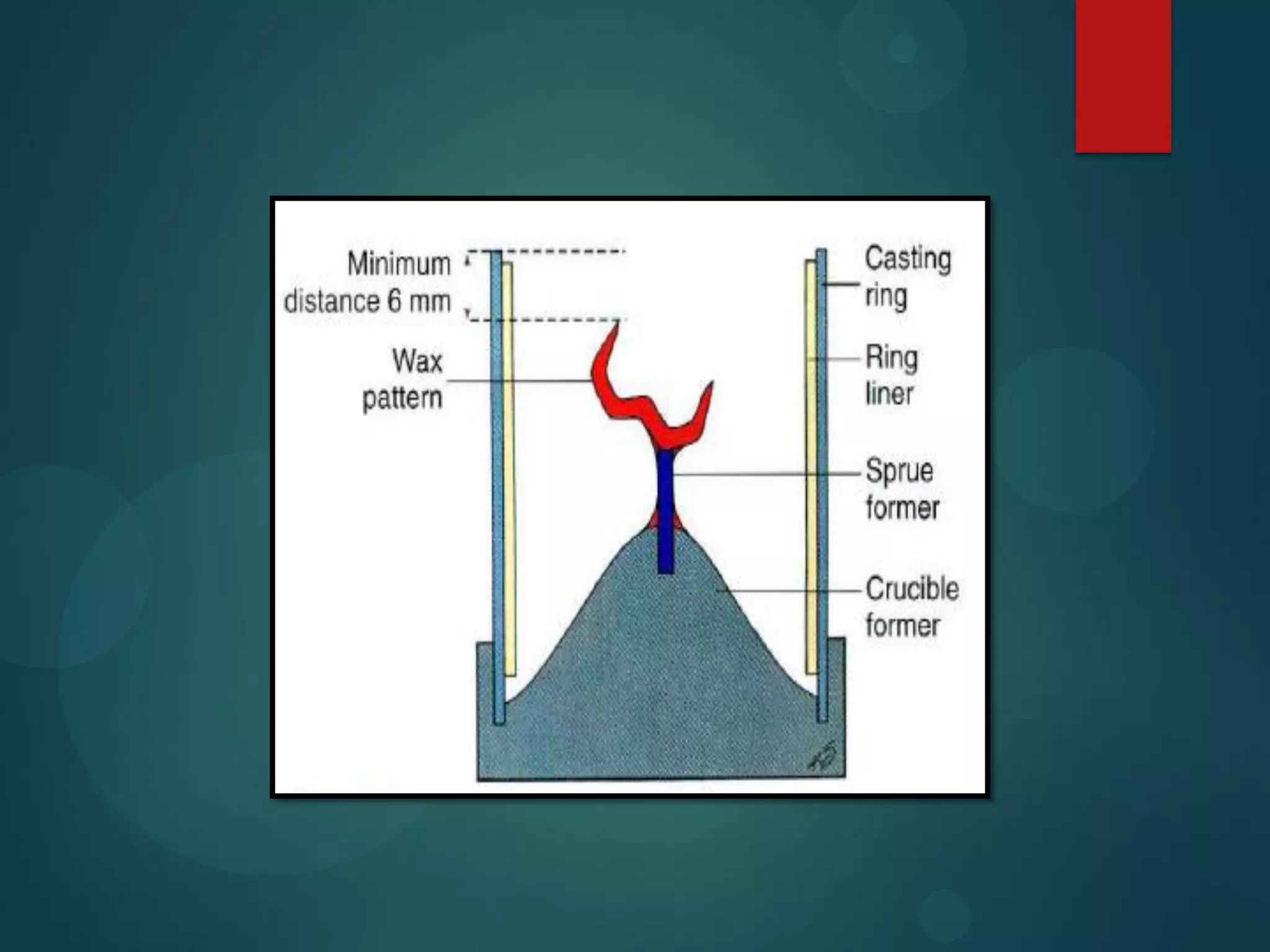

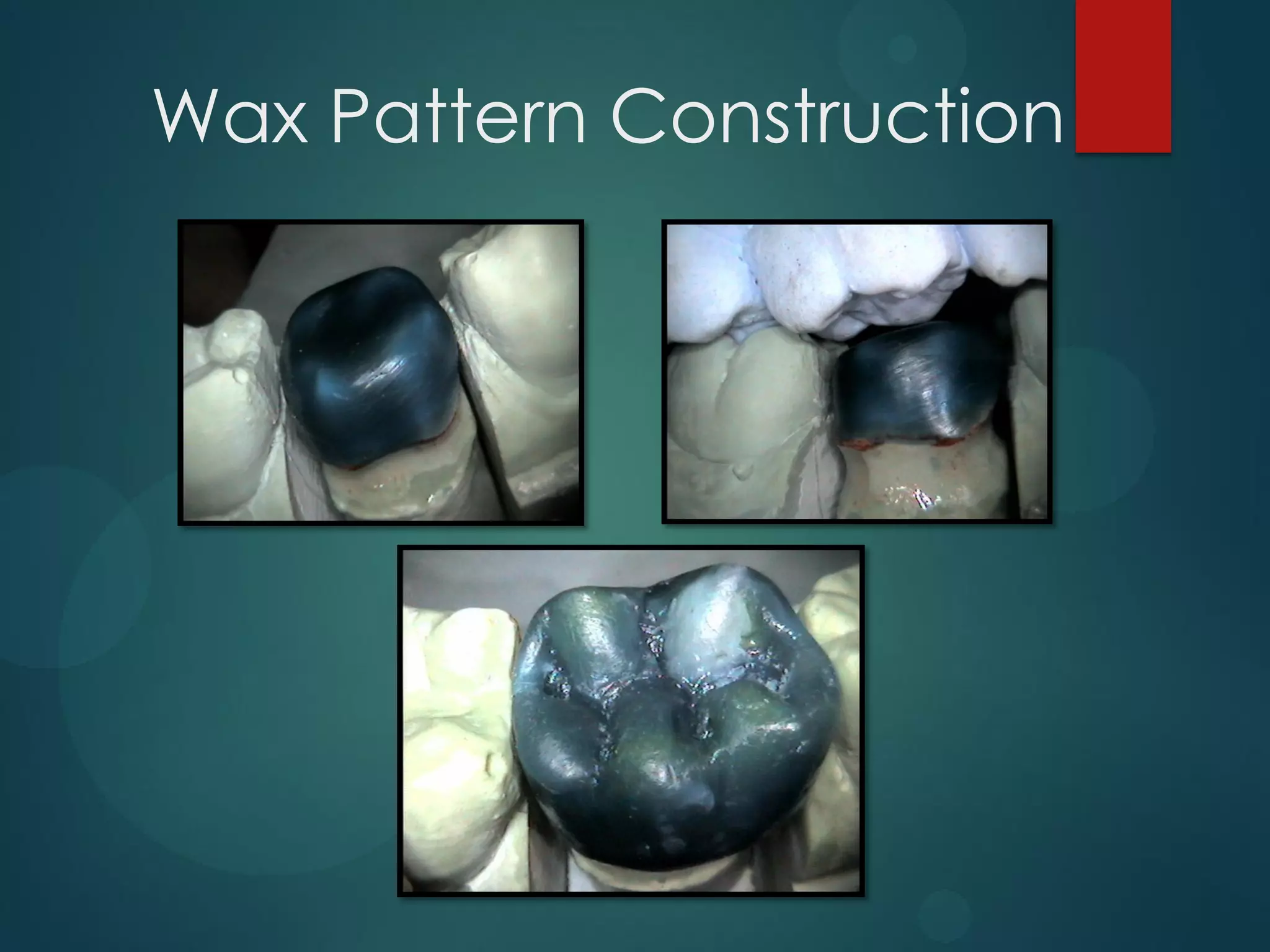

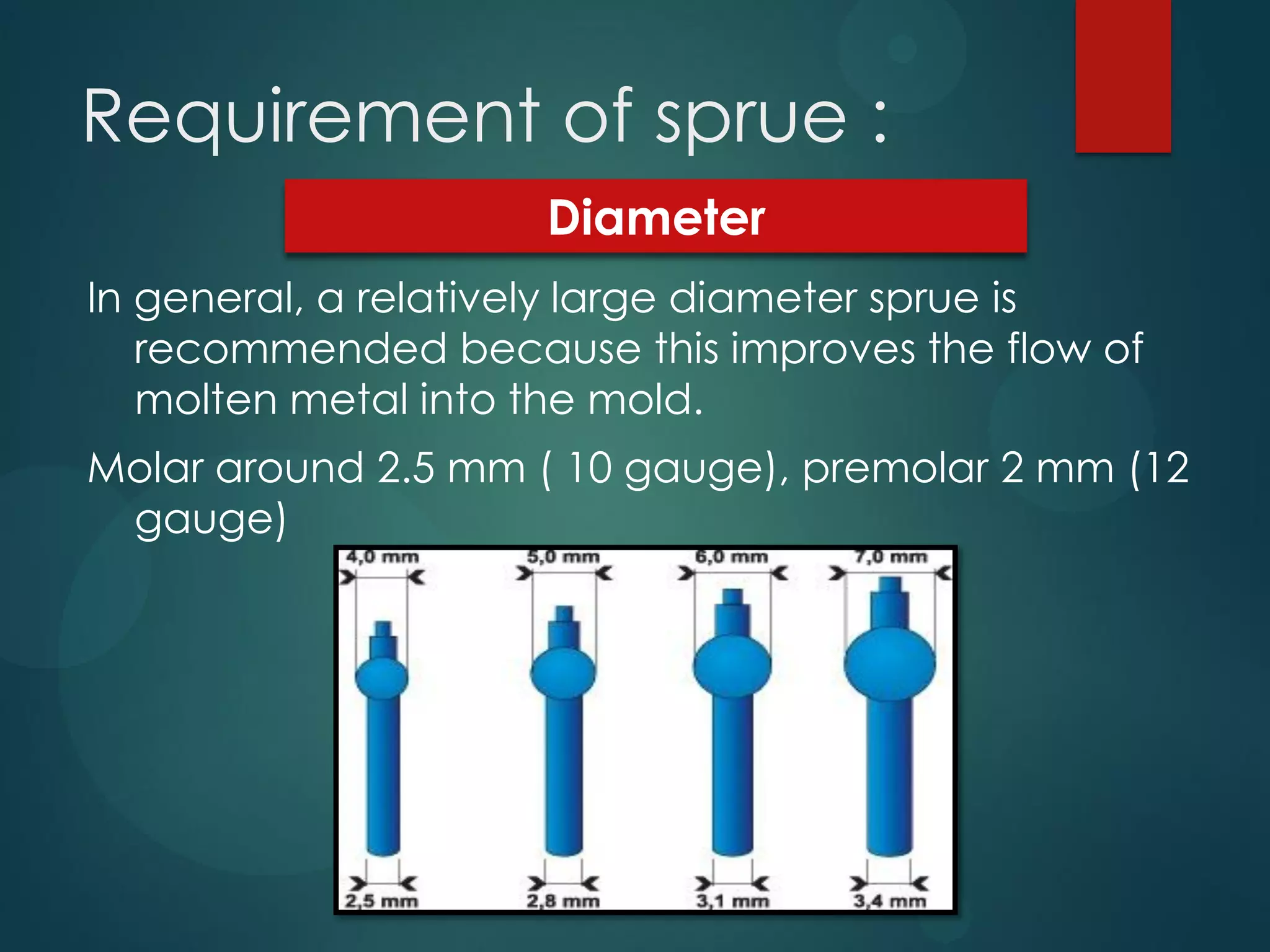

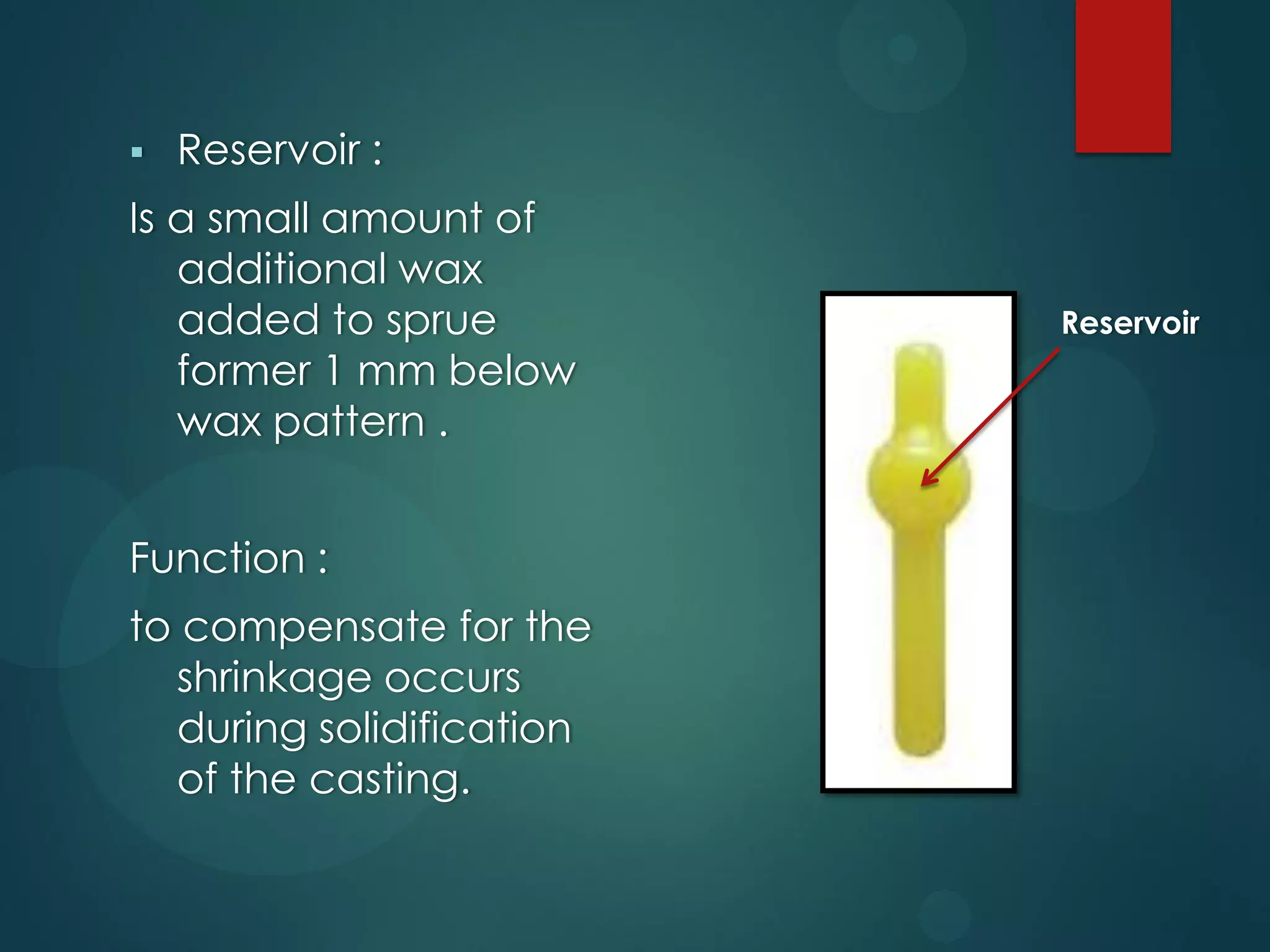

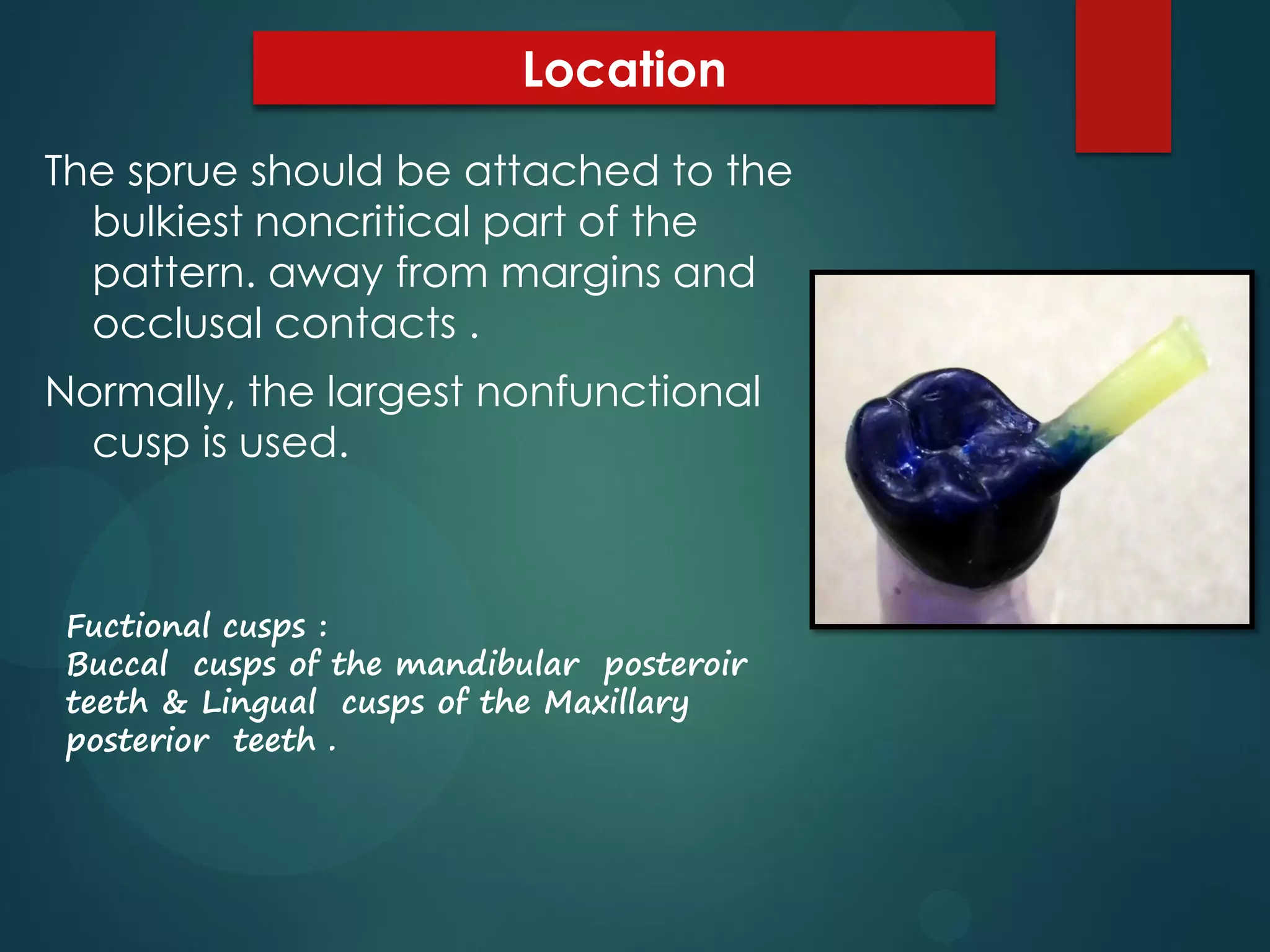

