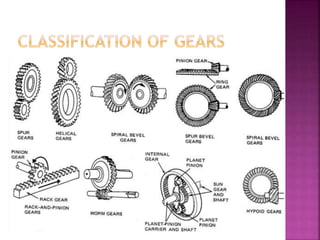

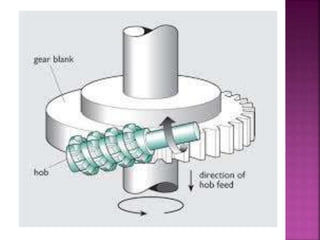

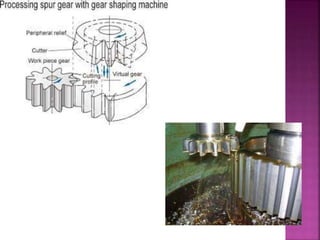

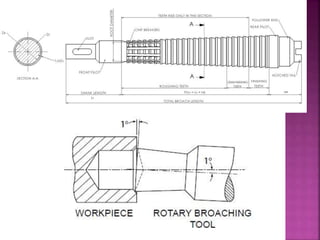

Spur gears transmit power between two parallel shafts by meshing teeth without slip. The smaller gear is called the pinion and the larger is called the gear. Spur gears have teeth parallel to their axis. They are simple, inexpensive to manufacture, efficient, and precise. Common materials used for spur gears include plastic, brass, steel, and aluminum. Spur gears can be manufactured through processes like hobbing, shaping, and broaching. Hobbing involves sequential cuts by a cutting tool in the shape of a gear to form teeth. Broaching uses a toothed broach tool to cut teeth in one pass, making it efficient. Spur gears are used widely in devices to transmit motion between parallel shafts.