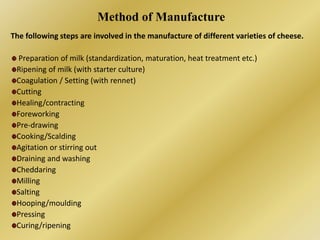

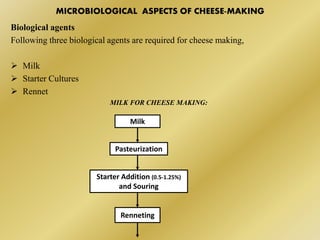

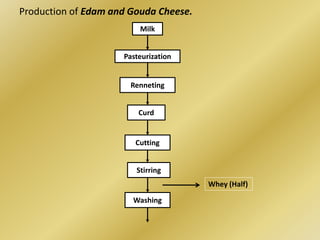

Cheese making is an ancient process that involves coagulating the casein in milk using rennet or lactic acid to produce curd. The curd is then pressed, shaped, and aged to produce different varieties of cheese. The document discusses the key steps in cheese making including preparation of milk, addition of starter cultures, coagulation, processing the curd, salting, and ripening. It also describes the major types of cheeses classified by moisture content and ripening method as well as the microorganisms involved and physical changes that occur during the ripening process.