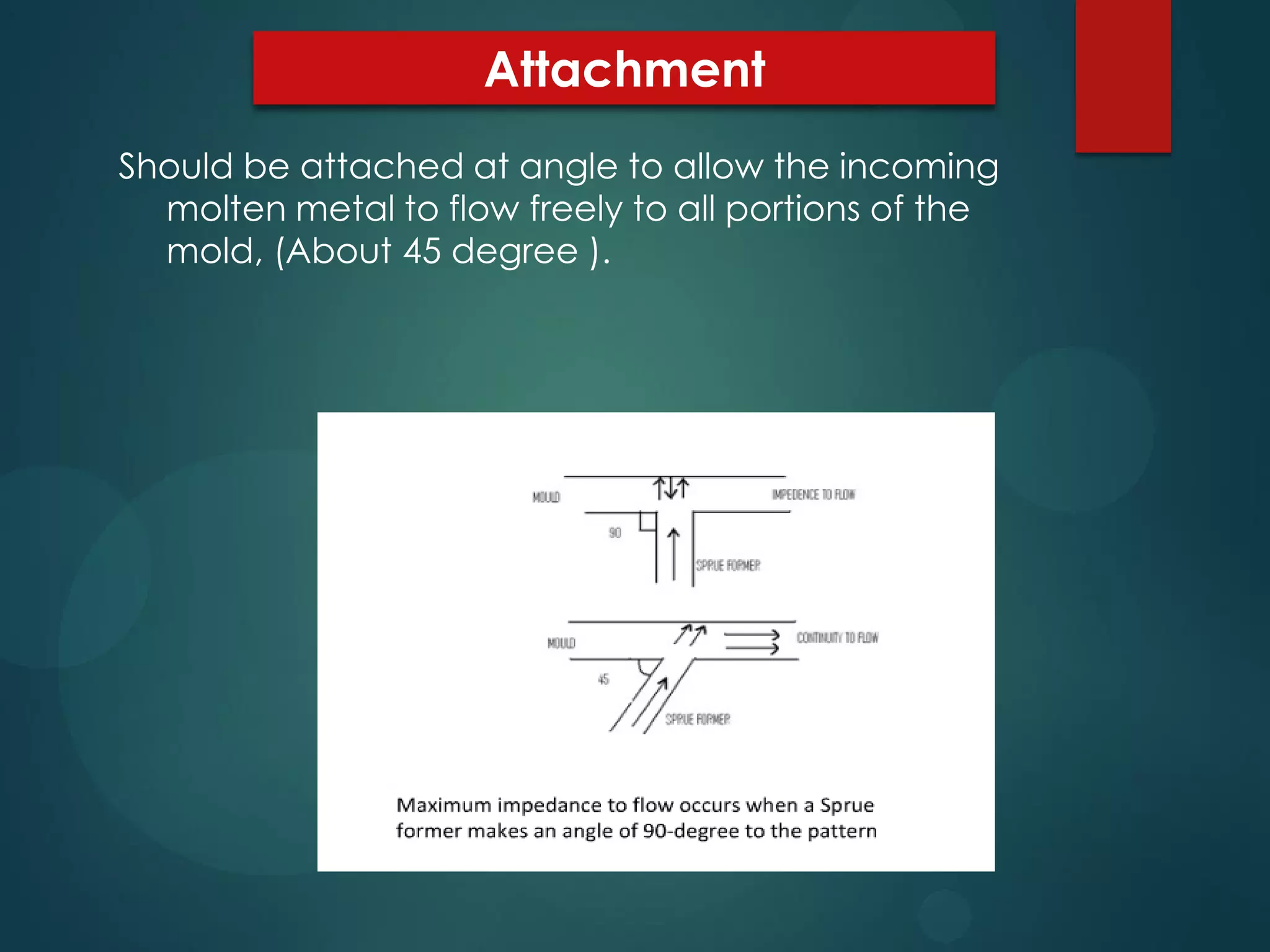

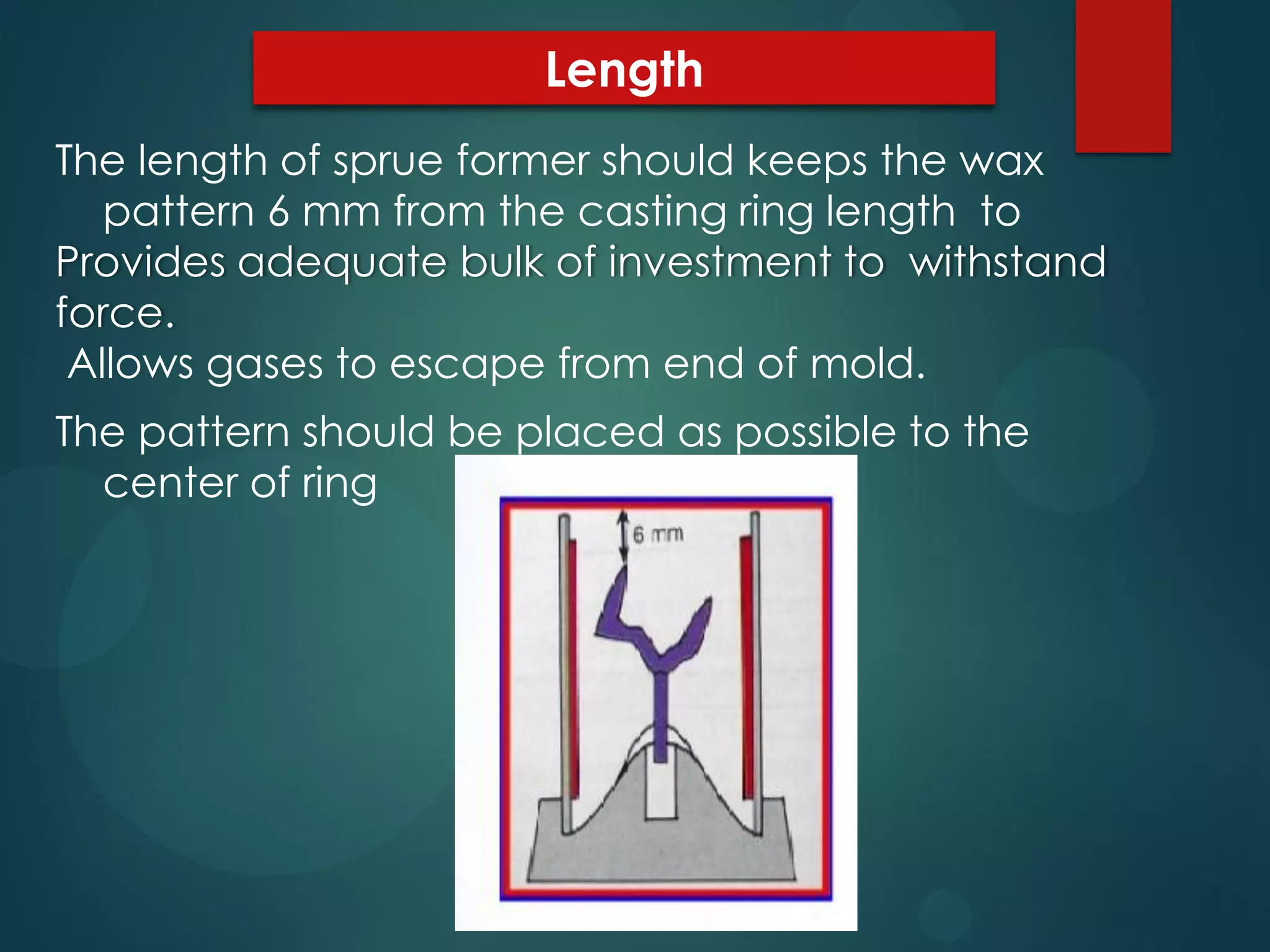

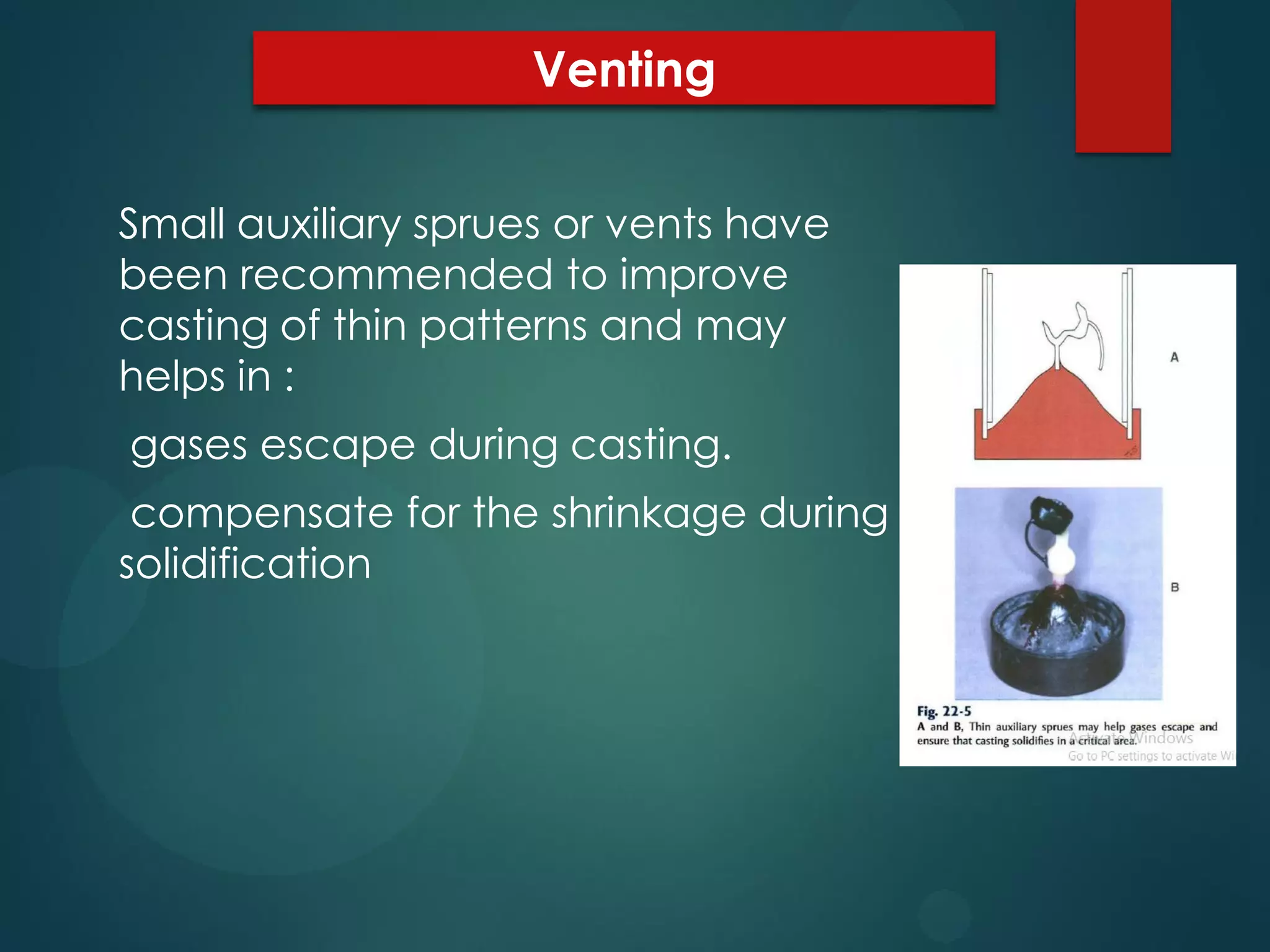

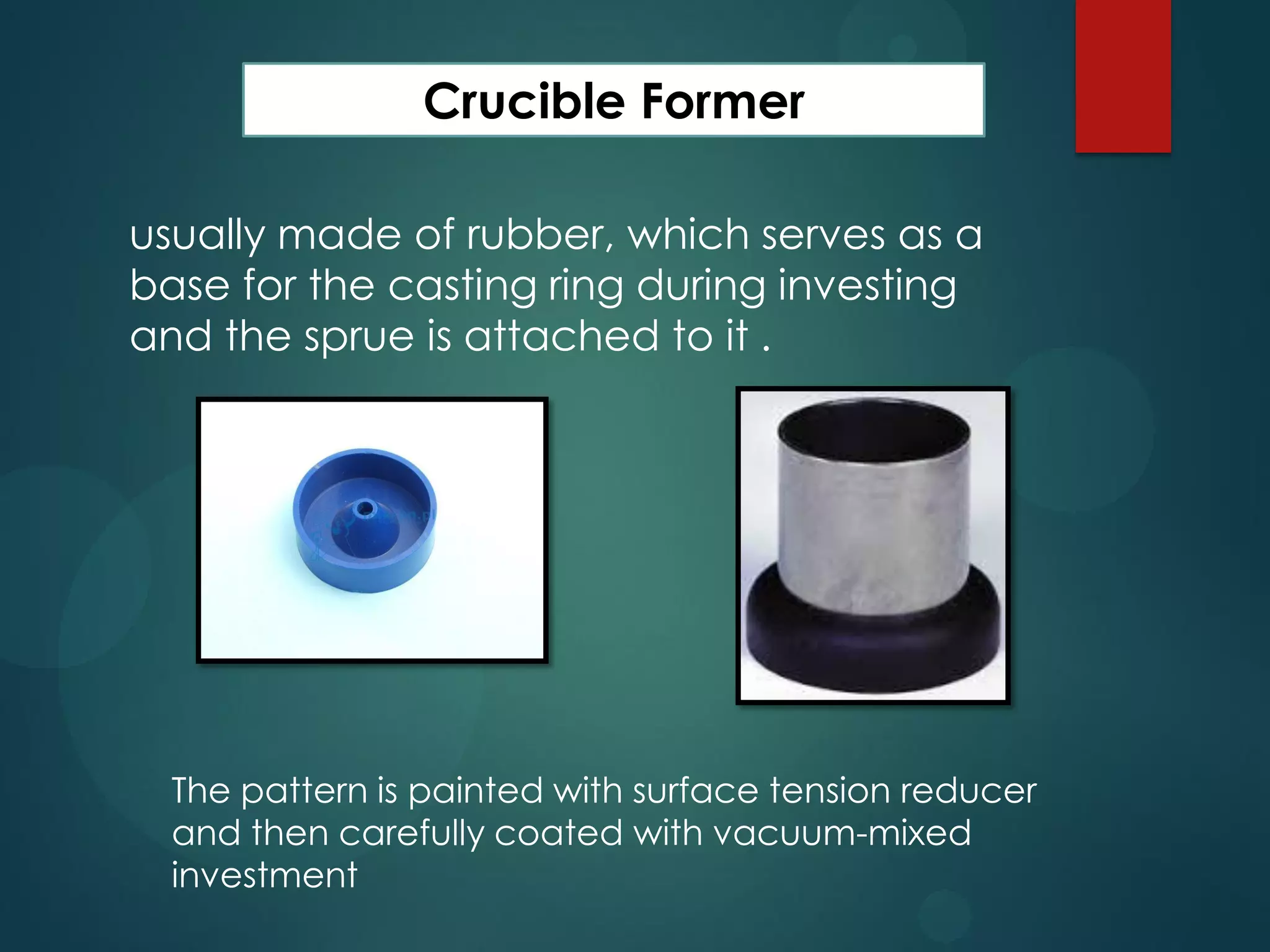

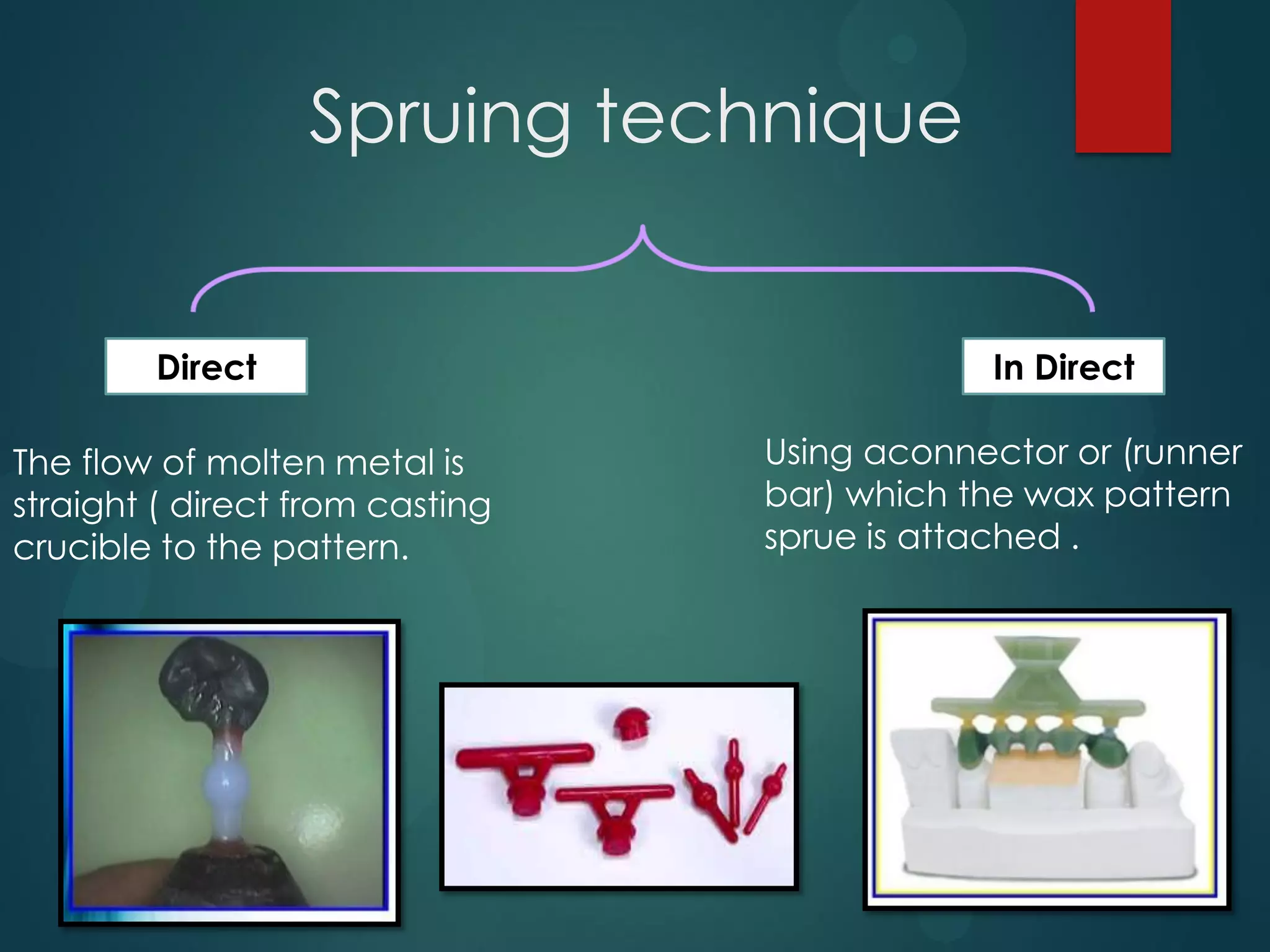

