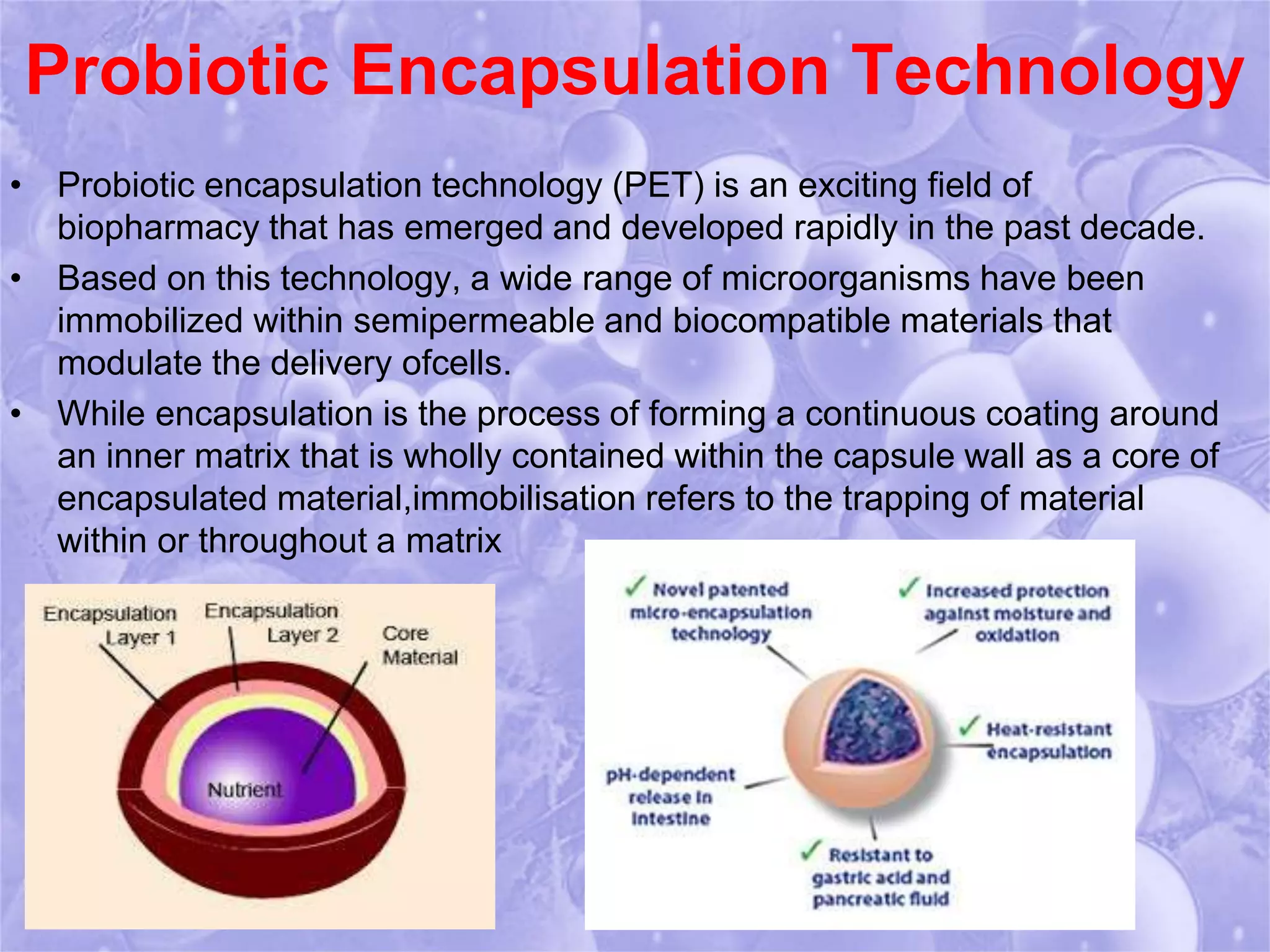

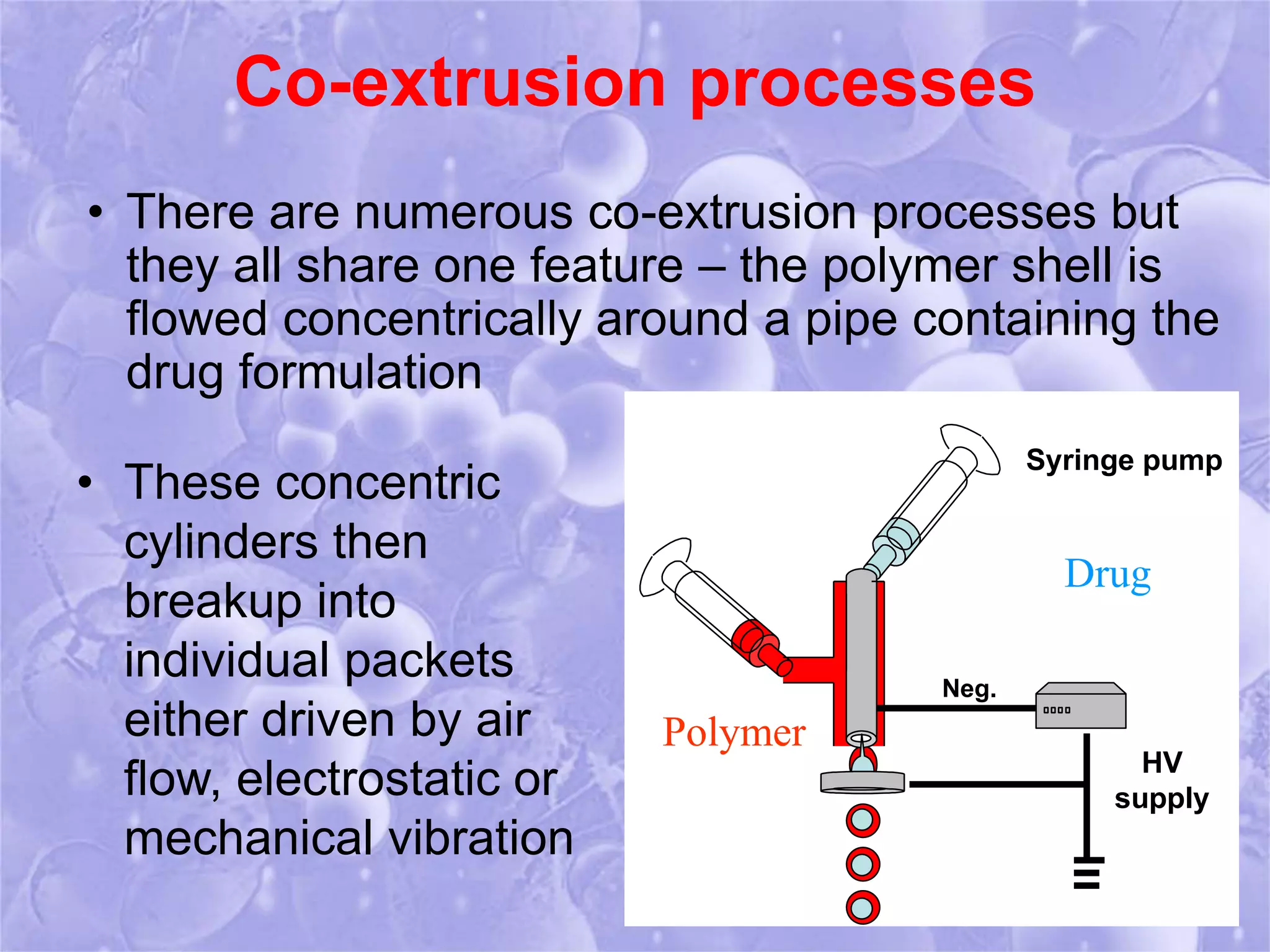

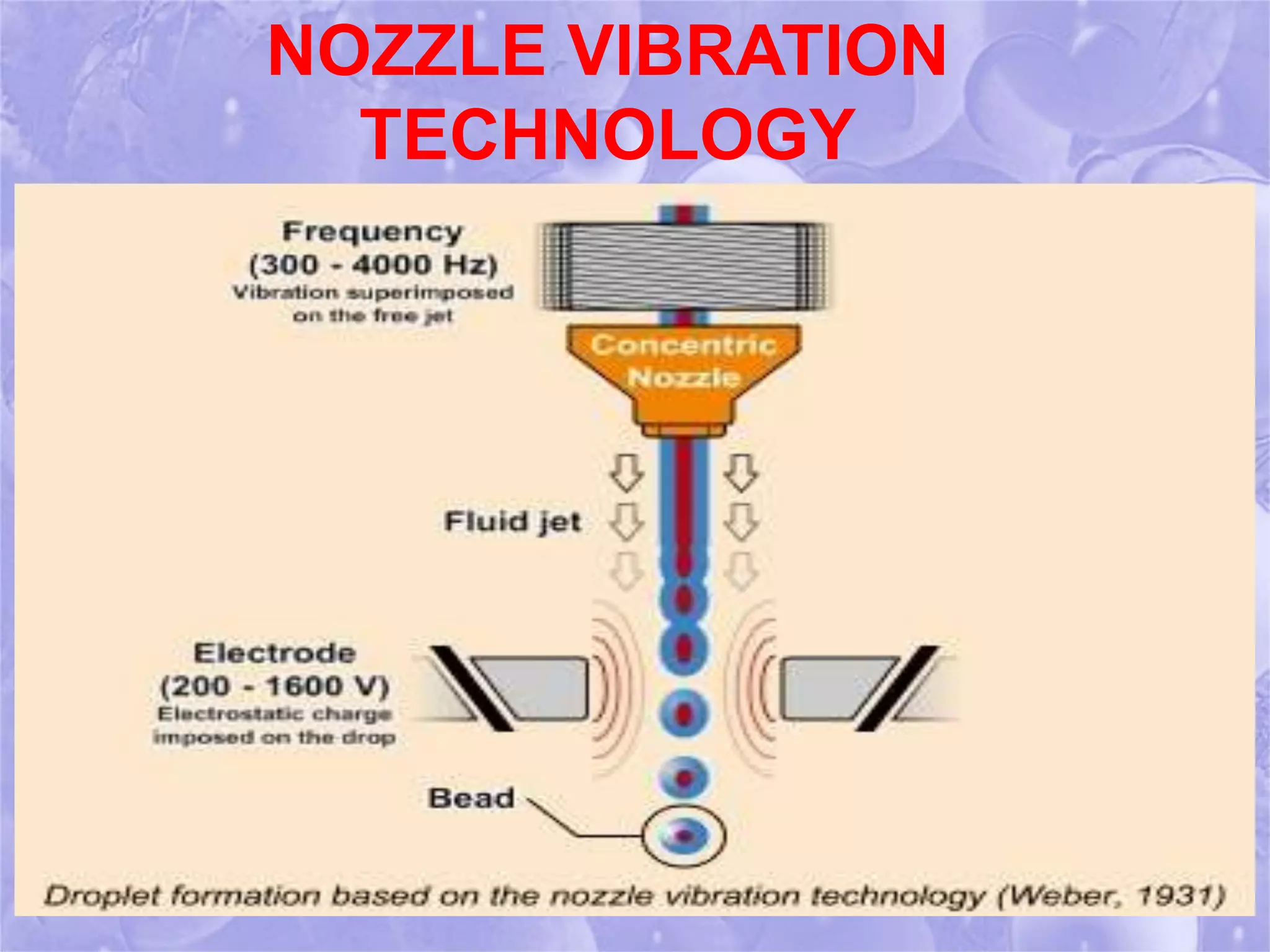

