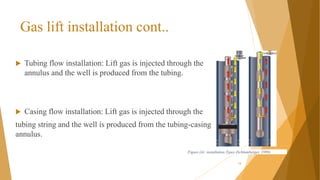

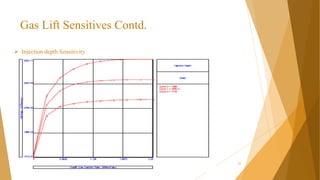

The document discusses the gas lift technique used for artificial lift in petroleum engineering, outlining its methodology, advantages, limitations, and types. It details the project objective of optimizing gas lift system parameters through modeling and simulation using the Prosper software. Additionally, the document covers gas lift installation processes, sensitivities affecting performance, and concludes with recommendations for effective gas lift system operation.