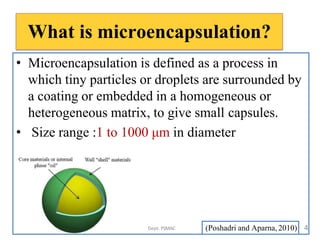

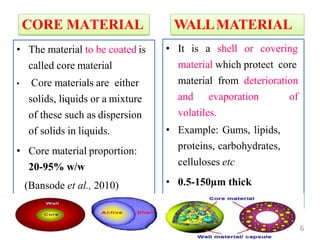

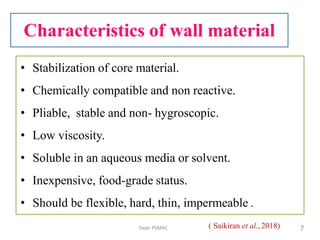

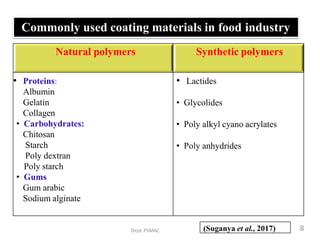

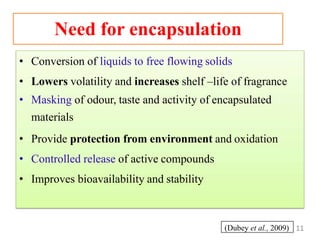

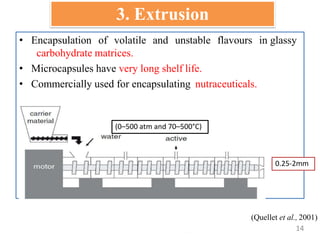

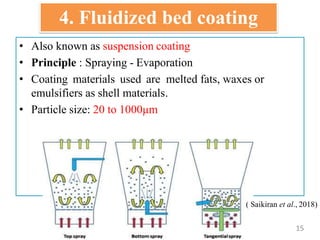

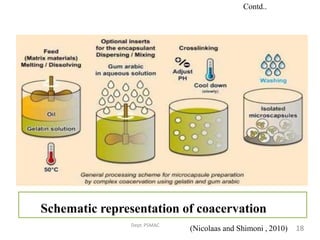

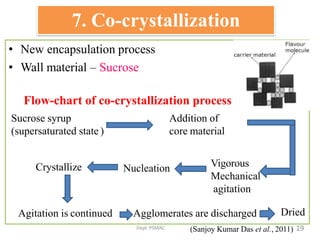

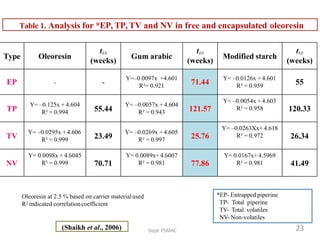

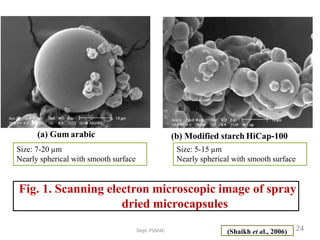

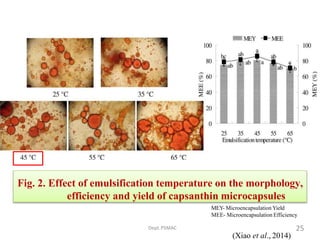

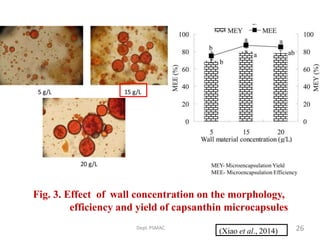

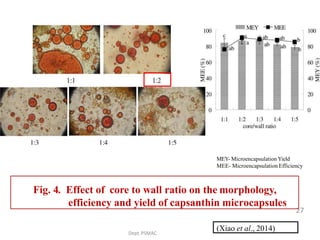

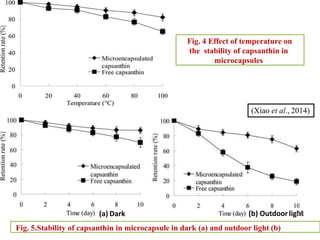

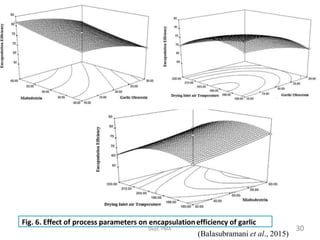

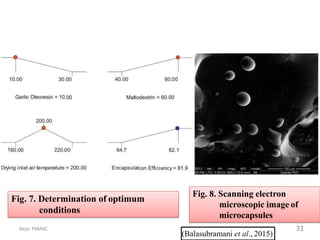

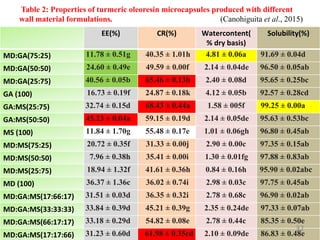

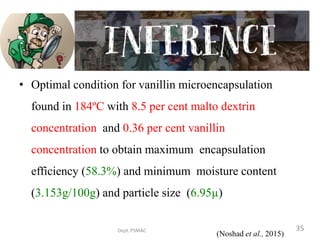

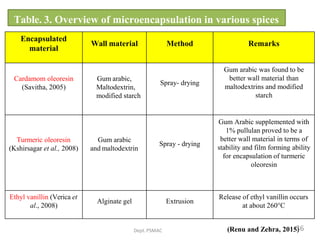

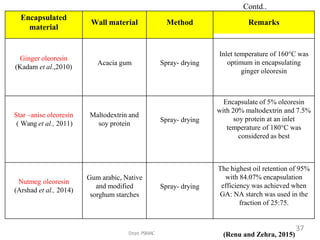

The document presents a seminar on microencapsulation in spices, detailing its definition, history, applications, and encapsulation methods. It highlights the need for encapsulation in spices to enhance shelf-life, protect volatile compounds, and improve stability. Additionally, it discusses various coating materials and the challenges involved in selecting appropriate encapsulation materials.