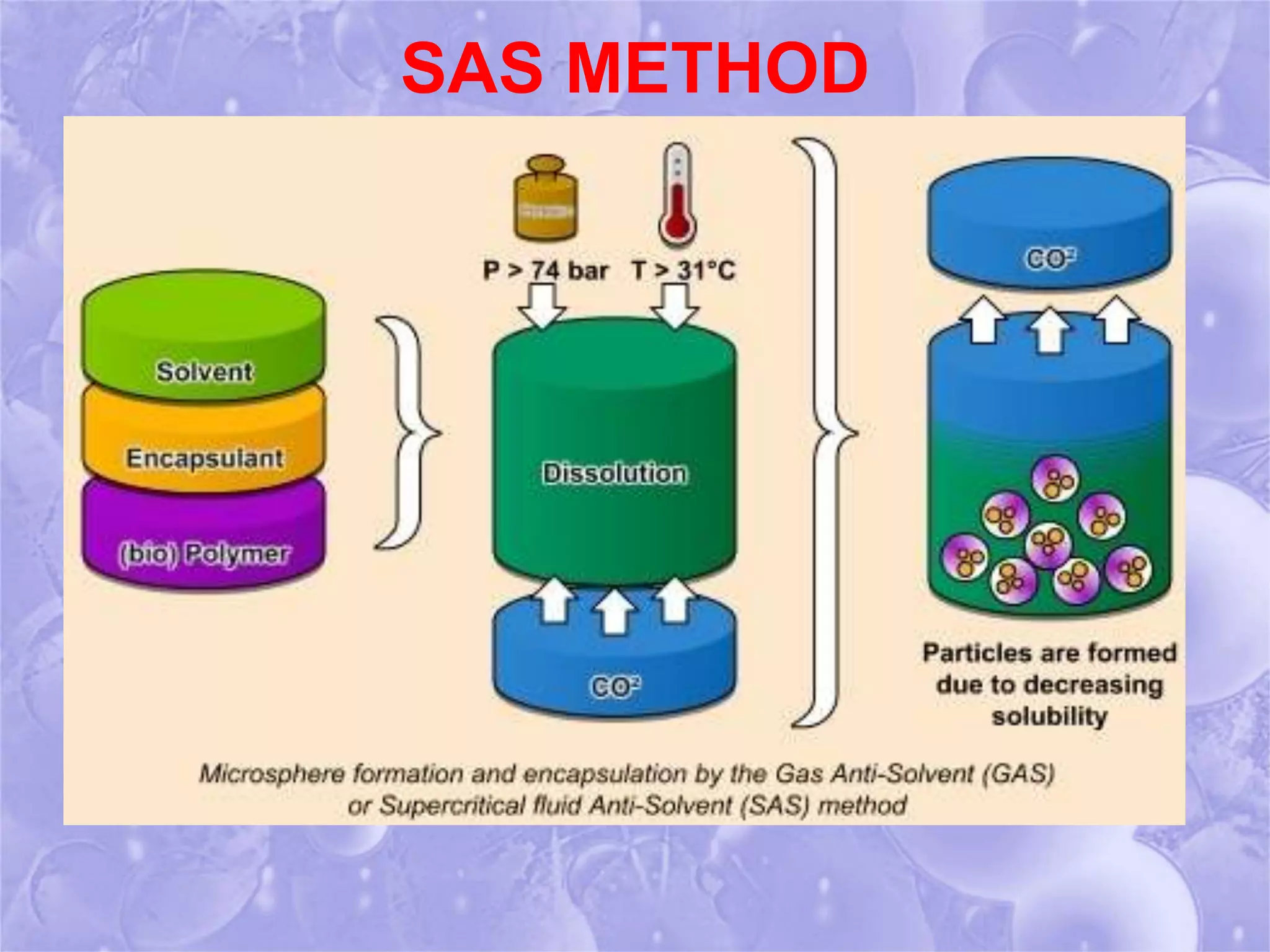

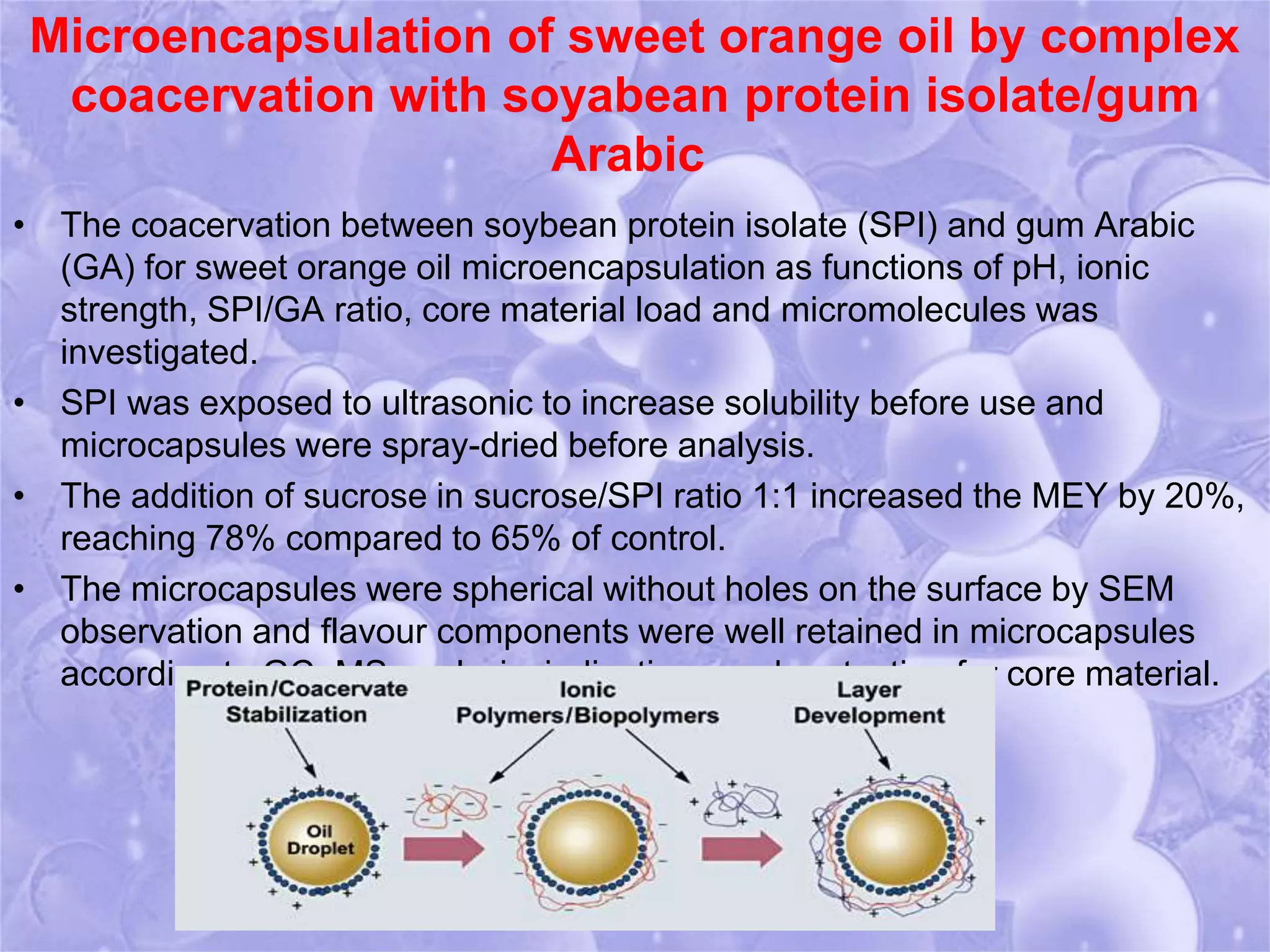

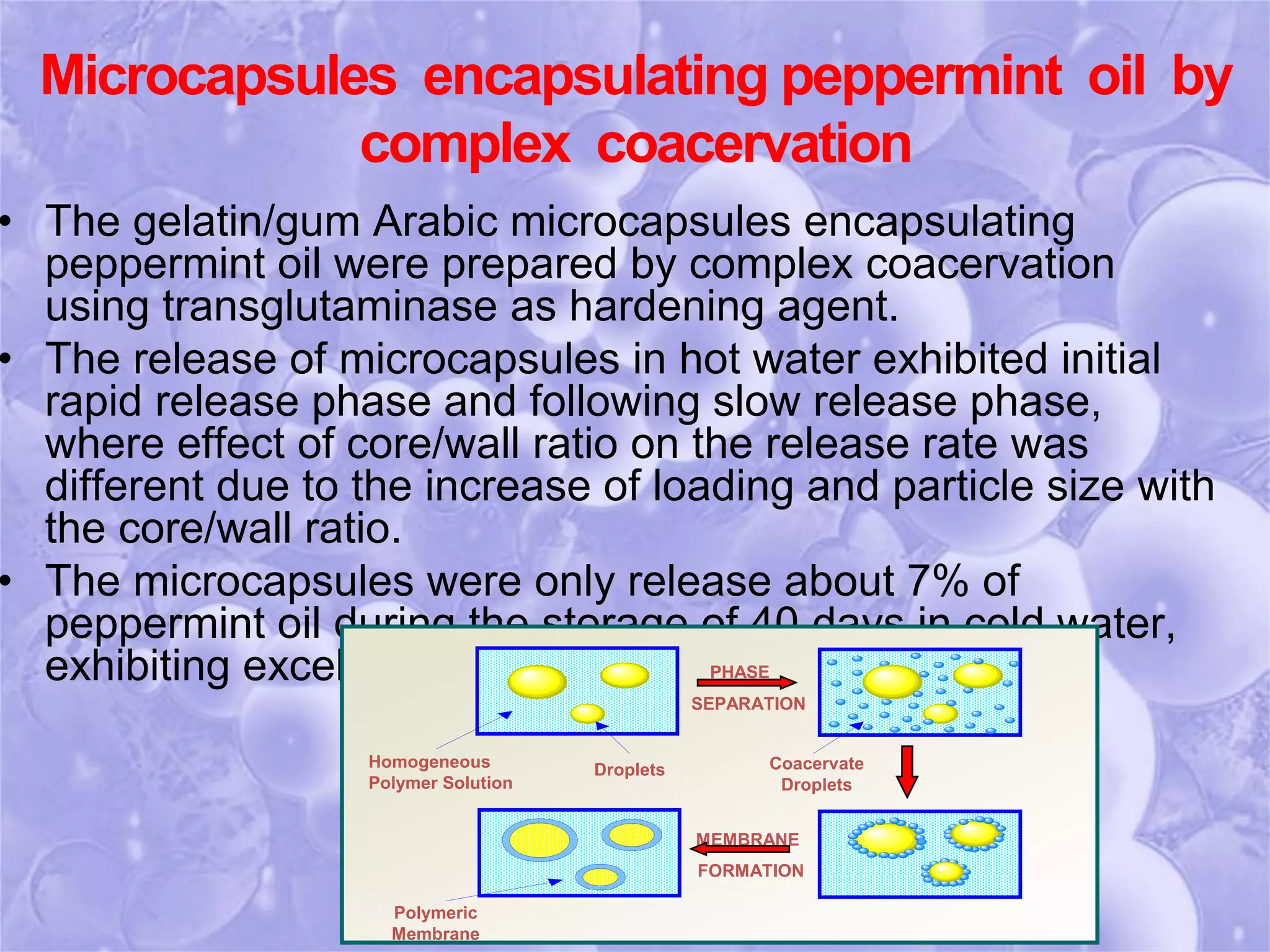

