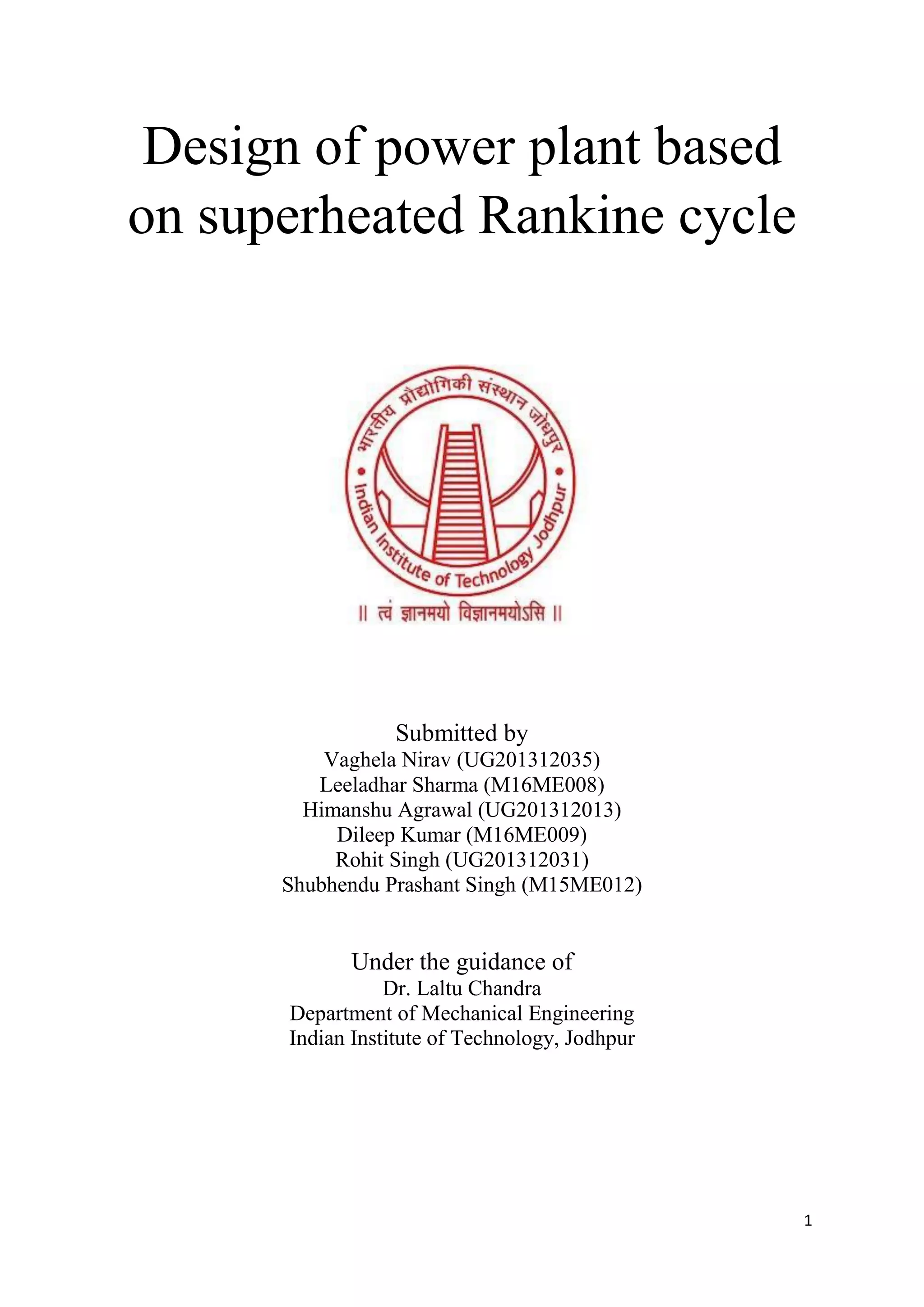

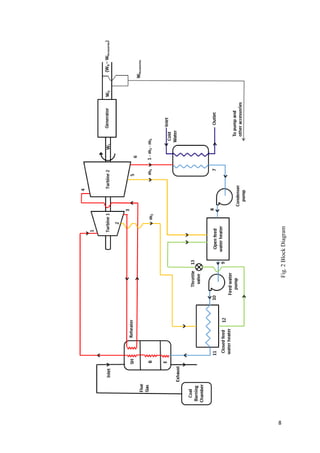

This document describes the design of a 1 MW power plant based on a superheated Rankine cycle. Key components include a steam generator with economizer, boiler and superheater sections, a high pressure turbine operating from 100-20 bar, a low pressure turbine from 20-0.1 bar, a condenser, an open feedwater heater containing a deaerator, a closed feedwater heater, and a reheater. Thermodynamic calculations are shown to select locations and operating conditions for these components. Performance is calculated with a net work output of 968.28 kW, heat input of 2557.14 kW, and heat rejected of 2358.52 kW.