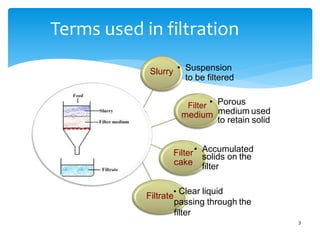

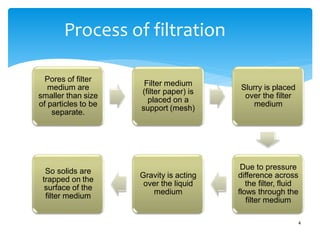

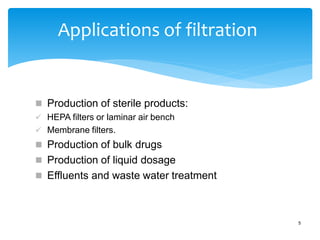

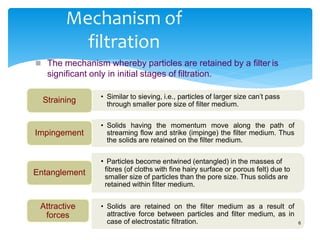

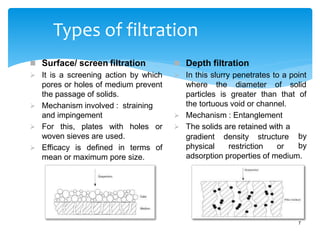

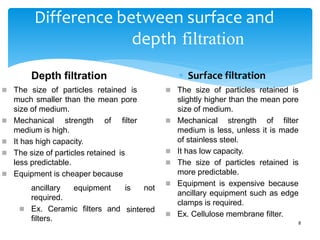

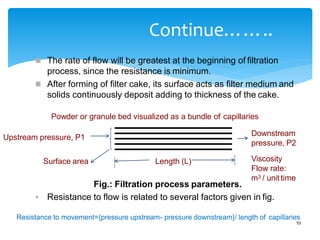

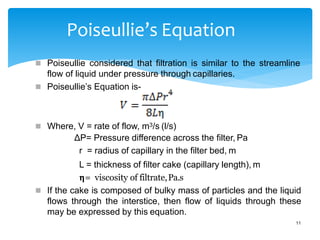

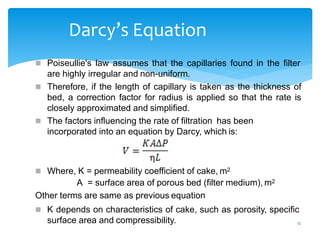

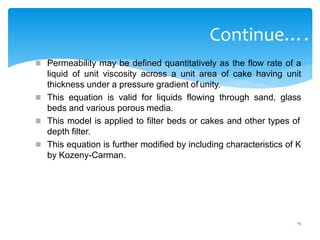

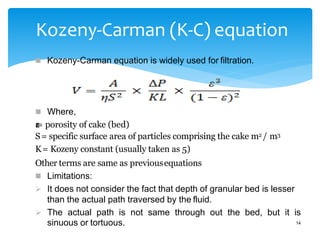

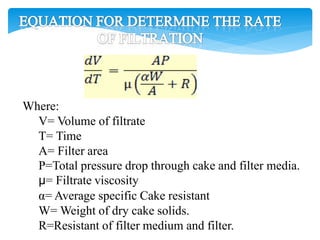

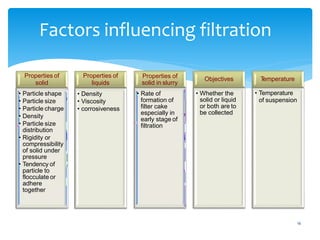

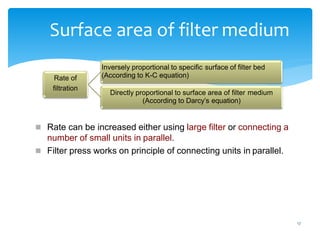

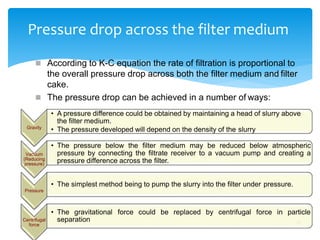

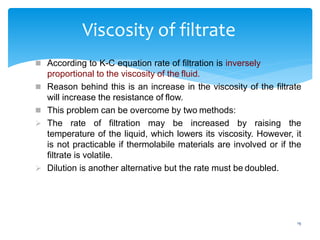

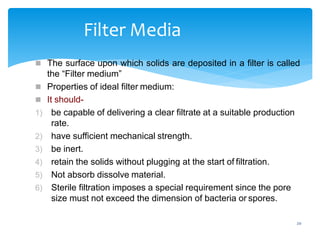

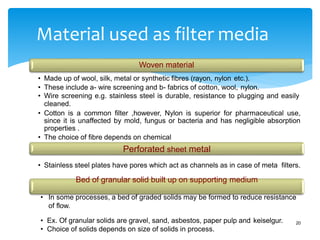

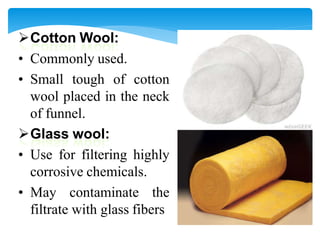

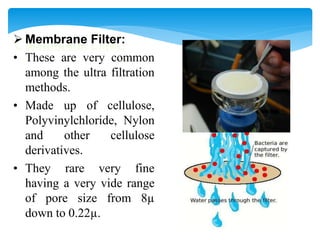

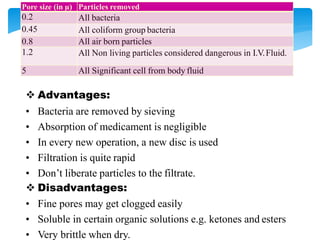