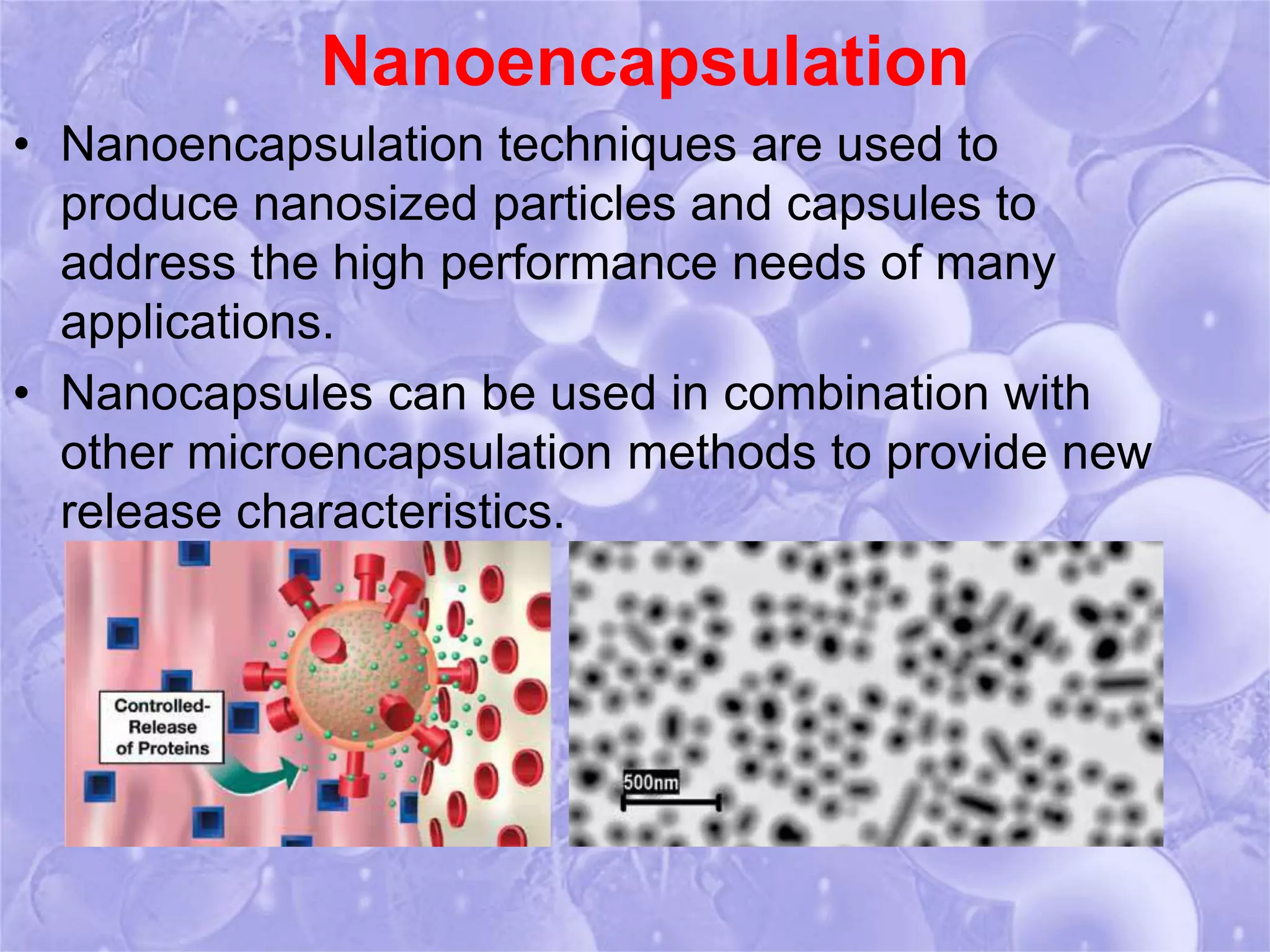

The document discusses various encapsulation technologies used to encapsulate probiotics, food ingredients, and nutraceuticals. It describes techniques like co-extrusion processes and nozzle vibration technology that are used to form capsules. Specific examples discussed include encapsulating sweet orange oil, peppermint oil, and propolis extract using complex coacervation. Microencapsulation and nanoencapsulation techniques provide benefits like improved shelf life, taste masking, and controlled release. The technologies can be used to develop functional foods and nutraceutical products.