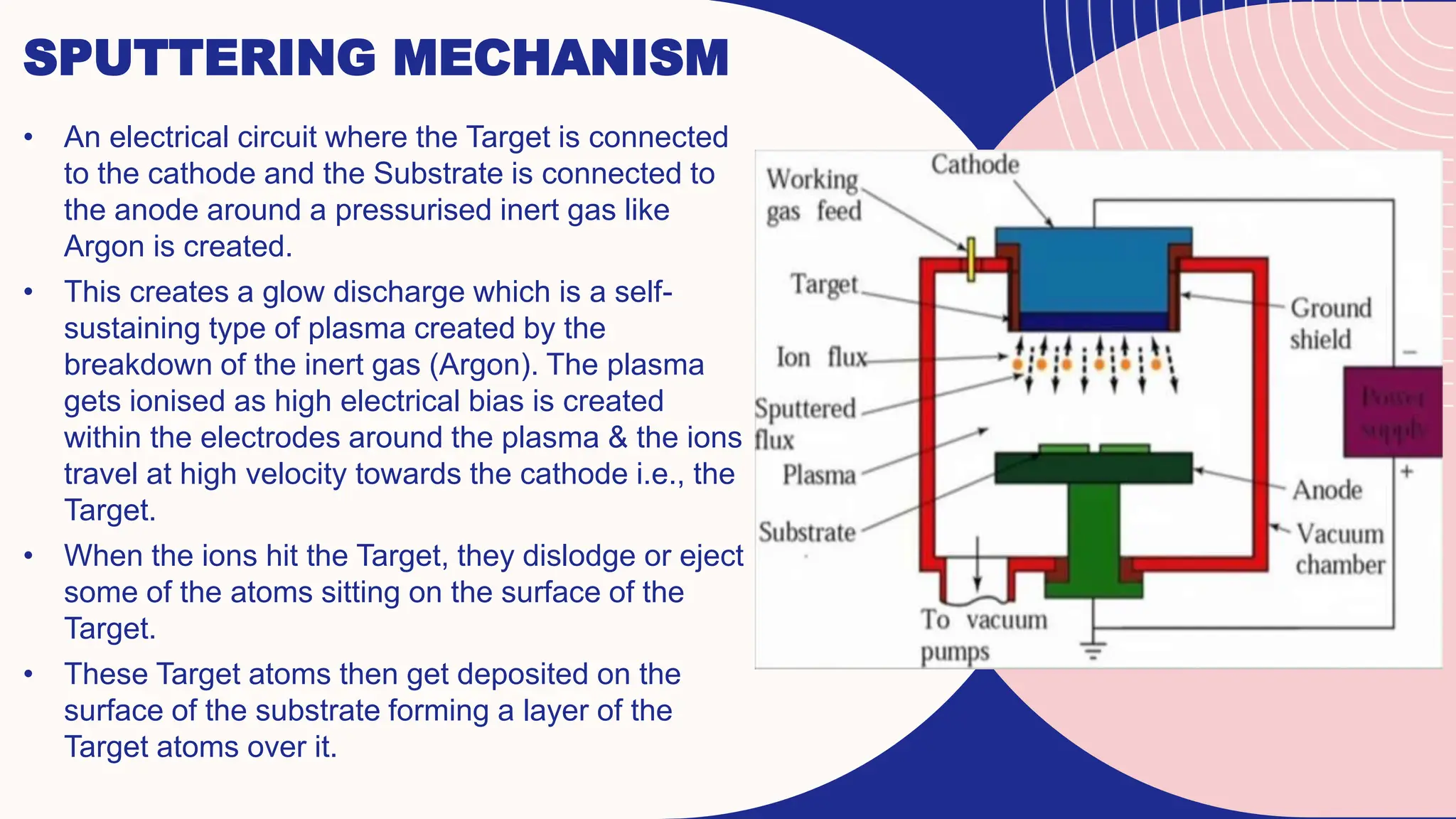

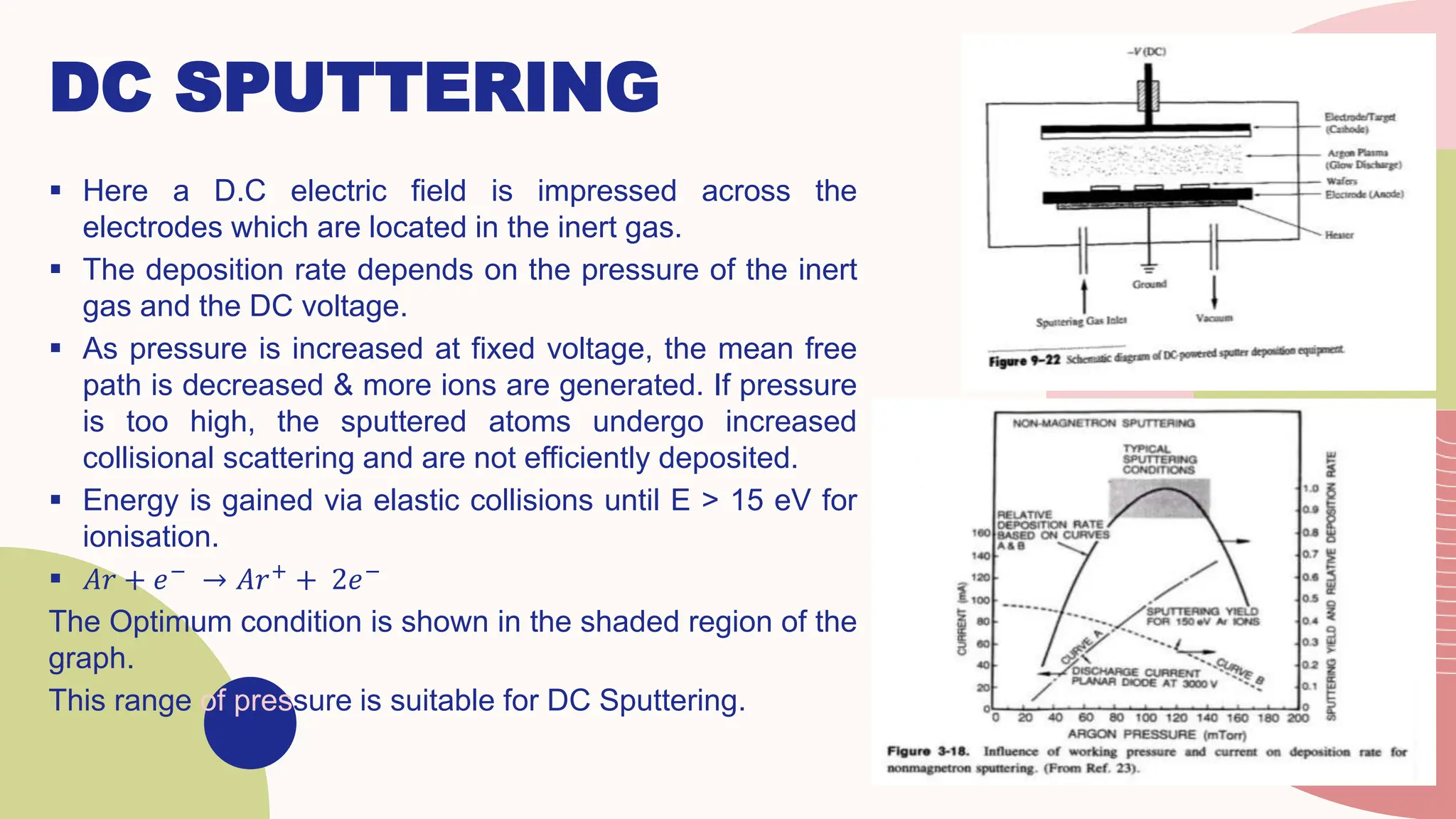

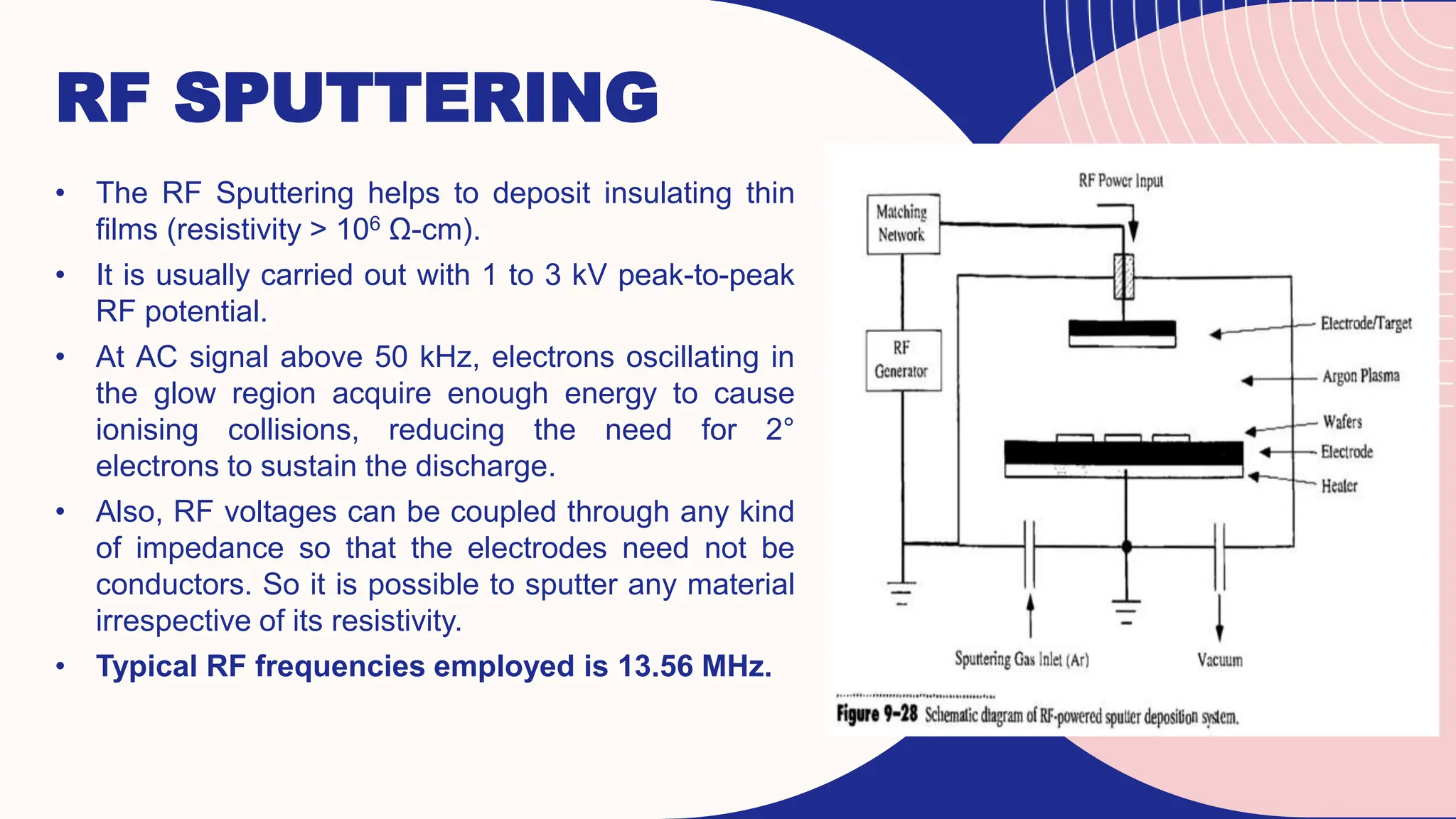

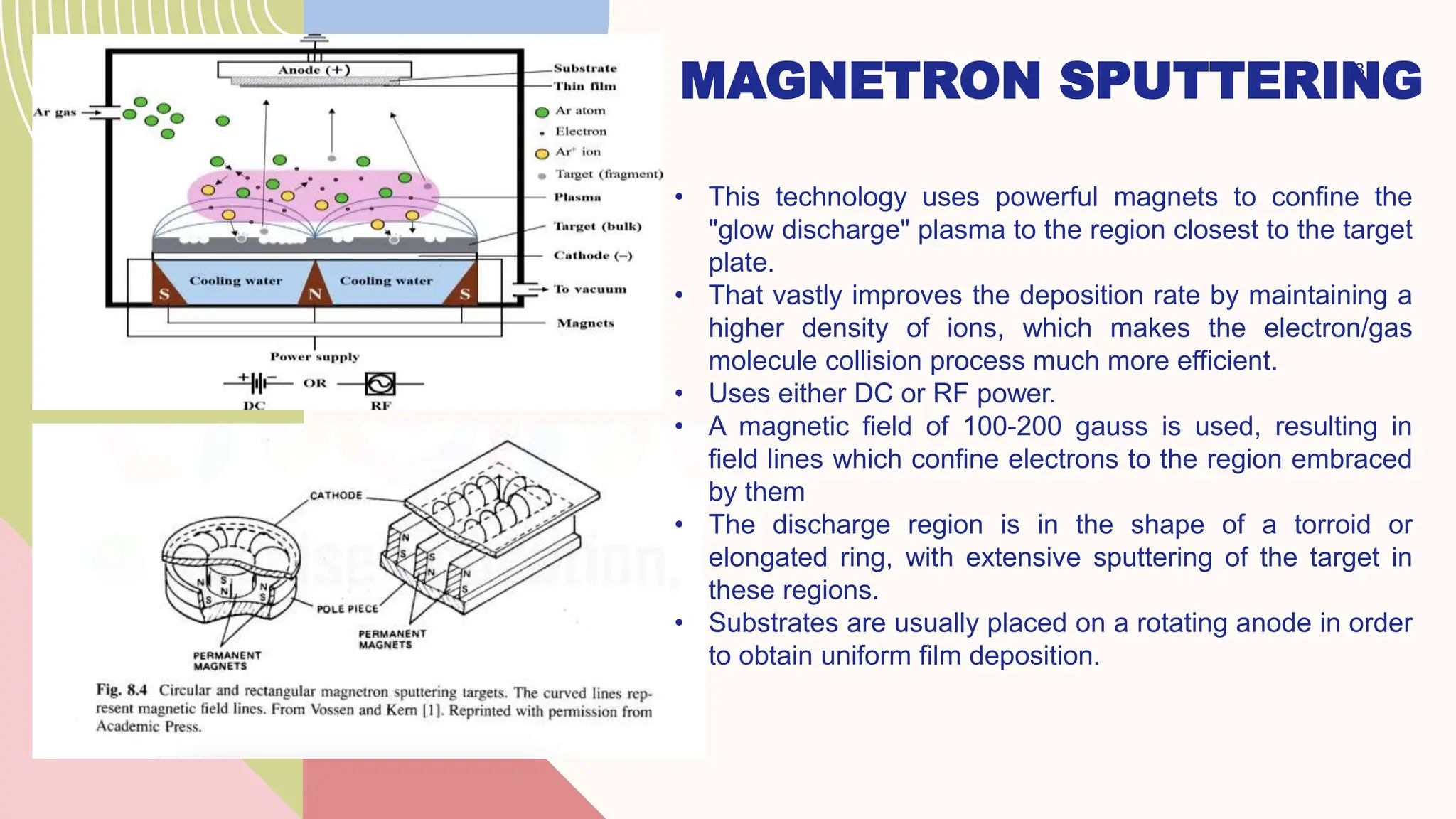

This document provides an overview of sputtering, a physical vapor deposition technique where high-energy ions bombard a target material, dislodging atoms that then deposit as a thin film on a substrate. It describes the basic sputtering mechanism and factors that influence sputter yield. Various sputtering techniques are covered, including DC, RF, magnetron, reactive, and bias sputtering. Advantages of sputtering include high deposition rates and excellent adhesion, while disadvantages include high capital costs and potential for damage or impurity incorporation.