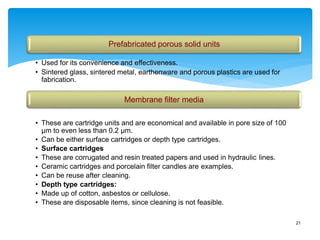

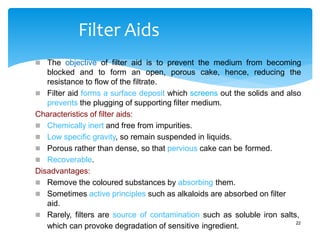

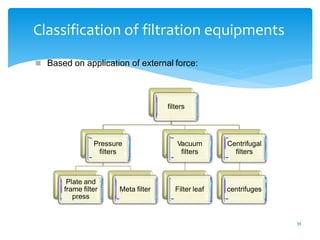

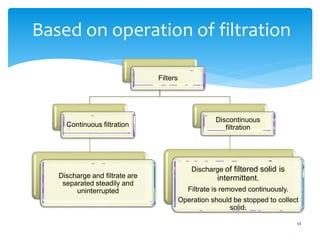

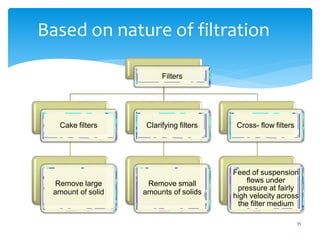

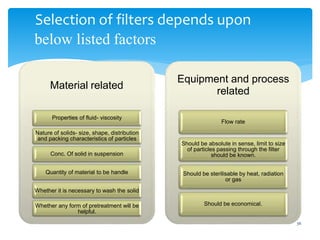

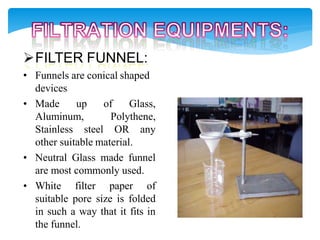

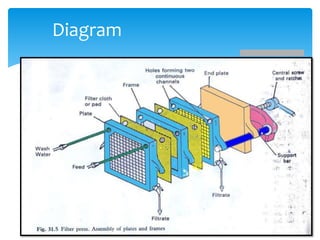

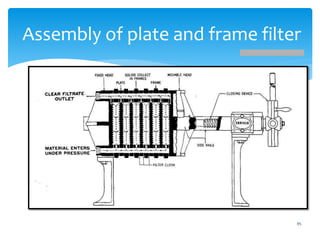

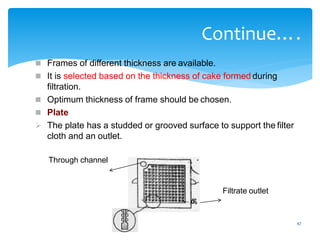

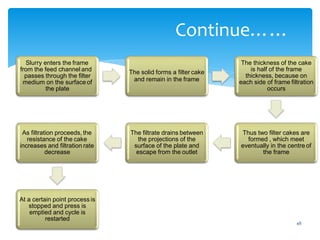

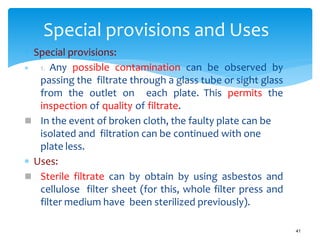

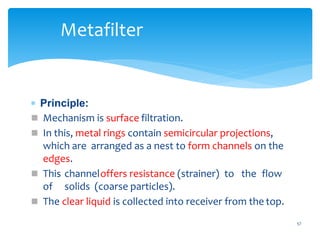

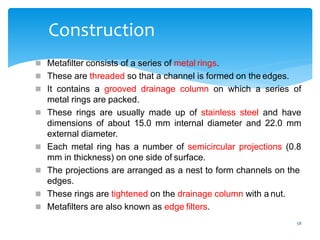

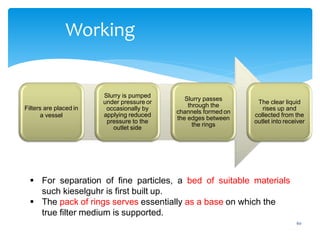

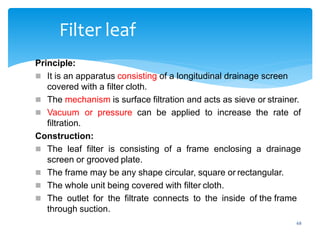

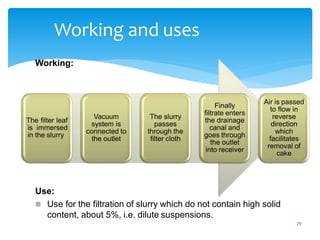

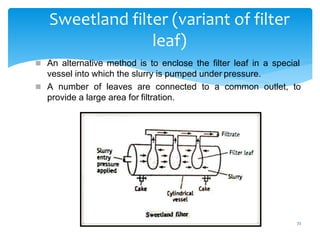

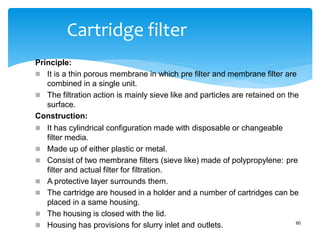

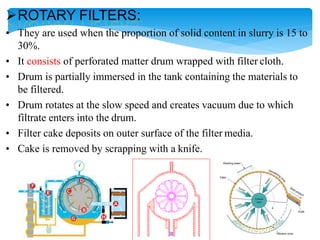