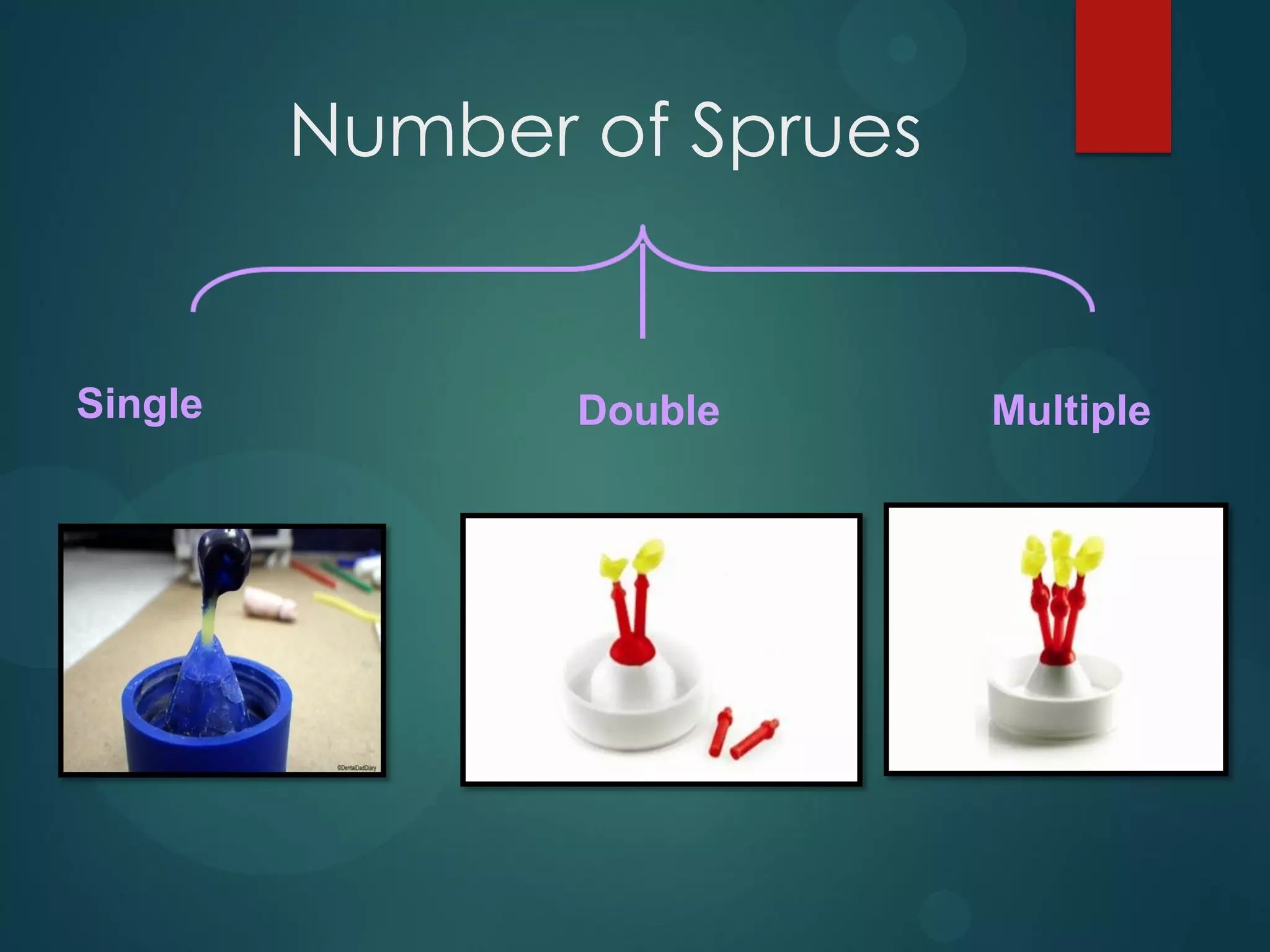

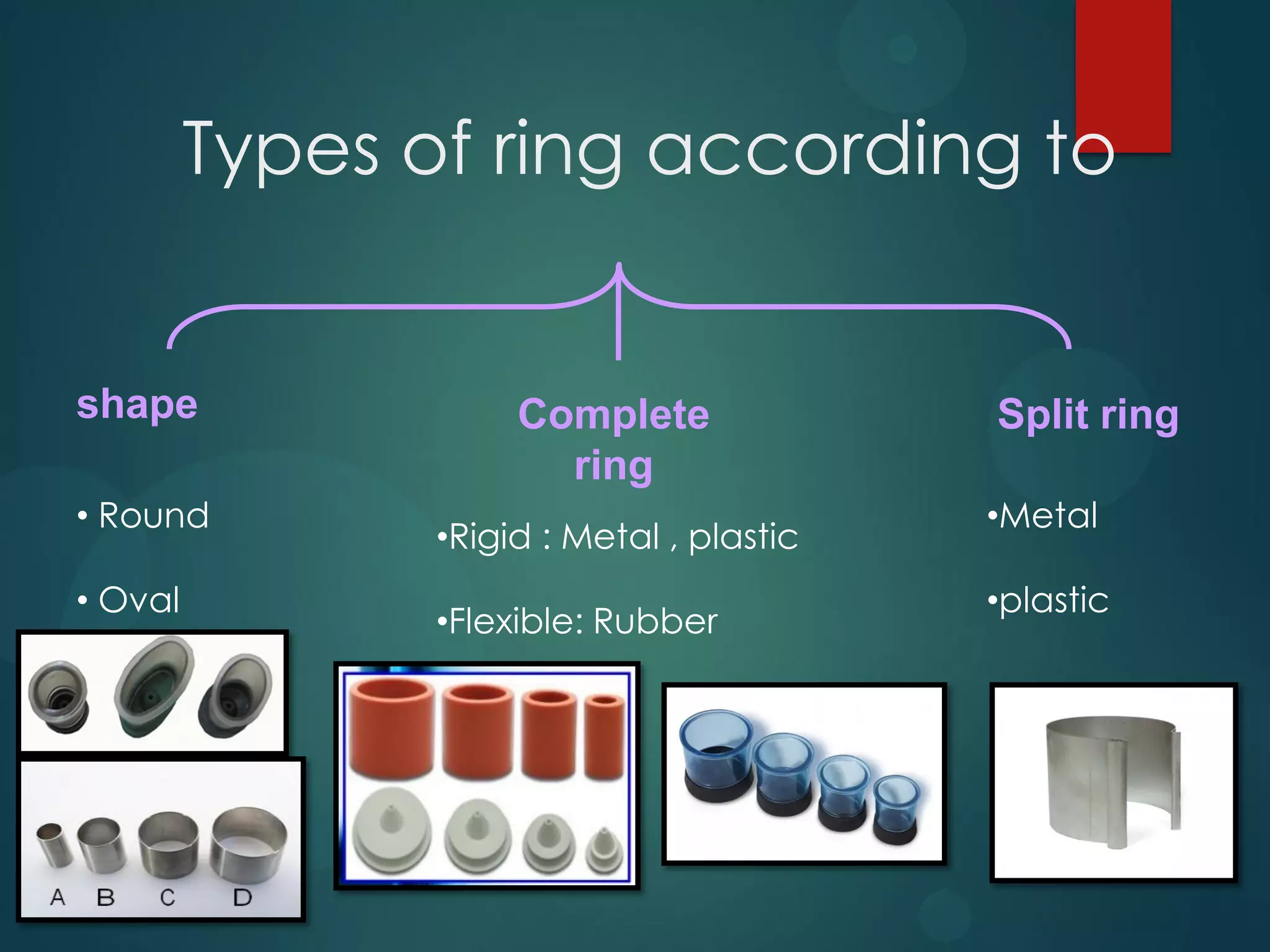

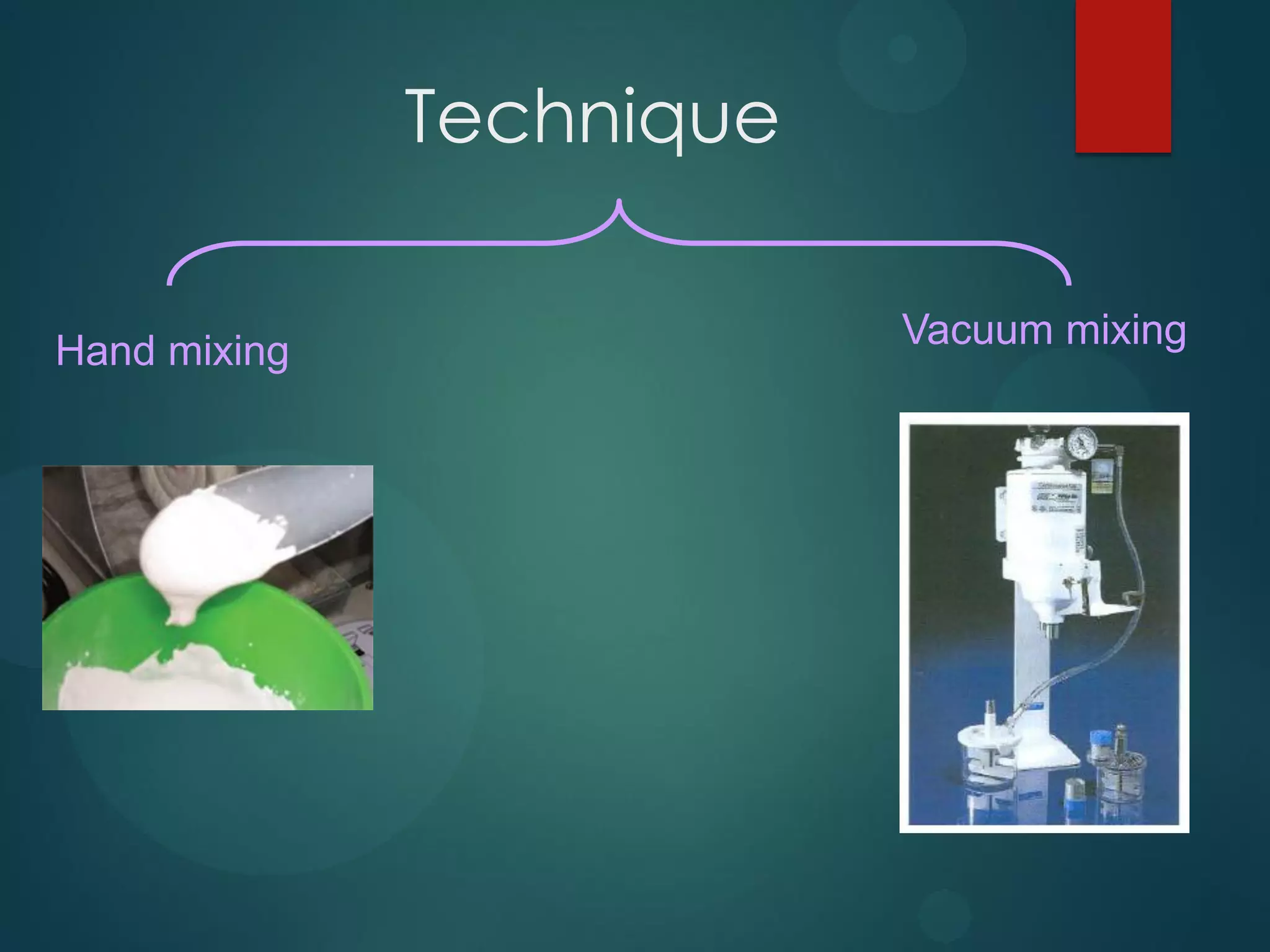

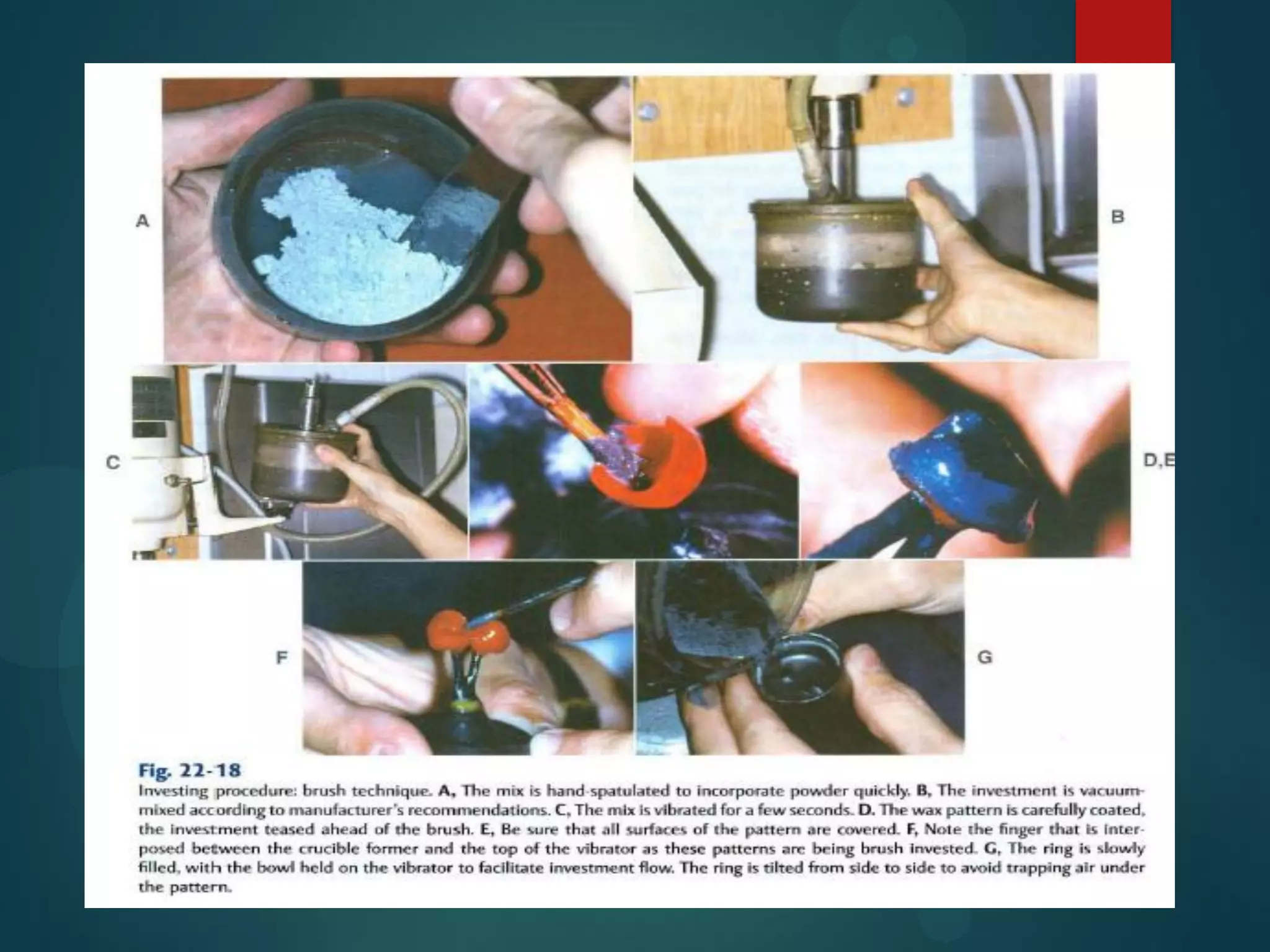

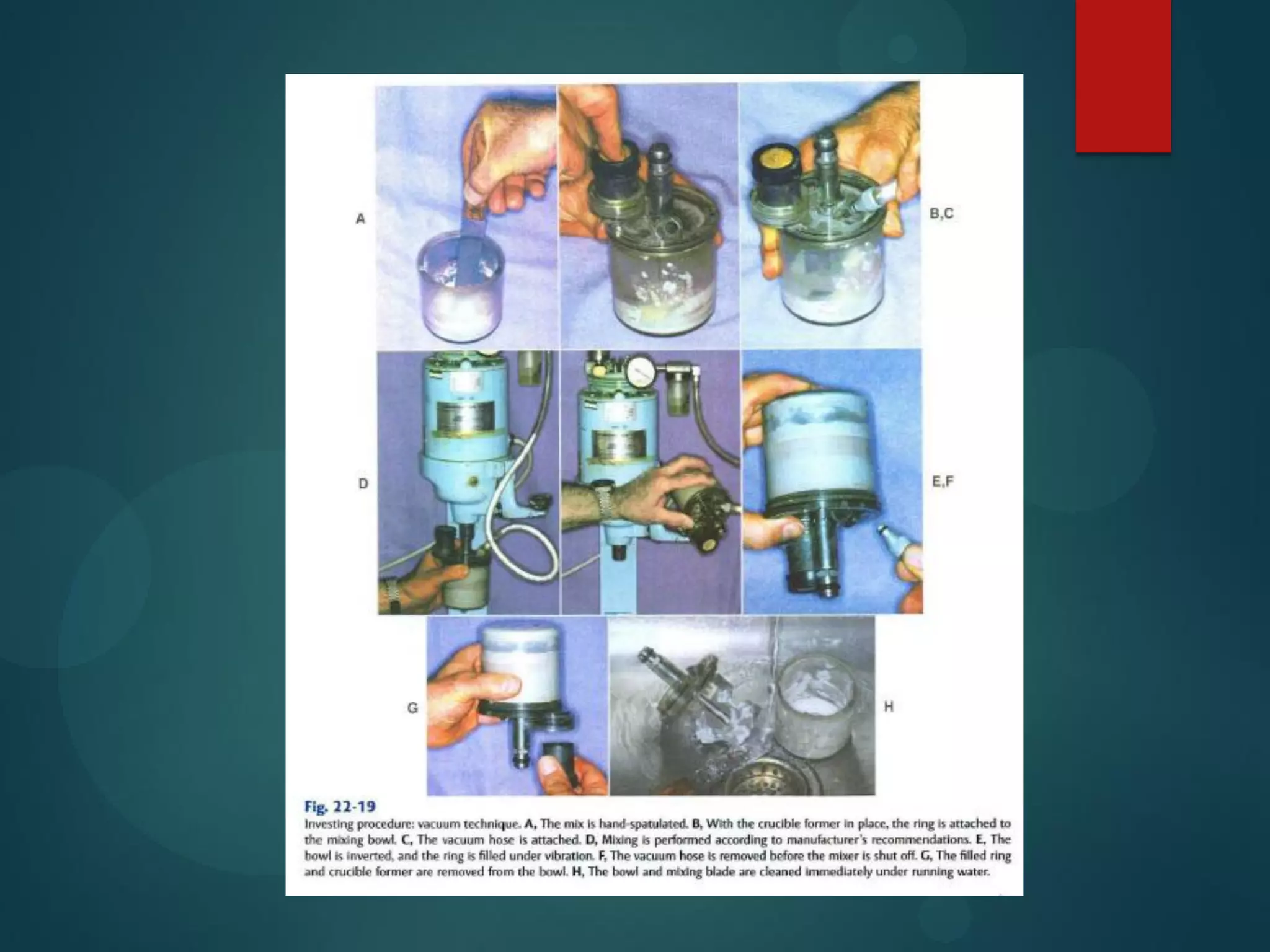

