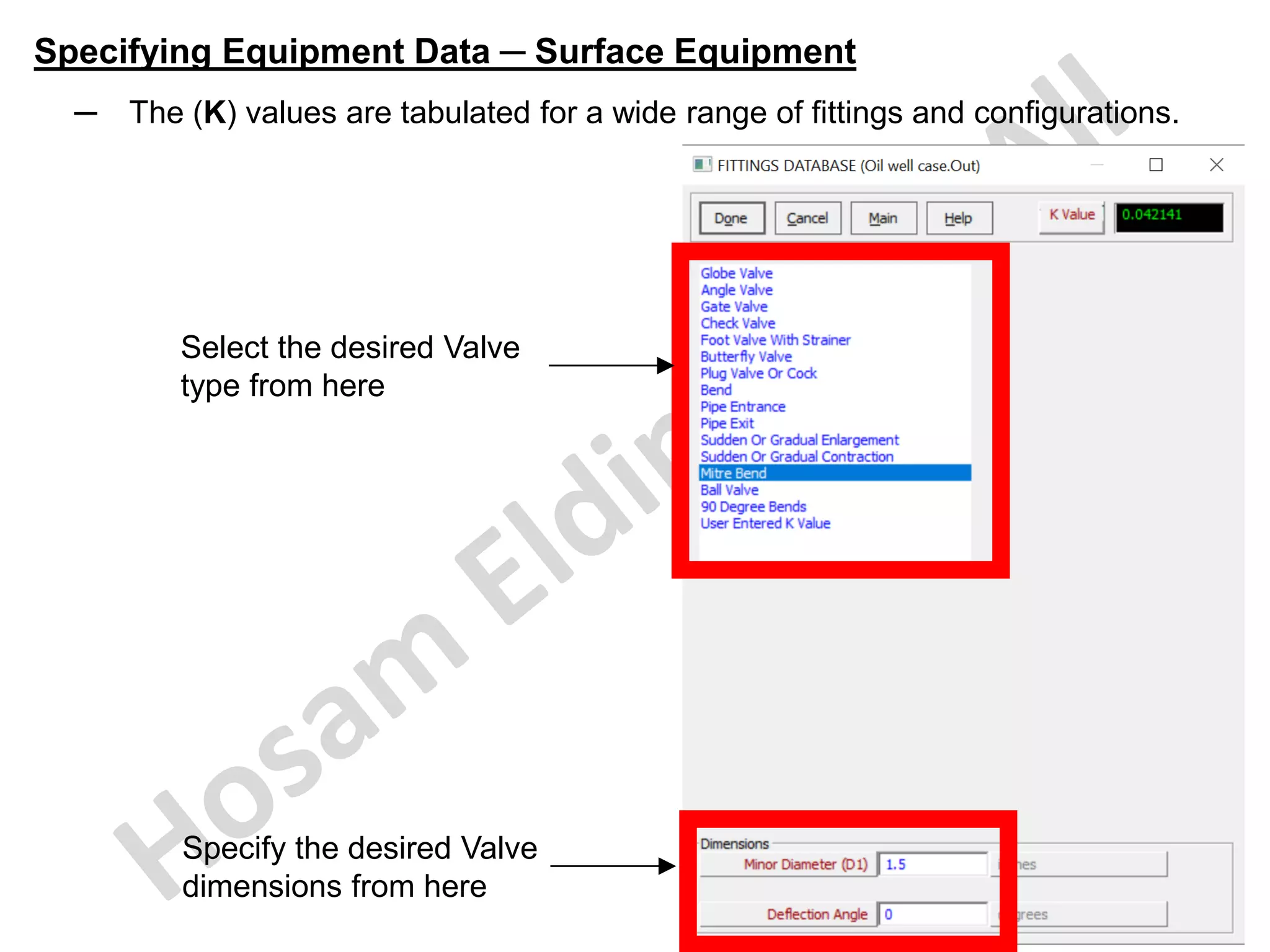

This document provides instructions for building a well model using the PROSPER software. It discusses preparing input data by organizing it in an Excel file with separate sheets for completion, test, and PVT/IPR data. It also covers setting up the model type and fluid properties in PROSPER. PVT data from lab tests should be entered on the PVT input screen and used to calculate fluid properties under changing pressure and temperature conditions through correlation, matching, or direct entry of PVT tables. The overall objective is to accurately simulate well performance and predict production levels.