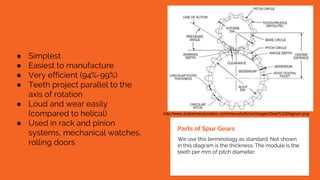

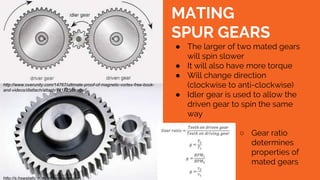

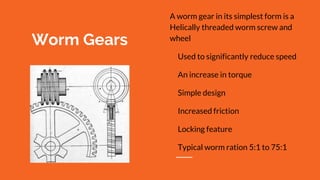

The document discusses different types of gears that could be used to build a gearbox, including spur gears, helical gears, worm gears, and bevel gears. It analyzes the advantages and disadvantages of each type of gear and their feasibility for a semester-long student project to build a gearbox out of acrylic. The document concludes that spur gears would be the most suitable choice for the project due to their simplicity, ease of manufacturing from acrylic sheets using a laser cutter, and efficiency despite being louder and wearing more easily than other gear types.