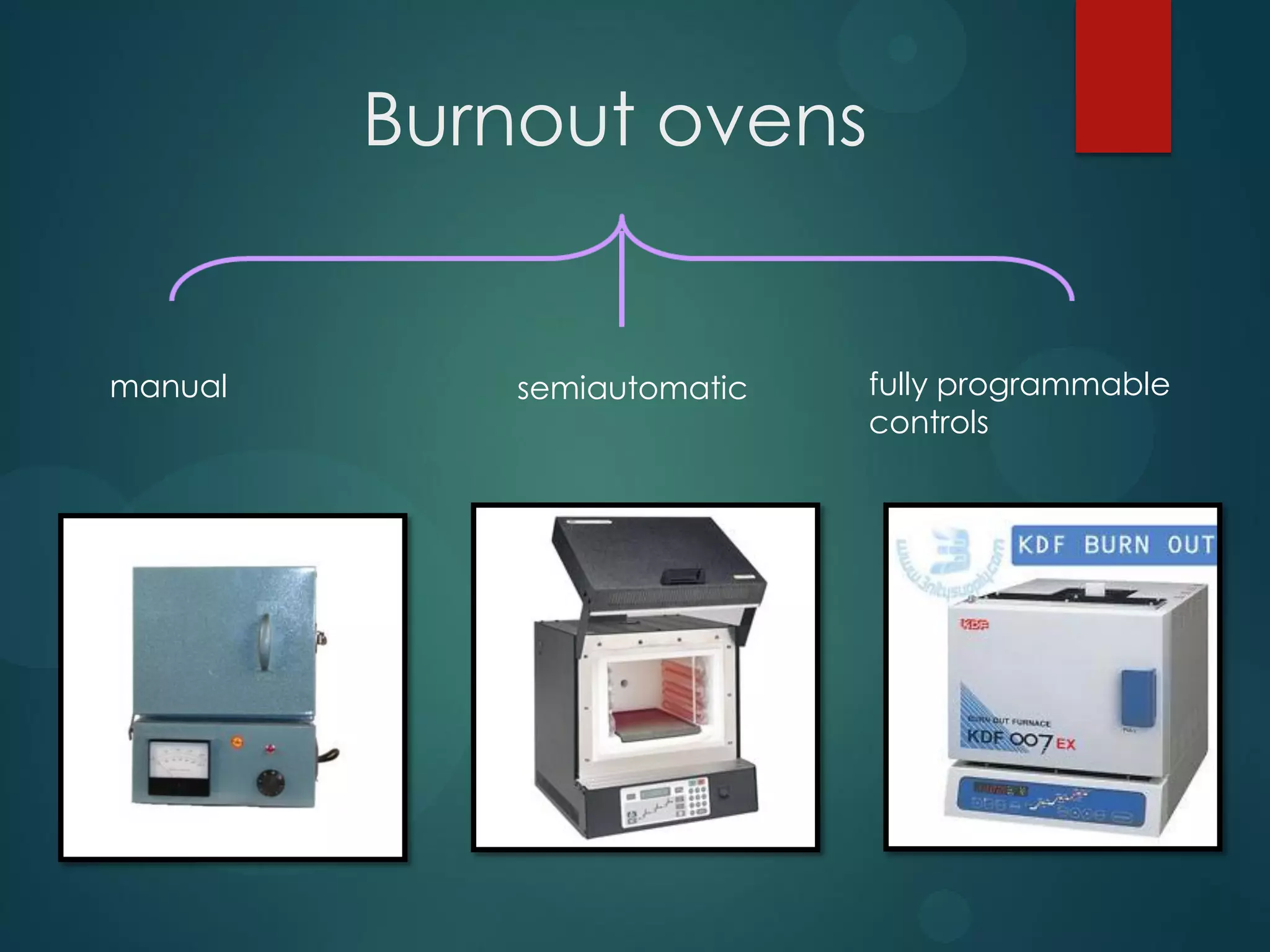

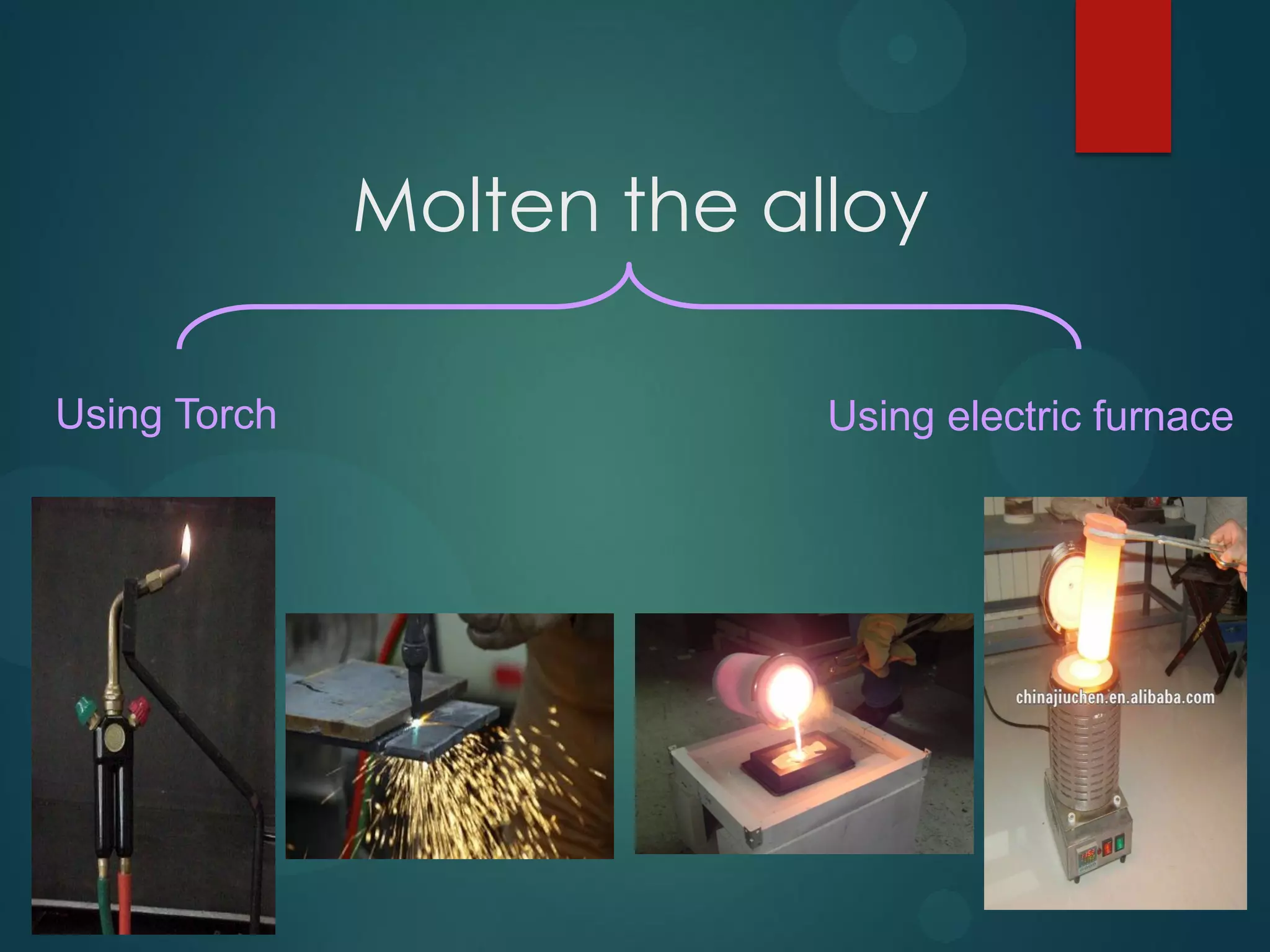

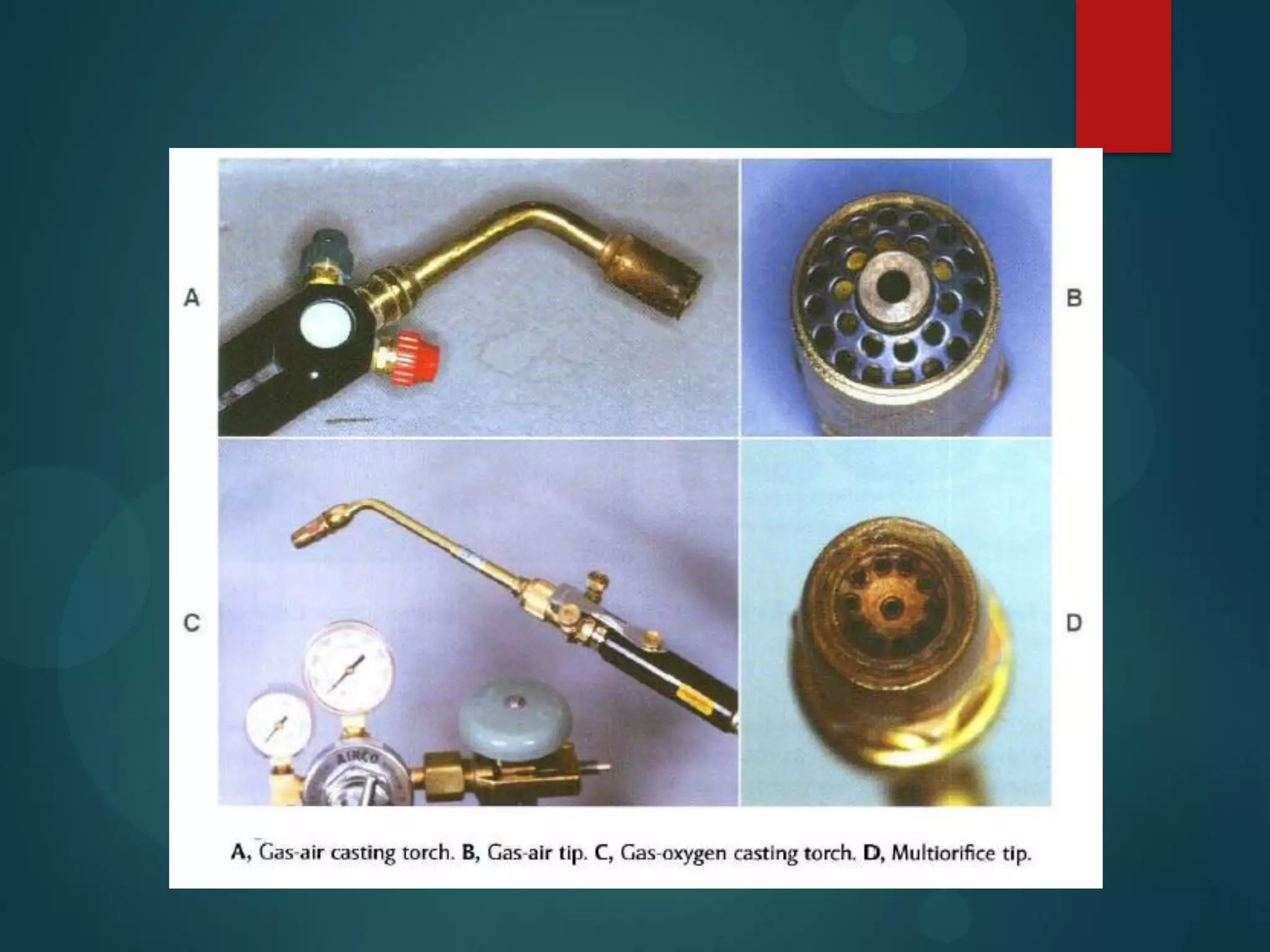

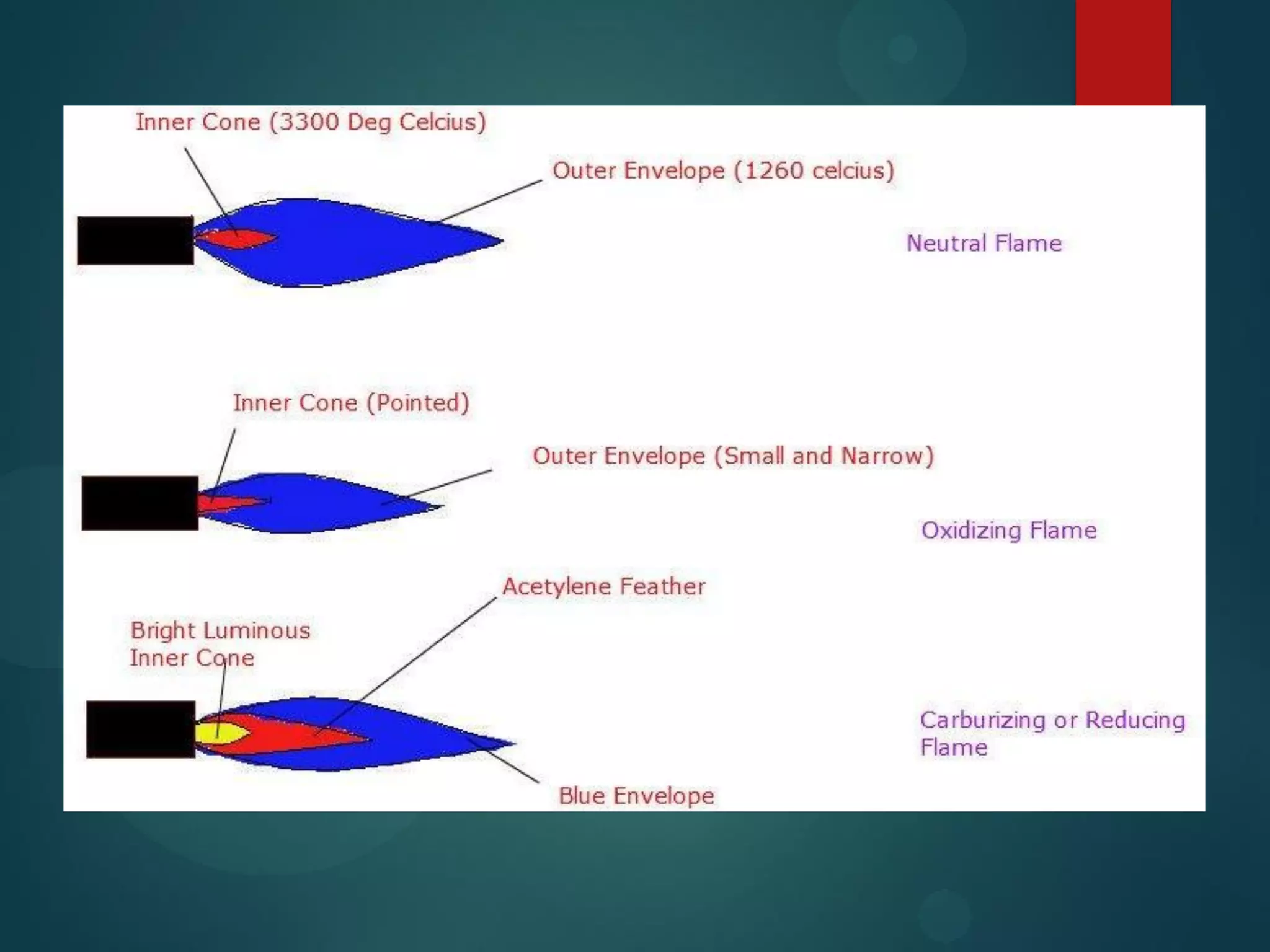

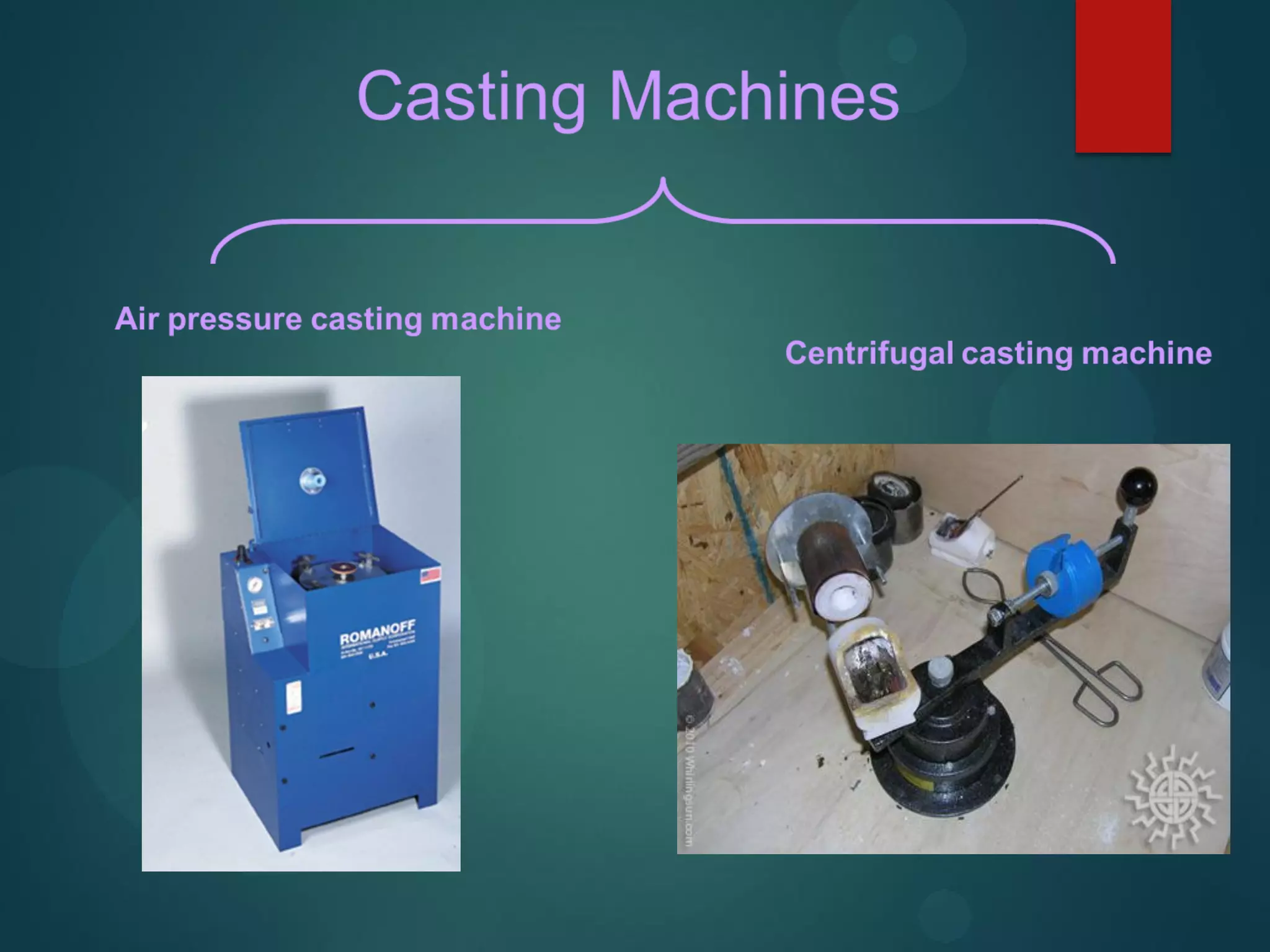

