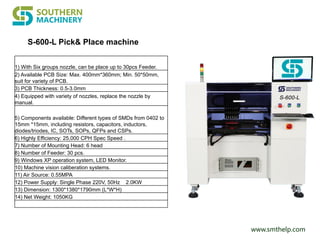

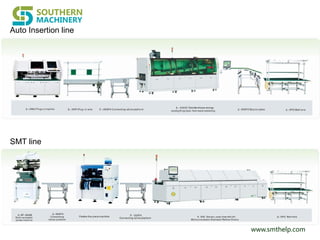

The document provides detailed specifications for various SMT (Surface Mount Technology) machinery offered by Shenzhen Southern Machinery Sales and Service Co., Ltd, including pick & place machines, auto insertion machines, and reflow ovens. It includes specific models, their capabilities, dimensions, and performance metrics such as speed and accuracy. Additionally, it mentions customized solutions and support for various electronic components in the manufacturing process.