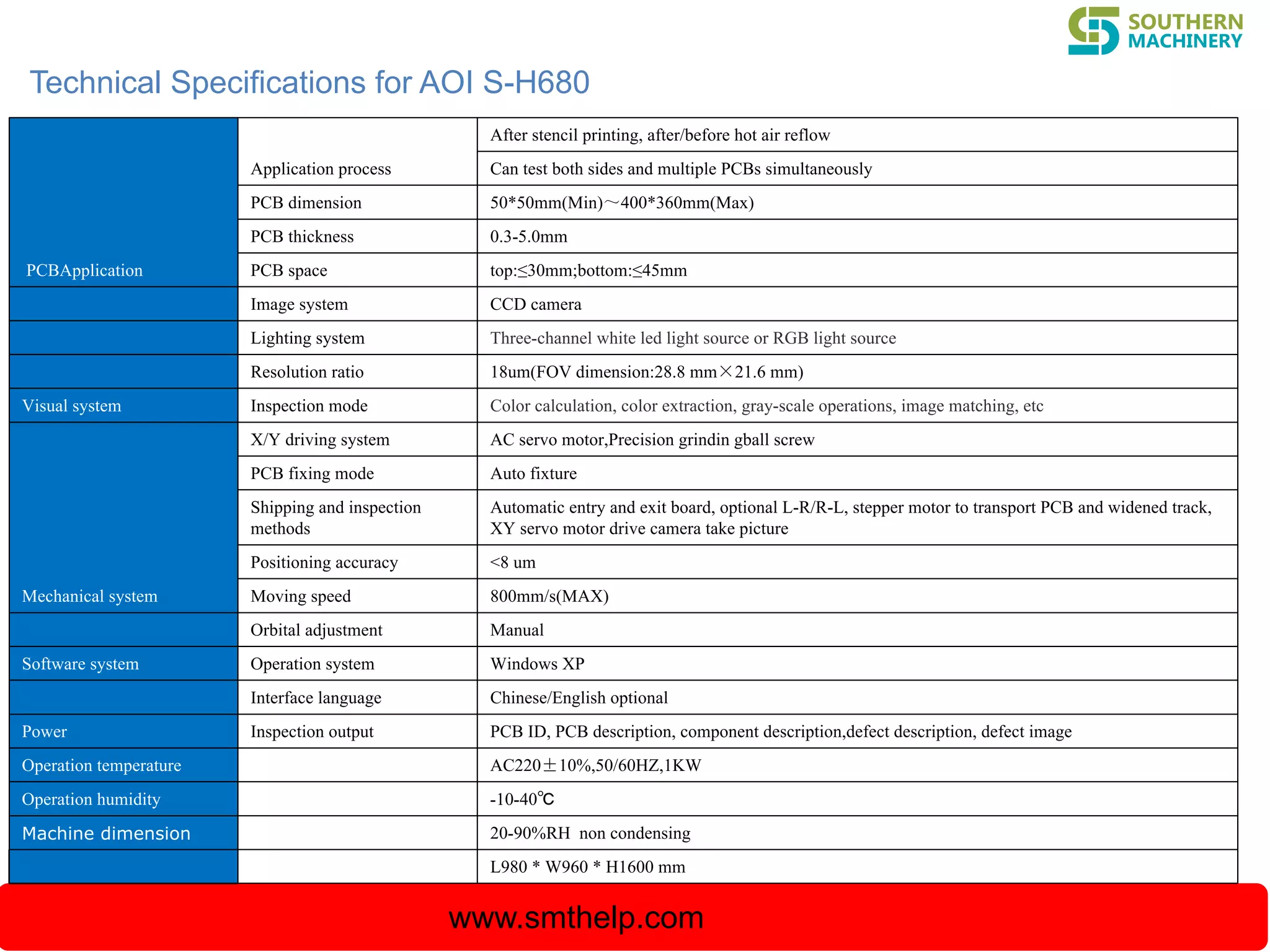

This document provides information about an automated optical inspection (AOI) machine. It can inspect printed circuit boards (PCBs) after stencil printing for issues like solder paste availability and positioning. It also inspects PCBs before and after reflow soldering to check for problems like missing or misaligned components. Key features include high-resolution CCD cameras, RGB light sources, precision movement system, and output of inspection reports. It provides automated inspection of various stages of the PCB assembly process.