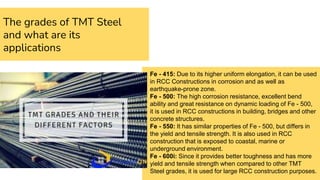

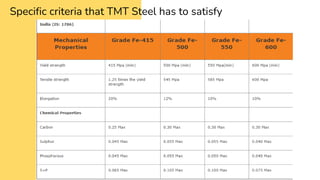

This presentation discusses TMT bars and their grades. TMT bars are steel bars manufactured through a thermo-mechanical treatment process that combines mechanical and thermal processes. There are four main grades of TMT bars used in India - Fe-415, Fe-500, Fe-550, and Fe-600i - which indicate the level of stress required to deform the bars. Each grade has different properties making it suitable for different construction applications, such as Fe-415 being used in earthquake-prone areas and Fe-600i for large constructions. The presentation explains the properties, applications, and manufacturing criteria of the different TMT bar grades.