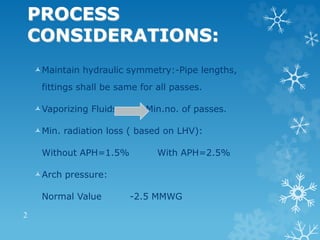

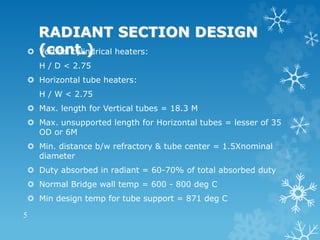

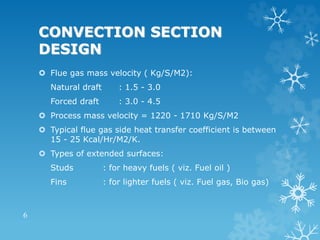

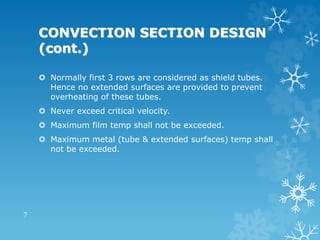

This document provides design considerations and parameters for key components of a fired heater system. It discusses considerations for the radiant and convection sections of fired heaters as well as the forced draft fan, induced draft fan, burners, air preheater, and sootblowers. Maintaining hydraulic symmetry, minimizing radiation losses, and avoiding excessive metal temperatures are some of the important design considerations for the radiant and convection sections. The document also specifies design parameters for components like flue gas velocities and heat transfer coefficients.