The document discusses the process of investing and casting in fixed prosthodontics. Key steps include:

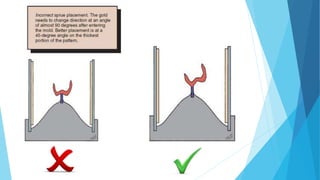

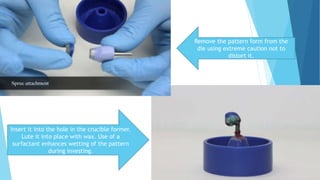

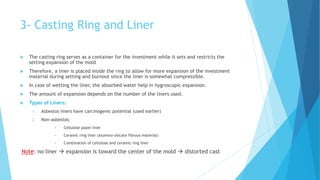

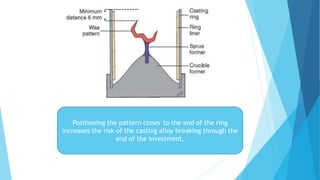

1. Attaching a wax pattern to a sprue former and investing it in dental stone.

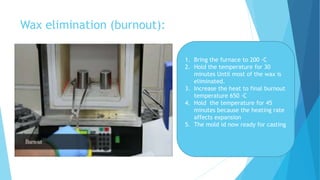

2. Eliminating the wax pattern by heating the stone mold to burn out the wax.

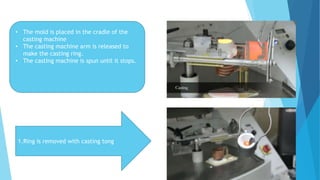

3. Pouring molten dental alloy into the mold cavity using a centrifugal casting machine to produce a dental casting.

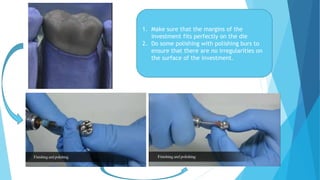

4. Finishing the casting by removing the sprue and investing material and polishing the surfaces.