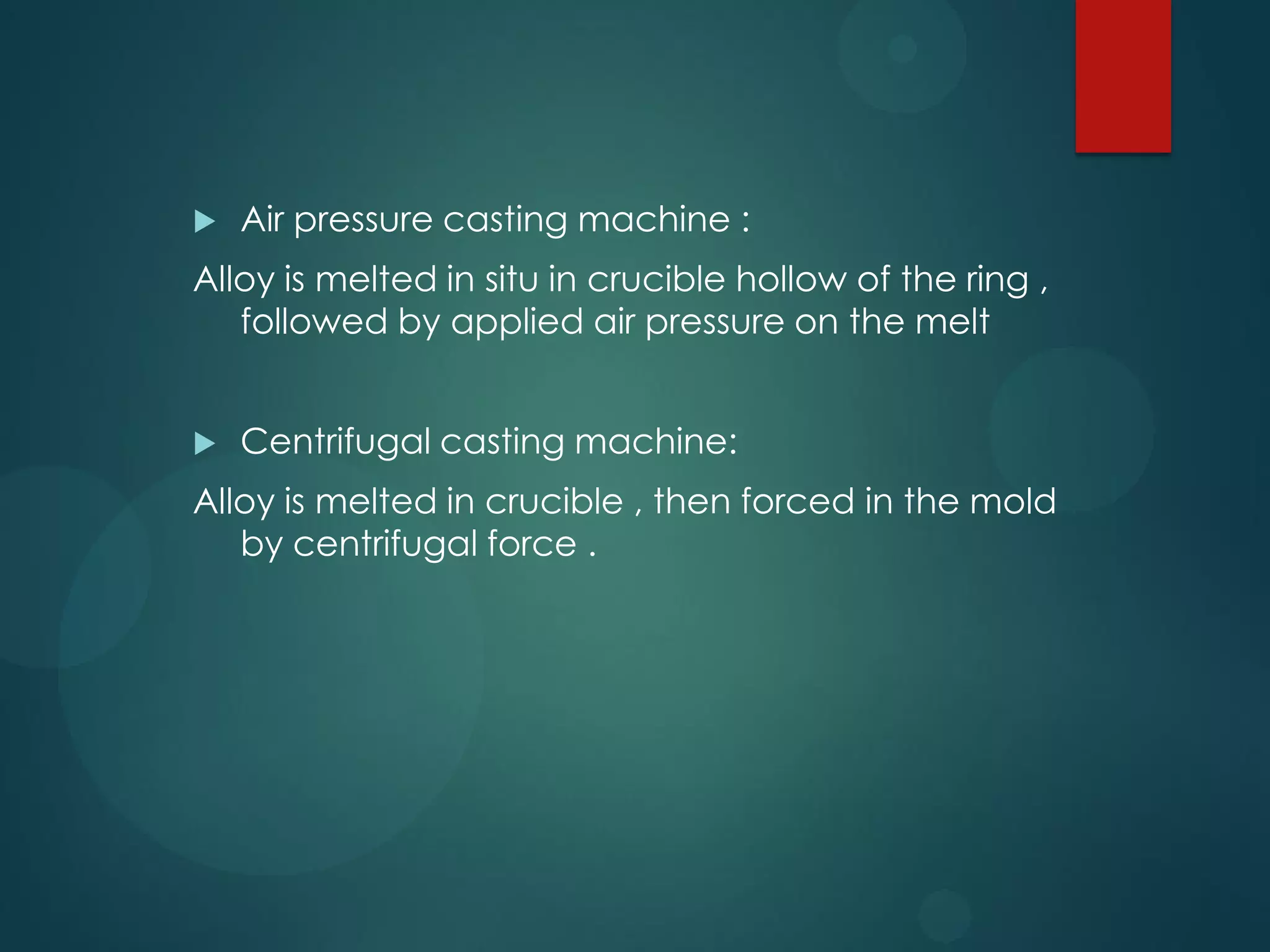

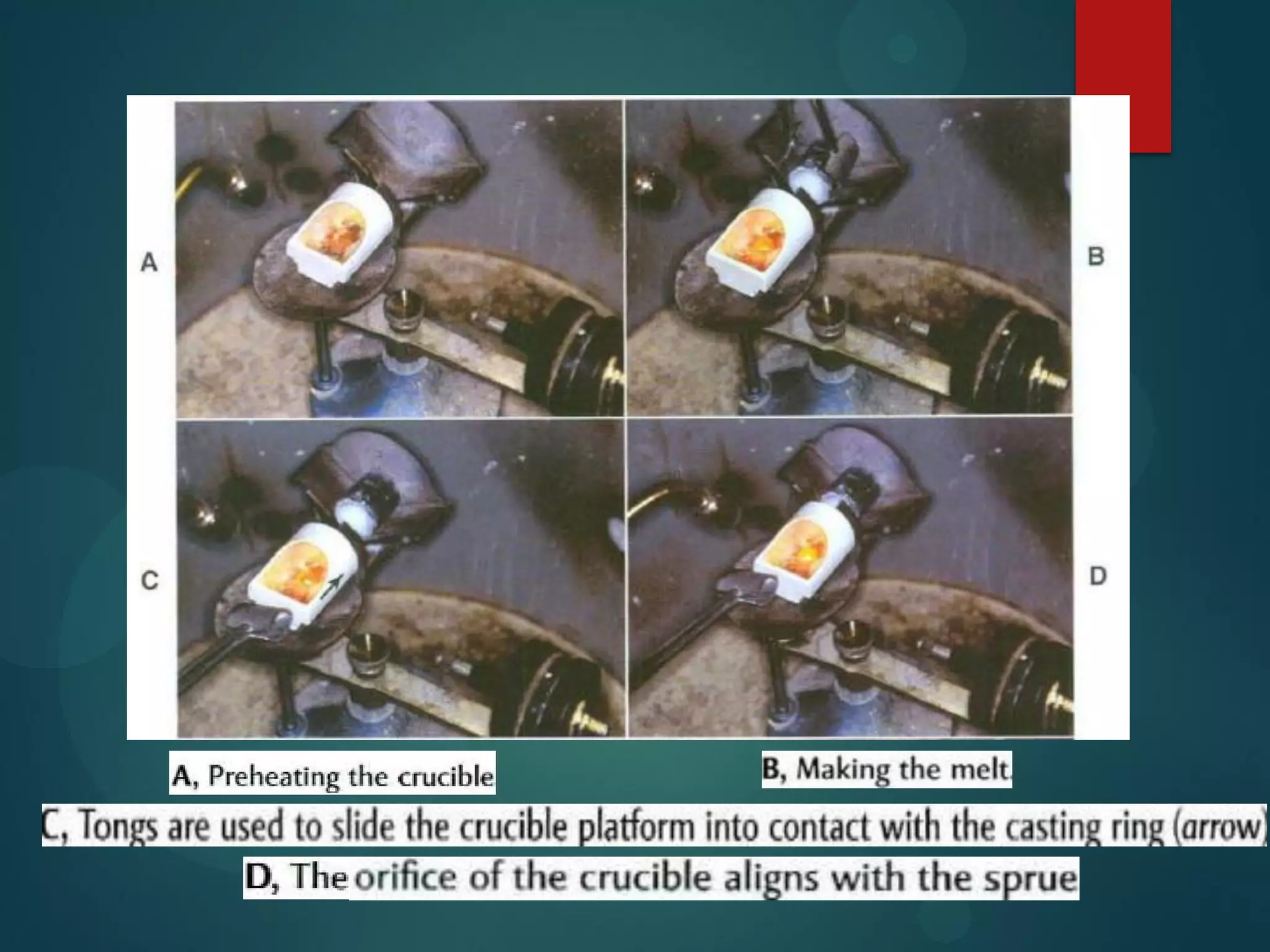

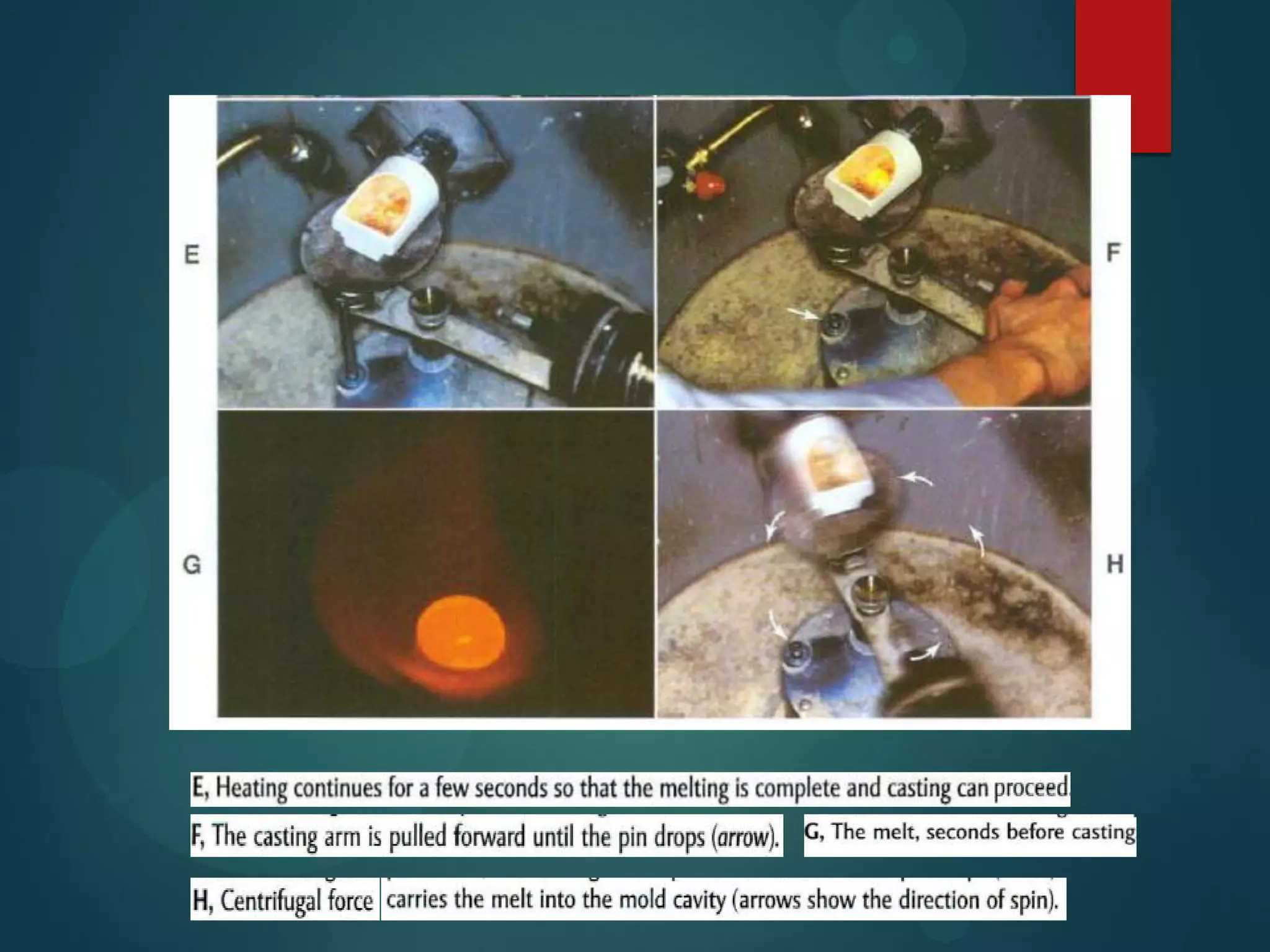

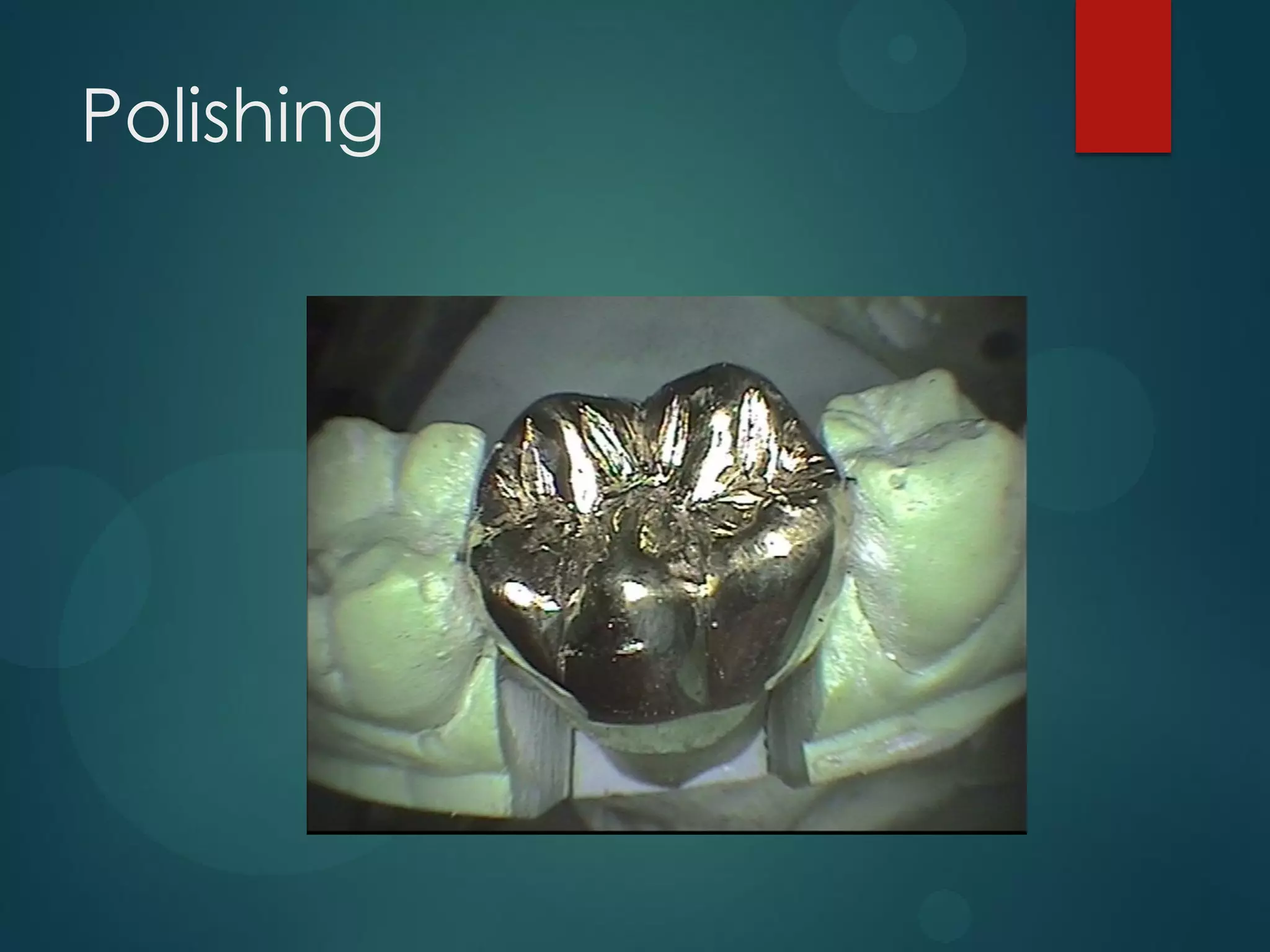

The document provides an overview of the process of spruing, investing, and casting. It discusses constructing a wax pattern, creating a sprue to allow molten metal to flow into the mold, using a casting ring and liner to contain the investment material. It also covers investing materials, the investing process, burnout to eliminate wax, casting including melting alloys and techniques, quenching, pickling, divesting, and finishing processes like polishing. The overall process involves surrounding a wax pattern with a refractory investment material, heating to remove wax, and introducing molten metal to create a dental restoration.