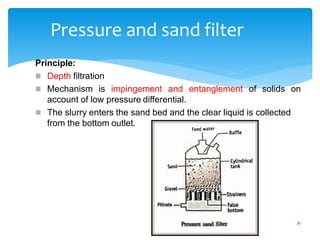

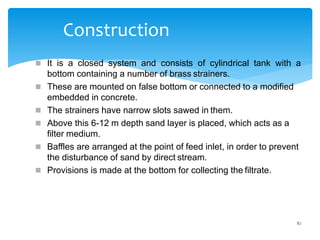

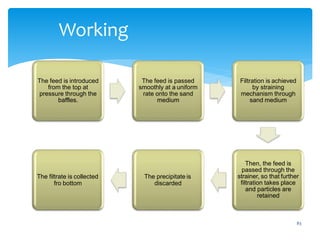

The document discusses filtration and clarification processes. Filtration is defined as the separation of solids from fluids by passing them through a porous medium, while clarification involves separation of very low concentration solids (<1% w/v). Key terms like filter, filtrate, and filter cake are introduced. Common filtration mechanisms like straining, impingement, and entanglement are described. Factors affecting filtration rate include properties of solids, liquids, temperature, pressure, and filter media. Common filter media include woven materials, membranes, sintered materials and filter aids like diatomaceous earth and perlite. Theories like Poiseuille's and Darcy's laws are discussed in relation to modeling filtration rates